2-3-3

Z13N4HMA

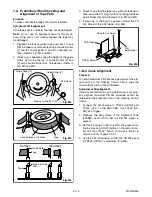

1-A. Preliminary/Final Checking and

Alignment of Tape Path

Purpose:

To make sure that the tape path is well stabilized.

Symptom of Misalignment:

If the tape path is unstable, the tape will be damaged.

Note:

Do not use an Alignment Tape for this proce-

dure. If the unit is not correctly aligned, the tape may

be damaged.

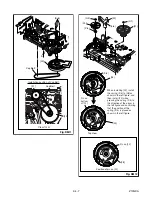

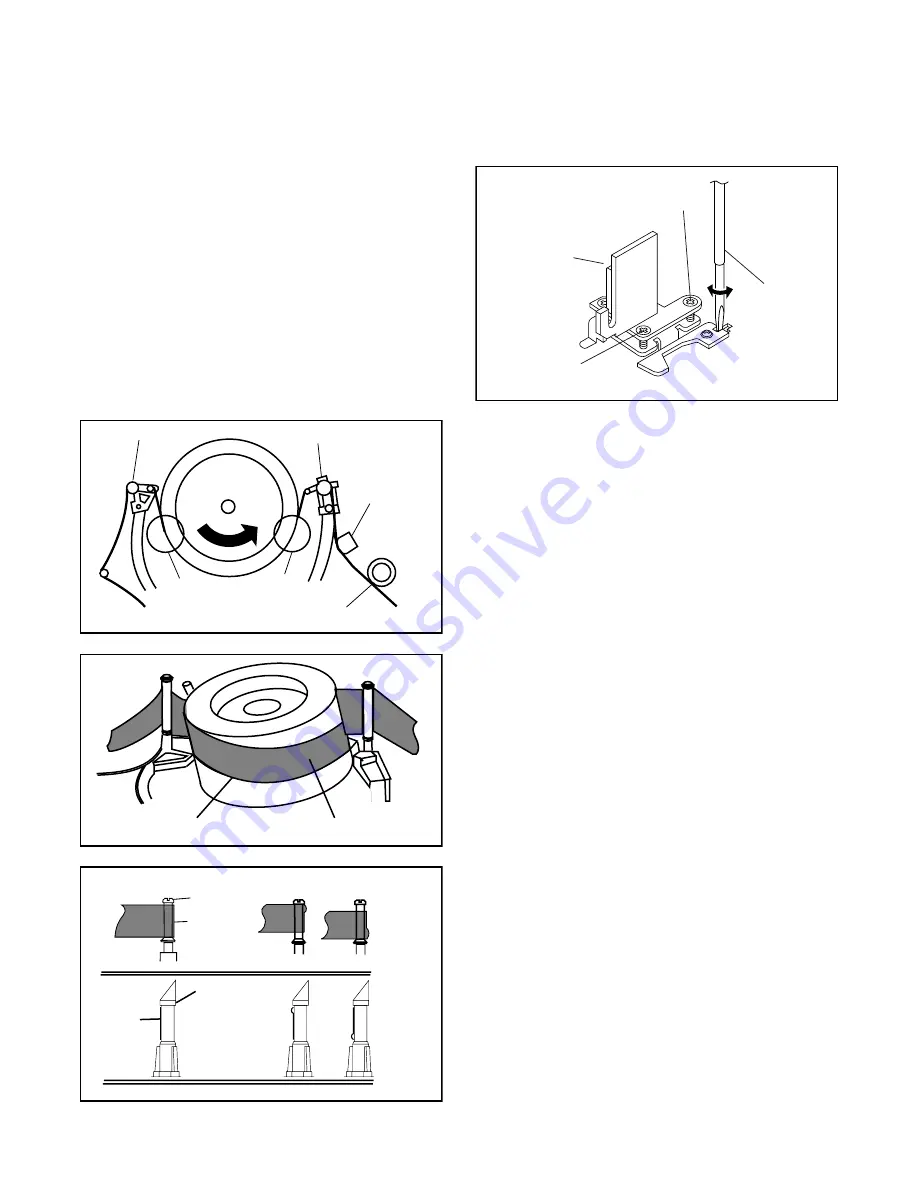

1. Playback a blank cassette tape and check to see

that the tape runs without creasing at Guide Rollers

[2] and [3], and at points A and B on the lead sur-

face. (Refer to Fig. M3 and M4.)

2. If creasing is apparent, align the height of the guide

rollers by turning the top of Guide Rollers [2] and

[3] with a Guide Roller Adj. Screwdriver. (Refer to

Fig. M3 and M5.)

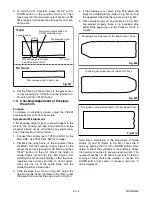

3. Check to see that the tape runs without creasing at

Take-up Guide Post [4] or without snaking between

Guide Roller [3] and ACE Head. (Fig. M3 and M5)

4. If creasing or snaking is apparent, adjust the Tilt

Adj. Screw of the ACE Head. (Fig. M6)

1-B. X Value Alignment

Purpose:

To obtain maximum PB FM envelope signal at the pre-

set position of the Tracking Control Circuit, align the

Horizontal Position of the ACE Head.

Symptom of Misalignment:

If the Horizontal Position of the ACE Head is not prop-

erly aligned, maximum PB FM envelope cannot be

obtained at the preset position of the Tracking Control

Circuit.

1. Connect the oscilloscope to TP402 (V-ENV) and

TP201 (CTL) on the Main CBA. Use TP202 (RF-

SW) as a trigger.

2. Playback the Gray Scale of the Alignment Tape

(FL8NW) and confirm that the PB FM signal is

present.

3. Set the Tracking Control Circuit to the preset posi-

tion by pressing CH UP button on the remote con-

trol unit then “PLAY” button on the unit. (Refer to

note on bottom of page 2-3-4.)

4. Use the Flat Screwdriver so that the PB FM signal

at TP402 (V-ENV) is maximum. (Fig. M6)

Guide Roller [2]

Guide Roller [3]

A

B

Take-up Guide Post [4]

ACE Head

Fig. M3

Lead Surface of Cylinder

Tape

Fig. M4

Fig. M5

Take-up Guide

Post

Tape

Guide Roller

Tape

Correct

Incorrect

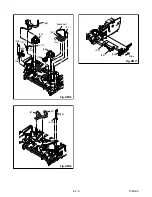

Fig. M6

Azimuth Adj. Screw

Flat

Screwdriver

Tilt Adj. Screw

ACE Head

Summary of Contents for SRC2213W

Page 17: ...1 5 2 T5505DC S 1 1 REAR CABINET S 1 S 2 Fig 1 Fig 2 1 REAR CABINET S 1 S 2 S 1 S 1 S 1 ...

Page 19: ...1 5 4 T5505DC Fig 4 S 8 S 8 S 8 S 8 ANODE CAP 5 CRT CRT CBA ...

Page 24: ...1 5 9 T7505DC Fig 4 S 8 S 8 S 8 S 8 5 CRT CRT CBA ANODE CAP ...

Page 65: ...1 14 5 T5505PEX Packing SRC2213W X3 X4 X2 TAPE X1 X5 S2 S6 S3 S1 S4 FRONT ...

Page 66: ...1 14 6 T7505PEX SRC2419 X1 S1 S4 S3 S3 S2 TAPE TAPE X4 X3 X2 S6 S14 FRONT ...

Page 103: ...SRC2213W SRC2419 T5505UF T7505UF Printed in Japan 2004 03 20 HO ...