10

COMMISSIONING AND MAINTENANCE

b

If copper piping has been used and joints have been

hot brazed, flush out the system to remove any braz-

ing residues. Seal test the system after you have

flushed it out.

b

The solar circuit must be immediately filled with a

mixture of water and glycol, that avoids freezing and

corrosion.

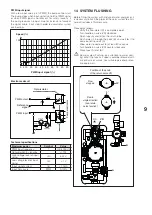

15 SYSTEM FILLING COCK

Before filling the system:

- Cut power off to the solar station and to the connect-

ed integration system, by setting the system's main

switch and the device's main switch to OFF

b

Always use a mixture of water and glycol suitable for

solar applications. Choose the mixture according to

the minimum temperature that can be reached at the

installation site and to the maximum service tempera-

ture of solar collectors. For further information, please

refer to the glycol safety data sheet.

When using glycol not pre-mixed:

- Do NOT part fill the circuit with pure glycol then add

water later.

- Ensure that filling water characteristics comply with

prevailing regulations; if that is not so, filling water

must be treated. Use portable treatment systems, for

instance. In particular, when chlorine content is very

high (> 50ppm) you must use distilled water for the

mixture.

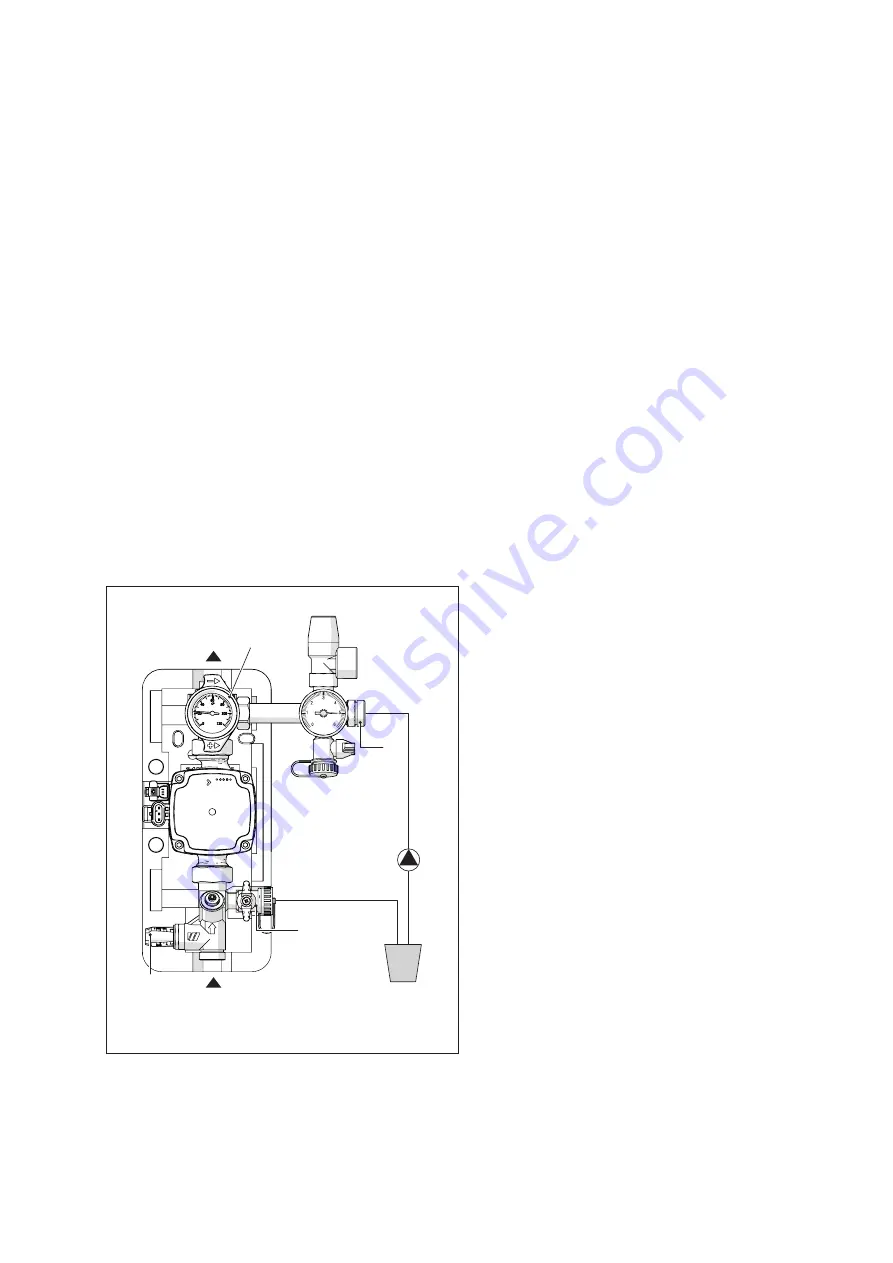

VR

B

A

C

Mixture

of glycol

and water

PC

PC

Heat transfer fluid filling pump

To fill the system, proceed as follows:

- Verify the flow-meter (C) is completely open

- Connect the filling pump (PC) as shown

- Turn handle on valve (VR) clockwise

Open taps (A) and (B) on the return tube

- Open manual degassing tap and any bleeder valve,

located at the highest points of the system, and keep

them open throughout the filling procedure.

- Pump the heat transfer fluid around the circuit with an

external filling pump until all air bubbles have been

eliminated. Close the manual bleed valve and any

vent valves opened previously.

- Turn handle on valve (VR) counter clockwise

- Temporarily raise the pressure in the system to 4 bar.

- Start up the system for about 20 minutes.

- Repeat air bleeding operation until system is com-

pletely free of air bubbles.

- set the system pressure.

- Close taps (A) and (B).

b

The set pressure must ensure that the one measured

at the solar collectors is positive with respect to the

ambient one (avoid depression in the solar field) and

must be set considering both the safety valve open-

ing pressure (6) and the solar expansion reservoir

pre-charge pressure. To set the system pressure cor-

rectly, refer to the design manual.

a

Do not fill the system in bright, sunny conditions or if

the collectors are hot.

b

Use a manual bleed valve, which should be installed

at the highest point in the system, to ensure that all air

bubbles have been eliminated from the circuit.