1-3-4

TD204IMP

Safety Check after Servicing

Examine the area surrounding the repaired location

for damage or deterioration. Observe that screws,

parts and wires have been returned to original posi-

tions. Afterwards, perform the following tests and con-

firm the specified values in order to verify compliance

with safety standards.

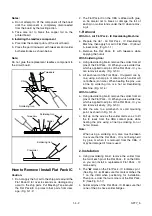

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d') between sol-

dered terminals, and between terminals and surround-

ing metallic parts. (See Fig. 1)

Table 1 : Ratings for selected area

Note:

This table is unofficial and for reference only.

Be sure to confirm the precise values.

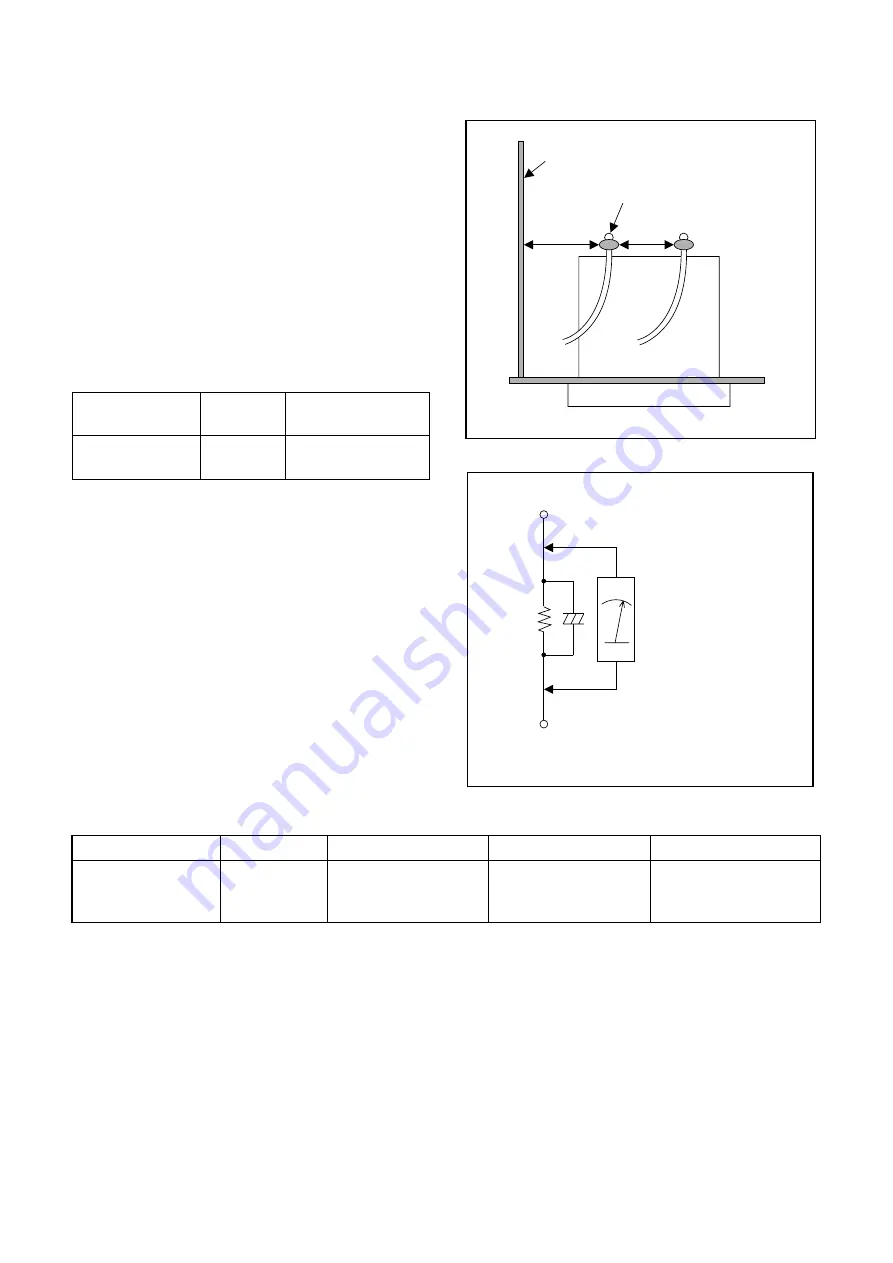

2. Leakage Current Test

Confirm the specified (or lower) leakage current be-

tween B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.).

Measuring Method : (Power ON)

Insert load Z between B (earth ground, power cord

plug prongs) and exposed accessible parts. Use an

AC voltmeter to measure across both terminals of

load Z. See Fig. 2 and following table.

Table 2 : Leakage current ratings for selected areas

Note:

This table is unofficial and for reference only. Be sure to confirm the precise values.

AC Line Voltage

Region

Clearance

Distance (d) (d')

110 to 130 V

USA or

CANADA

≥

3.2 mm

(0.126 inches)

Chassis or Secondary Conductor

d

d’

Primary Circuit Terminals

Fig. 1

Fig. 2

AC Voltmeter

(High Impedance)

Exposed Accessible Part

B

One side of

Power Cord Plug Prongs

Z

AC Line Voltage

Region

Load Z

Leakage Current (i)

Earth Ground (B) to:

110 to 130 V

USA or

CANADA

0.15

µ

F CAP. & 1.5k

Ω

RES. connected in

parallel

i

≤

0.5mA rms

Exposed accessible

parts