第

18

页

故障排除

TROUBLESHOOTING

问题现象

Symptom

原因

Cause

对策

Solution

送带机异常振动

Abnormal vibration

1.支架各固定螺丝松弛

2.灵敏度值过高

1.Fixed screw loosen

2.The value of Sensitivity is too high

1.上紧松弛的螺丝

2.降低灵敏度值

1.Check and Tighten the screws

2.Lower the value of sensitivity

送带数值 999 仍然过紧

999 still too tight

1.感应杆有异物接触碰撞

2.感应值不在正常范围

1.Something contact with the sensor bar

2.The sensor is not at the working range

1.请将异物移除

2.参照归零校正,如果不在 10-90 范围内,

通知维修人员进行维修

1.Remove the irrelevant object

2.Redo the 0kg calibration.Call the technician to

maintain if the value is not between 10-90

送带数值 001 仍然过松

001 still too loose

送带机无动作

No signal

1.电源未接妥

2.线路系统断路

3.控制系统故障

1.power is not connected properly

2.Connected line is break

3.Electronic control system error

1.参考接线图接好电源

2.检查各线路插座与插头接角是否松脱

3.通知维修人员进行维修

1.Refer to wiring diagram connecting the power

2.Check the pin of connecting plug or socket are

not close

3.Call the technician to maintain

荧幕不显示

Blank panel

面板故障

Panel out of order

通知维修人员进行维修

Call the technician to maintain

模式数值无法记忆

Cannot memorized the mode

记忆体故障

Memory out of order

通知维修人员进行维修

Call the technician to maintain

启动后,松紧带无法

回拉至所设计的松紧带

After turn on the power,

The elastic tape can not

Back to reach the setting

tension

无张力开关

动作不正常

Switcher of Free Tape is not working

Properly Un-plug the Switches of Free Tape

请拆下无张力开关的电源插头后,若可正常回拉

则表示:

1.无张力开关位置不良,应调整

2.无张力开关故障,通知维修人员维修

If the elastic tape can pull back normally,

it means:

1.The position of Switches if Free Tape is not in

good position,Please re-adjust

2.The Switches of Free Tape is out of order,

call the technician to maintain

车缝不准确

Unstable Elastic

Size Control

1.进带过程不流畅:

1-1.限宽环太宅造成送带过程产生阻力

1-2.车缝时松紧带与车头或其他物体接触产生摩擦

1.Un-smooth feeding path way for the Tape:

1-1.The width of Elastic Guide Rings for the Tape is too narrow to

feed the tape

1-2.The Elastic Tape contacts to the Machine Head or other

obstacle which causes friction

1-1 无压脚导引靠边器及压脚上之限位装置均需要调整

略宽松于松紧带(注:如因此造成车缝时松紧带左右移

位时,请调整限宽环的正确位置)

