SYM 16. ELECTRICAL EQUIPMENT

16-5

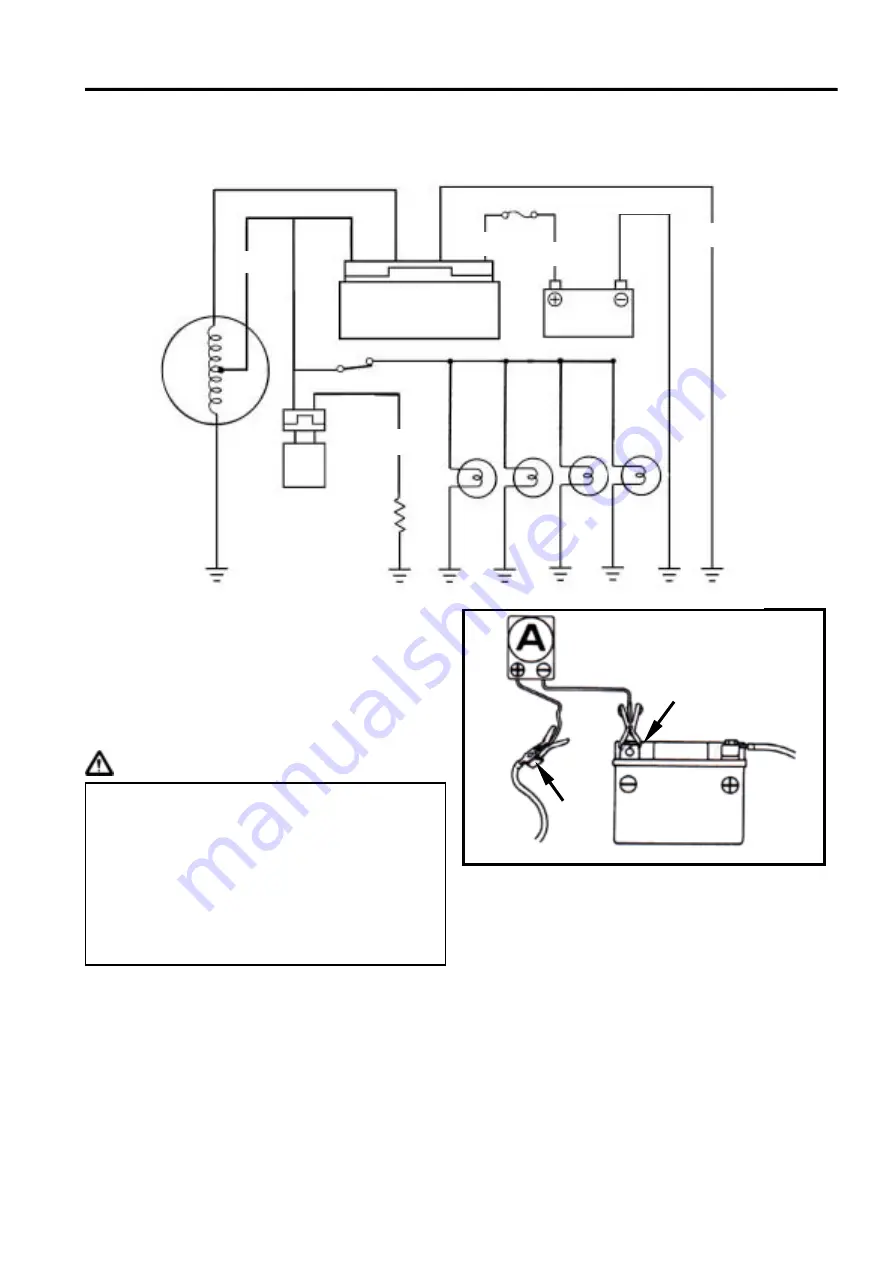

CHARGING SYSTEM

Charging wire diagram

Current Leakage Inspection

Turn the main switch to OFF position, and

remove the negative cable terminal (-) from

the battery.

Connect an ammeter between the negative

cable terminal and the battery negative

terminal (as shown on left diagram).

Caution

If the leaked current exceeds the specified value,

it may indicate a short circuit.

Allowable current leakage: Less than 1 mA.

Disconnect each cable one by one and take

measurement of the current of each cable to

locate the short circuit.

In the current leakage test, set the

current range at larger scale, then

gradually decrease to the lower scale

as the test process goes to avoid

possible damage to the ammeter and

the fuse.

Do not turn the main switch to “ON”

position during test.

Battery(-) terminal

ground

wire

alternator

Auto

by-starter

REG.REC.

fuse(7A

)

Battery

12V 6AH

green

yellow

white

red

5

W

5

Ω

green/black

green

red

green

Summary of Contents for ALA125CC

Page 45: ...SYM 13 BRAKE 13 3 MECHANISM DIAGRAM Rear Drum Brake System 0 8 1 2 kgf m 0 8 1 2 kgf m...

Page 93: ......

Page 176: ...SERVICE MANUAL...