4. FUEL SYSTEM SYM

4-8

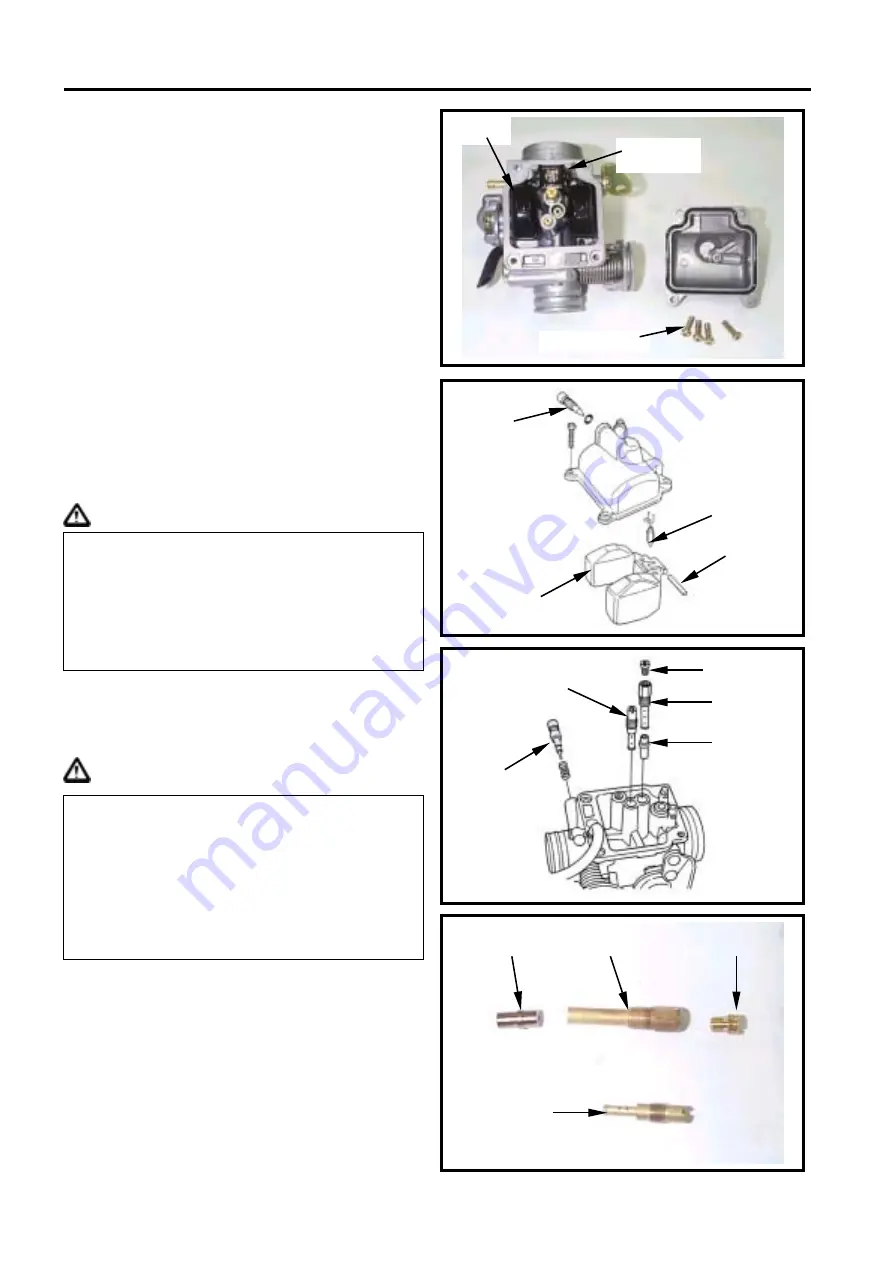

FLOAT CHAMBER

Disassembly

Remove 4 mounting screws and then the

float chamber cover.

Remove the float pin and float valve.

Checking

Check float needle valve and valve seat for

drop difference damage, wear out, dirty or

clogged.

Cautions

Remove main jet, fuel needle jet holder, fuel

needle jet, slow jet, fuel amount adjustment

screw.

Cautions

Clean jets with cleaning fluid.

Then use compressed air to blow dirt off.

Blow carburetor body passages with

compressed air.

In case of worn out or dirt, the float valve

and valve seat will not tightly close

causing fuel level to increase and as a

result, fuel flooding. A worn out or dirty

float valve must be replaced with a new a

new one.

Take care not to damage jets and adjust

screw.

Before removing adjustment screw, turn

it all the way down and note the number

of turns.

Do not turn adjustment screw forcefully

to avoid damaging valve seat face.

screws

×

4

float

float pin

main jet

fuel needle jet

fuel needle holder

slow jet

float

float pin

float needle

valve

float pin

main jet

slow jet

fuel needle

jet

fuel needle

holder

fuel am

ount

adjustmen

t screw

Summary of Contents for ALA125CC

Page 45: ...SYM 13 BRAKE 13 3 MECHANISM DIAGRAM Rear Drum Brake System 0 8 1 2 kgf m 0 8 1 2 kgf m...

Page 93: ......

Page 176: ...SERVICE MANUAL...