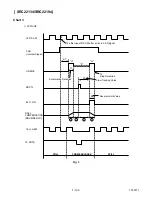

2-3-2

T5307MA

Adjust the X Value for maximum envelope.

(pg. 2-3-3) (Use Alignment Tape.)

Check to see that the tape is not creasing

and that there is no slack on the supply

and take-up side Guide Rollers.

(Use a blank tape.)

Adjust the height of the Guide Rollers

(Supply side and take-up side).

(Use a blank tape.) (pg. 2-3-3)

Loading (Use a blank tape.)

Adjust the envelope. (pg. 2-3-4)

Check the envelope.

Adjust the Audio Section.

(Azimuth Alignment) (pg. 2-3-4)

Check the audio output.

Check the following:

1. X Value (pg. 2-3-3)

2. Envelope (pg. 2-3-4)

Adjust the X value and envelope.

Not good

Do the final tape-traveling test to see that

the tape runs normally in play mode with-

out creasing or slacking.

Completion

Not good

OK

OK

OK

Not good

Not good

OK

Flowchart of Alignment for tape traveling

1-A

1-A

1-B

1-C

1-C

1-D

1-D

1-B, 1-C

1-B, 1-C

1-A

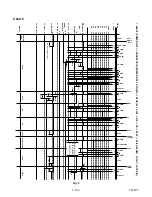

1.Tape Interchangeability Alignment

Note:

To do these alignment procedures, make sure that the

Tracking Control Circuit is set to the center position

every time a tape is loaded or unloaded. (Refer to

page 2-3-4, procedure 1-C, step 2.)

Equipment required:

Dual Trace Oscilloscope

VHS Alignment Tape (FL8N---[ SRC2213 ],

FL8NW---[ SRC22134/SRC22194 ])

Guide Roller Adj. Screwdriver

X-Value Adj. Screwdriver

Note: Before starting this Mechanical Alignment, do all

Electrical Adjustment procedures.

Summary of Contents for SRC2213

Page 20: ...1 6 2 T5307DC Fig 1 S 1 S 1 1 REAR CABINET S 1 S 1 S 1 S 1 Fig 2 ...

Page 22: ...1 6 4 T5307DC Fig 4 CRT CBA S 5 S 5 S 5 S 5 ANODE CAP 5 CRT ...

Page 25: ...1 6 7 T7308DC Fig 1 ANT S 1 S 1 1 REAR CABINET S 1 S 1 S 1 S 1 Fig 2 ...

Page 27: ...1 6 9 T7308DC Fig 4 S 5 S 5 S 5 S 5 5 CRT CRT CBA ANODE CAP ...

Page 89: ...Packing SRC22194 X 1 S 1 S 4 S 3 S 3 S 2 TAPE TAPE X 4 X 3 X 2 S 6 S 14 FRONT 3 1 6 T7308PEX ...

Page 108: ...Printed in Japan 2002 02 20 HO SRC2213 SRC22134 SRC22194 T5307UH 8UJ 7308UJ ...