MAINTENANCE GUIDE

5.1

To keep your sprayer in optimal condition, keep the following parts always greased: shut-off O rings, Piston sleeve, Pump tube O rings,

Plunger O rings, Nozzle O ring.

Wash the sprayer inside and outside with fresh water, to be able to handle it without contamination risk.

It is recommended to replace all wear parts when performing a repair job:

- Piston sleeve, - Shut-off O rings, - Pump tube O rings, - Plunger O rings,

- Nozzle O ring - Nozzle gasket

NOTE:

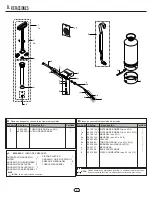

Instructions for compression sprayers:

1.-

Change the wear parts in the pump tube, shut-off, spray lance and nozzle if your sprayer is leaking or as preventive maintenance.

2.-

Unscrew the nut between spray lance and shut-off.

3.-

Change gasket located between nut and shut-off.

4.-

The shut-off is comprised by several pieces, remove the lower plug and replace gasket, remove plunger and replace the two o-rings and gasket. Lubricate

before assembly.

5.-

Unscrew the nozzle and replace O-ring and gasket, lubricate.

6.-

Remove the pump tube from the tank and replace O ring located in the upper part, lubricate before assembling.

7.-

Remove screws of the pump tube, remove handle, in the lower part replace and lubricate the the piston sleeve.

Remove the antenna from the lower end of the pump tube and replace the O ring.

To lubricate all parts; Use

silicone-based grease.

NOTE:

ATTENTION

LUBRICATE THE PUMP TUBE

BEFORE ASSEMBLING

4

COMMON PROBLEMS, POSSIBLE CAUSES & SOLUTIONS

6.

PROBLEM

The piston does not slide easily and there is noise

between the pump tube and the piston.

CAUSE

SOLUTION

There is no lubrication between the pump

tube and the piston sleeve.

Check the piston sleeve. If it is worn-down

replace it and grease it, if not just grease

the edges.

The pump system leaks.

The antenna does not seal correctly in

the seat of the pump tube.

Check the antenna and if necessary replace

the seal. Lubricate before reassembling.

Shut-off leaks after releasing the handle.

The O rings of the shut-off plunger are

worn-down or swollen.

Replace and grease the new O rings and

plunger

The sprayer is pressurized but there is no flow when

pressing the shut-off handle.

The pump tube is not tight enough.

Loosen the hose clamp and check if the hose

or the tank outlet are clogged and if so,

proceed to unclog them with pressurized air

or water

Although the sprayer is being pumped vigorously it does

not build pressure.

The hose is clogged.

Tighten the tube and grease the O ring.

2

3

5

6

7

7

4