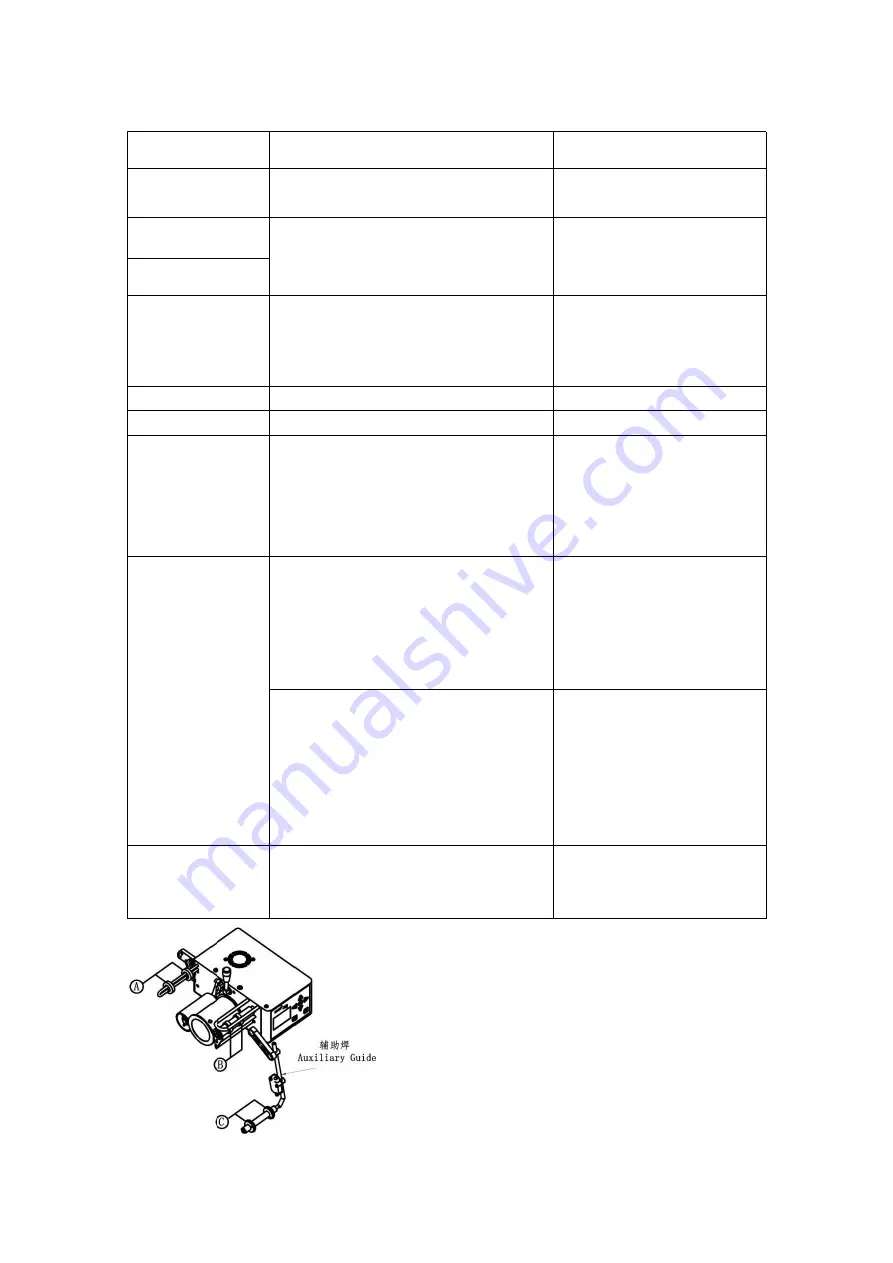

1-2 调整辅助杆,将所有松紧带隔离所有接触的车头或

物体

1-1.Adjust the proper width of All Guide include

on the Pressure Foot(P.S. Pls.Re-location of Elastic

Guide Rings,if the Tape is sliding to the right or

left irregularly

)

1-2.Use Auxiliary Roller to prevent the from

contacting the machine or other obstacle

2.灵敏度调整不当

3.缝制员手势熟练度及布料裁剪尺寸不均

2.Improper Sensitivity Setting

3.Unskilled operator and Irregularly cutting

2.依松紧带材质的伸缩性调整灵敏度,伸缩度越大灵敏

度调整需越高,但如果调太高灵敏度时会产生主机颤动

不止,而太多则会反应延缓产品尺寸的准确度

3.缝制员在车缝过程中,应保持手势给予布料一致的压

力,不可忽松忽紧,且布料的裁剪尺寸要一致。

2.Pls.Re-setting the Sensitivity.More flexible tape

is with higher value.It will cause vibration,if the

value is too high.However,Lower value setting

may cause slow reaction and causes incorrect

tension

3.Operator must remain the same pressure to

handle the sewing material and the cutting must

be the same size

松紧带已经很松,但车缝

布料的效果仍然有缩皱无法平坦

Can not reach Flat sewing

(Some situation need Flat

sewing result)

因缝纫机的前差动齿,差动太多,送过多的布料

There is with too much differential Feed Ratio in order to feed too

much material

调整缝纫机差动齿轮与主动齿的差动比为同步(1:1)

Pls. Re-adjust the Differential Feed Ratio to

1: 1 range