1-3-2

SFTY_Z13N

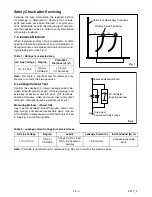

d. Preheating

Leadless capacitor must be preheated before

installation. (130°C~150°C, for about two minutes.)

1.2. Standard solder

a. Soldering Iron

Use a pencil-type soldering iron (less than 30

watts).

b. Solder

Eutectic solder (Tin 63%, Lead 37%) is recom-

mended.

c. Soldering time

Do not apply heat for more than 4 seconds.

d. Preheating

Leadless capacitor must be preheated before

installation. (130°C~150°C, for about two minutes.)

Notes:

a. Leadless components must not be reused after

removal.

b. Excessive mechanical stress and rubbing for the

component electrode must be avoided.

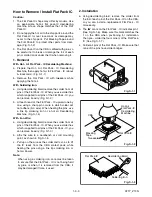

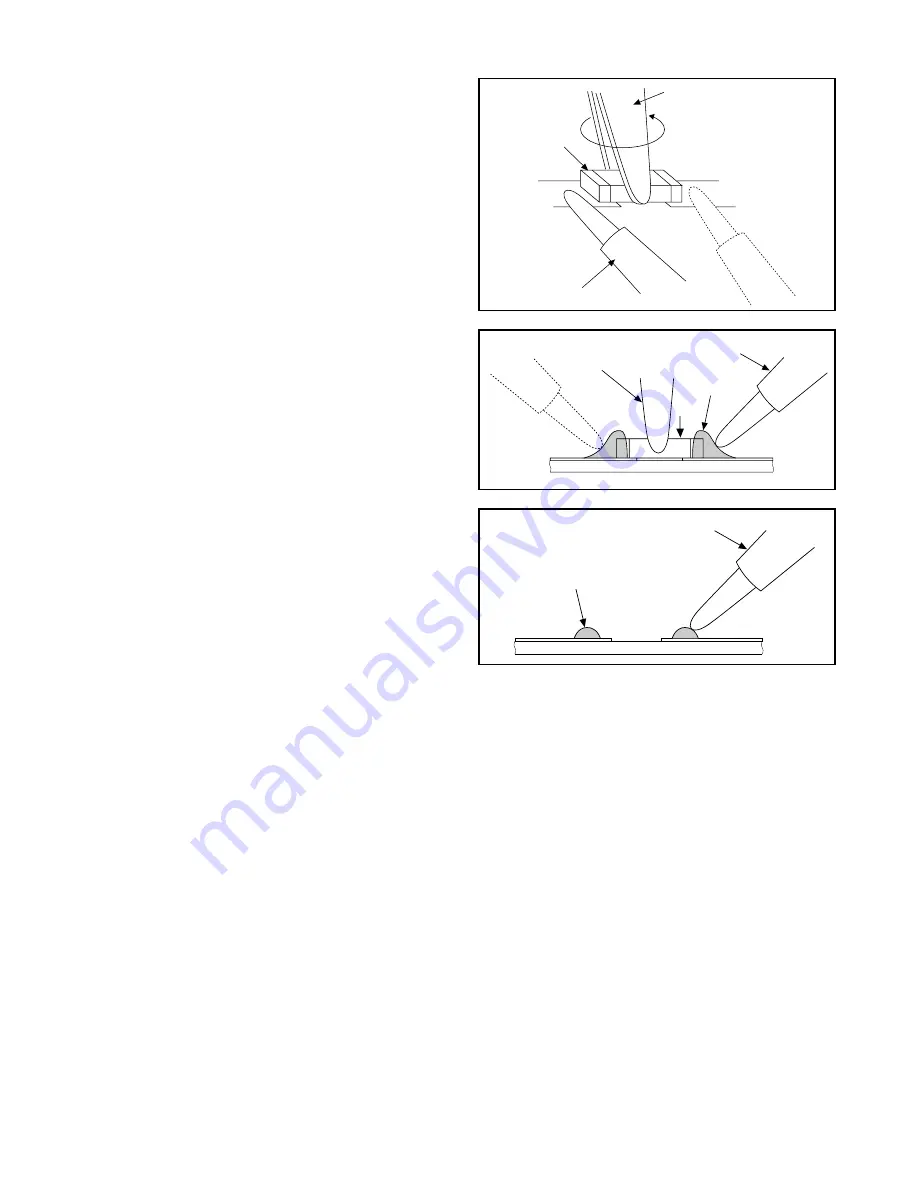

2. Removing the leadless component

Grasp the leadless component body with tweezers

and alternately apply heat to both electrodes. When

the solder on both electrodes has melted, remove

leadless component with a twisting motion.

Notes:

a. Do not attempt to lift the component off the board

until the component is completely disconnected

from the board by the twisting action.

b. Take care not to break the copper foil on the printed

board

3. Installing the leadless component

a. Presolder the contact points of the circuit board.

b. Press the part downward with tweezers and solder

both electrodes as shown below.

Note:

Do not glue the replacement leadless component to

the circuit board.

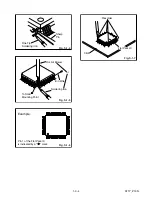

Chip

Tweezers

Soldering Iron

Soldering Iron

Tweezers

Solder

Soldering Iron

Presolder

Summary of Contents for SRC2213W

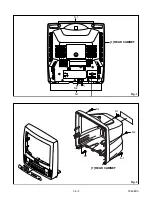

Page 17: ...1 5 2 T5505DC S 1 1 REAR CABINET S 1 S 2 Fig 1 Fig 2 1 REAR CABINET S 1 S 2 S 1 S 1 S 1 ...

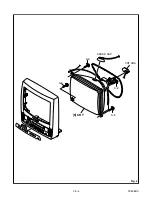

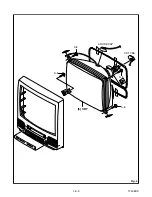

Page 19: ...1 5 4 T5505DC Fig 4 S 8 S 8 S 8 S 8 ANODE CAP 5 CRT CRT CBA ...

Page 24: ...1 5 9 T7505DC Fig 4 S 8 S 8 S 8 S 8 5 CRT CRT CBA ANODE CAP ...

Page 65: ...1 14 5 T5505PEX Packing SRC2213W X3 X4 X2 TAPE X1 X5 S2 S6 S3 S1 S4 FRONT ...

Page 66: ...1 14 6 T7505PEX SRC2419 X1 S1 S4 S3 S3 S2 TAPE TAPE X4 X3 X2 S6 S14 FRONT ...

Page 103: ...SRC2213W SRC2419 T5505UF T7505UF Printed in Japan 2004 03 20 HO ...