Operating instructions

6

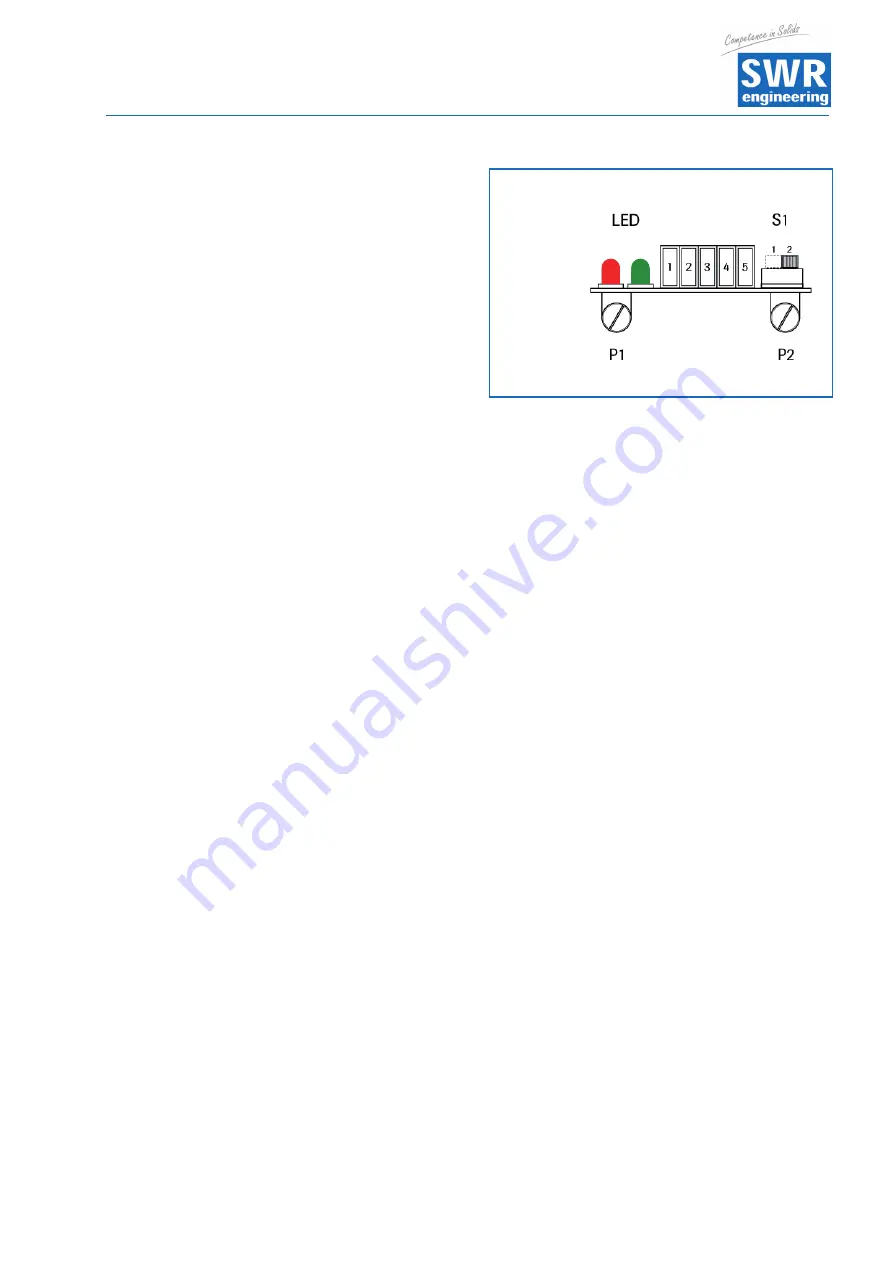

5. Commissioning

All necessary control elements for the alignment

are in the receiver.

P1:

Adjustment of the sensitivity

P2:

Adjustment of the time delay of the

signal.

S1:

Doubling of the sensitivity

(Pos. 1 = normal sensitivity and

Pos. 2 = double sensitivity

LED red: the flashing shows the signal intensity.

•

fast flashing = high signal intensity

•

slow flashing = low signal intensity

•

LED out = no signal received

LED green: indicates the switching status of the relay.

•

LED on = relay closed

Adjustment of the signal threshold with Potentiometer P1

With the potentiometer P1 the signal threshold can be adjusted, to that the relay should switch.

The microwave barrier is adjusted in such a way that clear distinctions between interrupted or damped

resp. not-interrupted microwave beam are made.

Proceeding

: With not-interrupted beam and

flashing red LED

turn P1 against the clockwise to the relay

switches and at the same time the LED shines green. Now interrupt the beam path (put the material to

be detected between the transmitter and the receiver) and turn P1 only so far clockwise until the green

LED goes out. Repeat this procedure. If the green LED still lights, even with a complete left turn of P1, and

furthermore the material has a low dielectric constant and weak damping (e.g. paper, plastics, foams, etc.),

please contact SWR engineering GmbH

If the red LED should not light, put the switch S1 to position 2, with it the delicacy is doubled.

If the LED does not light even in this most sensitive position, then the receiver does not get any signal from

the transmitter. In this case examine the microwave barrier for faultless function by clarifying the following

possibilities:

•

Wrong adjustment of the barrier to each other

•

The distance between transmitter and receiver is too large

•

Too much damping material in the beam path

•

Damping built-up at the sensors

Adjusting of the switch response time Potentiometer P2

Finally adjust the switch response time with the potentiometer P2 according to your requirement between

the range of 0.25 and 5 seconds. By turning P2 anticlockwise, the delay increases. Thereby a fluttering of the

relay can be stopped, which have been produced by critical adjustment of the sensitivity.

Fig. 4: Receiver

P1

Sensitivity fine

P2

Response time

S1

Sensitivity rough

LED red

Field intensity

LED green

Switching status

plug

NC NO COM

¤ ¤ ¤

¤ ¤

Power supply