4. FUEL SYSTEM SYM

4-10

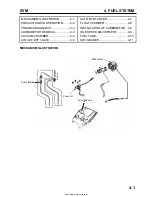

FUEL TANK

Fuel unit removal

Open the seat.

Remove the luggage box. (6 bolts)

Remove the engine starter control switch

wire connector .

Disconnect fuel unit connector.

Remove fuel unit.

Cautions

Fuel unit inspection. (Refer to chapter 16 -

electrical equipment).

Fuel unit installation

Install the gauge in the reverse order of

removal.

Cautions

FUEL TANK REMOVAL

Open the seat.

Remove the luggage box assembly (6 bolts).

Disconnect the engine start control switch

connector.

Disconnect the fuel unit connector.

Remove the fuel pipe, fuel filter.

Remove the fuel tank (2 bolts).

Fuel Tank Installation

Install the tank in the reverse order of

removal.

Do not bend the float arm of fuel unit.

Do not fill out too much gasoline to

fuel tank.

Do not forget to install the gasket of fuel unit

or damage it.

fuel unit

gasket

Fuel unit connector

http://www.motorcycle.in.th