1-6-7

T7500EA

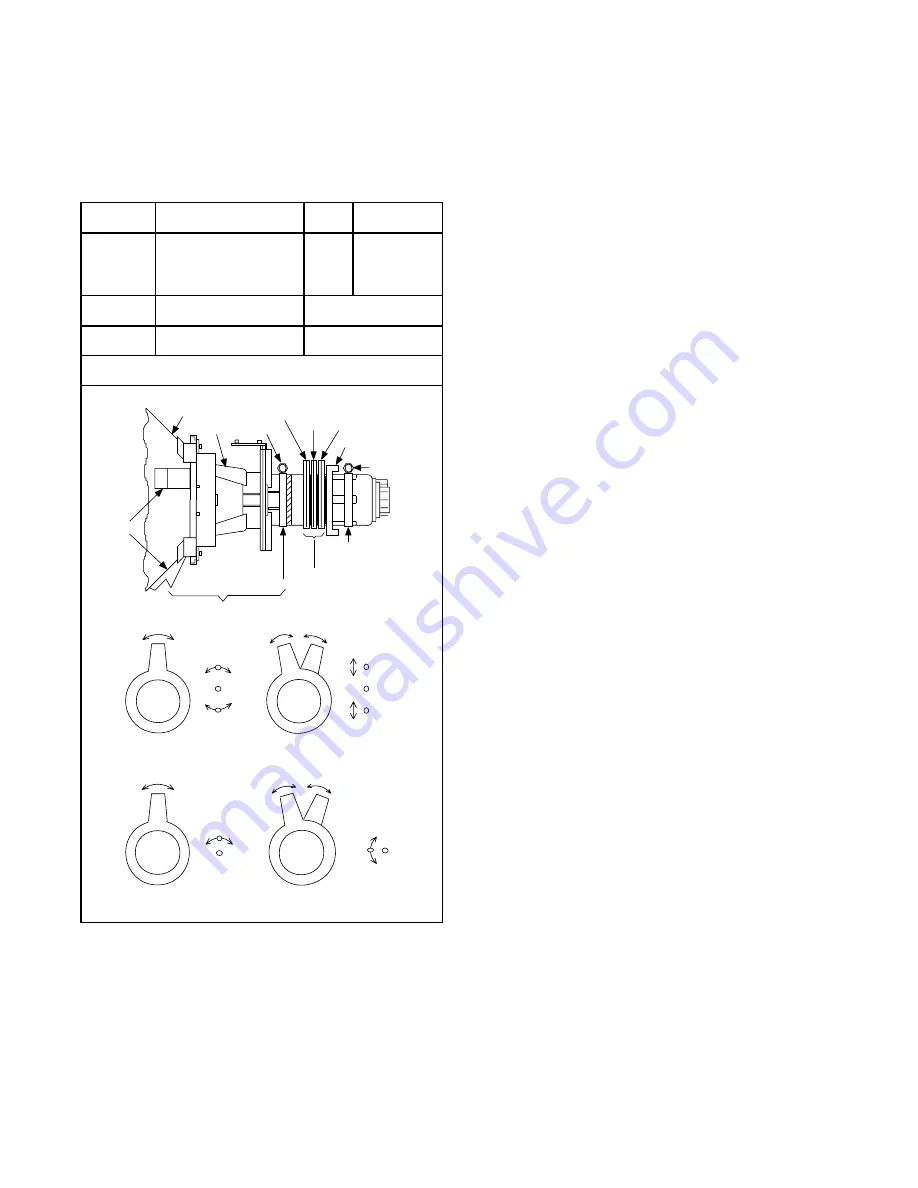

13. Convergence Adjustment

Purpose:

To obtain proper convergence of red, green

and blue beams.

Symptom of Misadjustment:

If Convergence Adjust-

ment is incorrect, the edge of white letters may have

color edges.

1. Set the unit to the AUX mode which is located

before CH2 then input a Dot or crosshatch pattern.

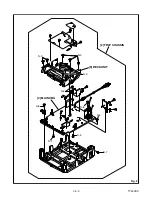

2. Loosen the Ring Lock and align red with blue dots

or Crosshatch at the center of the screen by rotat-

ing (RB) C.P. Magnets. (See Fig. 7.)

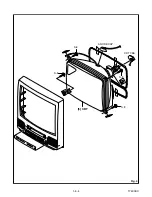

3. Align red / blue with green dots at the center of the

screen by rotating (RB-G) C.P. Magnet.

(See Fig. 8.)

4. Fix the C.P. Magnets by tightening the Ring Lock.

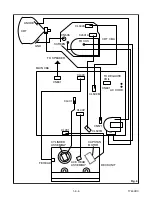

5. Remove the DY Wedges and slightly tilt the Deflec-

tion Yoke horizontally and vertically to obtain the

best overall convergence.

6. Fix the Deflection Yoke by carefully inserting the DY

Wedges between CRT and Deflection Yoke.

Test point

Adj. Point

Mode

Input

---

C.P. Magnet (RB),

C.P. Magnet (RB-G),

Deflection Yoke

---

Dot Pattern

or

Crosshatch

Tape

M. EQ.

Spec.

---

Pattern Generator

See below.

Figure

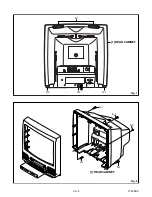

DY WEDGE

DEFLECTION YOKE

C.P. MAGNET

RING LOCK

SCREW

SCREW

RB-G

RB

PURITY

CRT

COIL

COIL CLAMPER

C.P. MAGNET

CLAMPER

Fig. 6

Fig. 7

Fig. 8

B

G

R

R

G

B

C.P. MAGNET (RB)

RB

G

RB

G

C.P. MAGNET (RB-G)