11

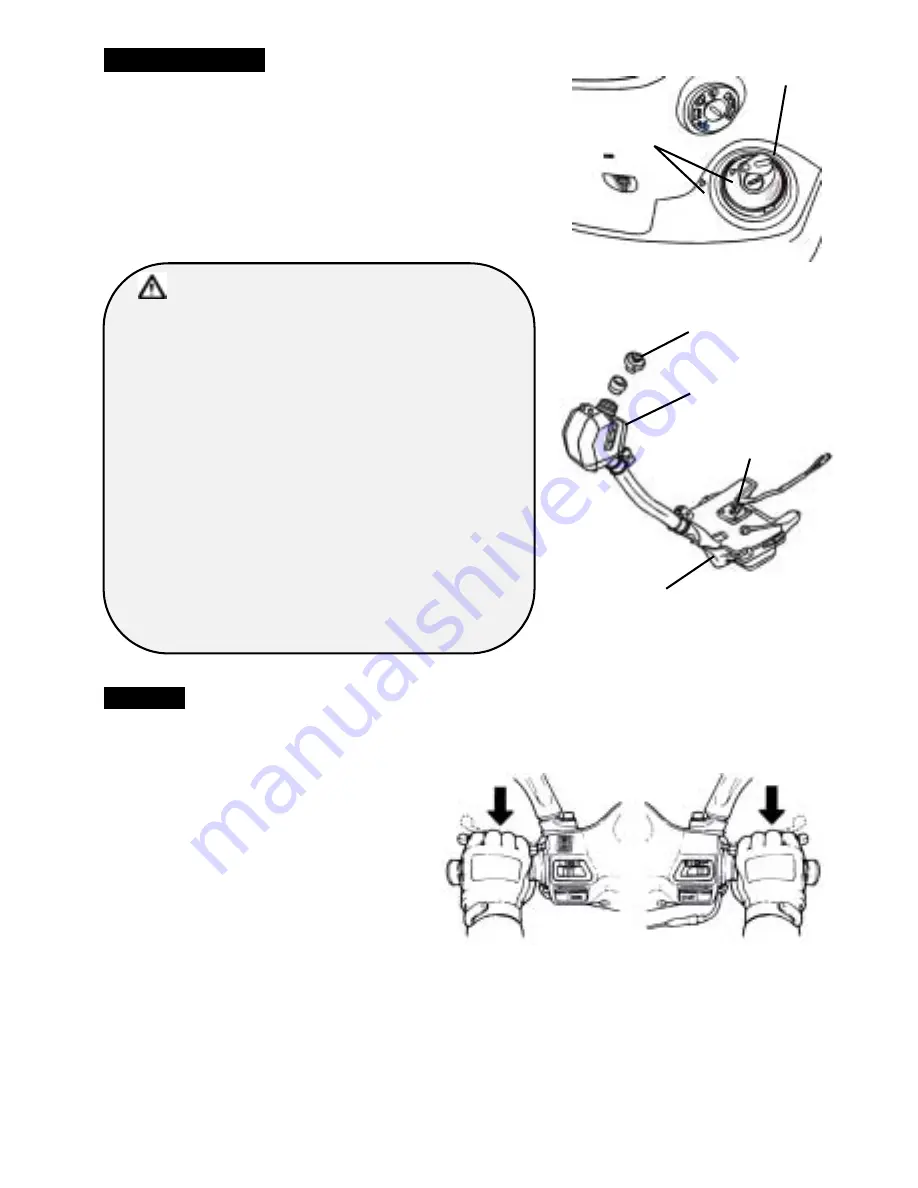

FUEL TANK CAP

【

Fuel refilling

】

1. Insert ignition switch key into the lock on the fuel tank

cap, and turn the key to the right, then the cap can be

removed.

2. Do not fill above the fuel upper limit when refueling.

3. Align the “

△

” mark on the cap with the “

△

” mark on

the body, and turn the key and the fuel cap right to lock

the fuel cap. To remove the ignition key, simply turn

the key to the left and then remove it.

BRAKE

Avoid unnecessary sudden braking.

Use front and rear wheel brakes

simultaneously when braking.

Avoid brake continuously for a long period

of time because that may overheat the

brakes and reduce its braking efficiency.

Slow down and brake early when riding in

rainy days on slippery roads. Never

apply the brakes suddenly to prevent

skidding and falling.

Using only the front brake or the rear

brake increases the risk of falling because

the motorcycle is tend to pulled to one

side.

《

Engine Brake

》

Return the throttle valve handle back to its original position, and apply engine brake.

It is necessary to apply both brake and engine brake intermittently when riding on a long or stiff slope.

CAUTION:

Main stand should be put down on the ground,

engine should be shut off and flames should be

strictly prohibited to ensure safety when refueling.

Do not fill above fuel upper limit when refueling.

Otherwise, fuel will flow out through a hole on the

cap that may damage the body’s painting, in

serious cases, it may cause a fire to burn down

the motorcycle.

Make sure the cap has been tighten properly.

This model has a reserve tank device. The fuel

indicator will not move before the fuel in the

reserve tank running out. After the fuel in the

reserve tank running out, it is normal that the

indicator drops down a little faster (fuel tank

capacity : 4 liter, sub tank capacity :1.5 liter).

For Rear Wheel

For Front Wheel

“△

”

mark

Fuel tank cap

Fuel tank cap

Sub fuel tank

Fuel tank

Fuel unit