7. CYLINDER/PISTON SYM

7-2

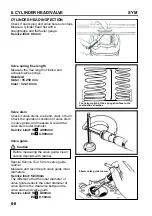

PRECAUTIONS IN OPERATION

General Information

Both cylinder and piston service cannot be carried out when engine mounted on frame.

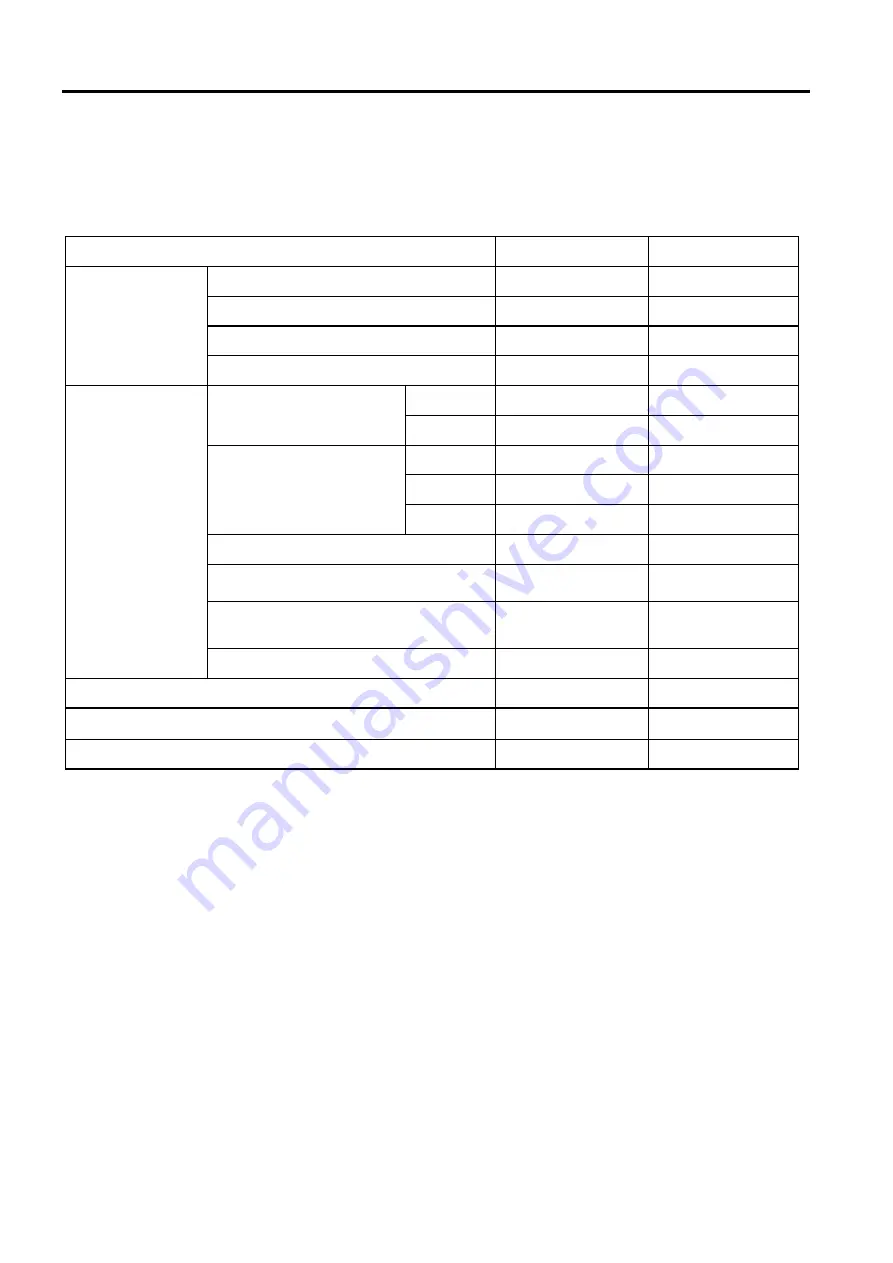

Specification unit:

mm

Item Standard

Limit

ID 58.50

58.2~58.5

Bend/wrap age

-

0.050

Roundness 0.005

0.050

Cylinder

Cylindrical 0.005

0.050

Top ring

0.025~0.060

0.090

Clearance between

piston rings

2

nd

ring

0.015~0.050

0.090

Top ring

0.200~0.400

0.500

2

nd

ring

0.250~0.400

0.650

Ring-end gap

Oil ring

0.200~0.700

-

OD of piston

52.370~52.390

52.300

Piston OD measurement position

Lower-end up 7mm

of piston skirt

-

Clearance between piston and

cylinder

0.010~0.040 0.100

Piston/

Piston ring

ID of piston pin hole

15.002~15.008

15.040

OD of piston pin

14.994~15.000

14.980

Clearance between piston and piston pin

0.002~0.014

0.060

ID of connecting rod small-end 15.005~15.020

15.060

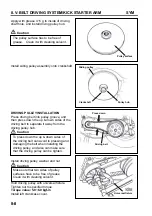

TROUBLE DIAGNOSIS

Low Or Unstable Compression Pressure

Cylinder or piston ring worn out.

Compress pressure to high.

Too much carbon deposited in combustion

chamber and piston.

Knock or Noise

Cylinder or piston ring worn out.

Carbon deposits on cylinder head top-side.

Piston pin hole and piston pin wear out.

Smoking in Exhaust Pipe

Piston or piston ring worn out.

Piston ring installation improperly.

Cylinder or piston damage.

Engine Overheat

Carbon deposits on cylinder head top side.

Summary of Contents for ALA125CC

Page 45: ...SYM 13 BRAKE 13 3 MECHANISM DIAGRAM Rear Drum Brake System 0 8 1 2 kgf m 0 8 1 2 kgf m...

Page 93: ......

Page 176: ...SERVICE MANUAL...