8

QSG Diode Pointer Ver 2.1

a Novanta company

Diode Pointer Quick Start Guide

15.

Repeat the near and far field adjustments steps mentioned previously.

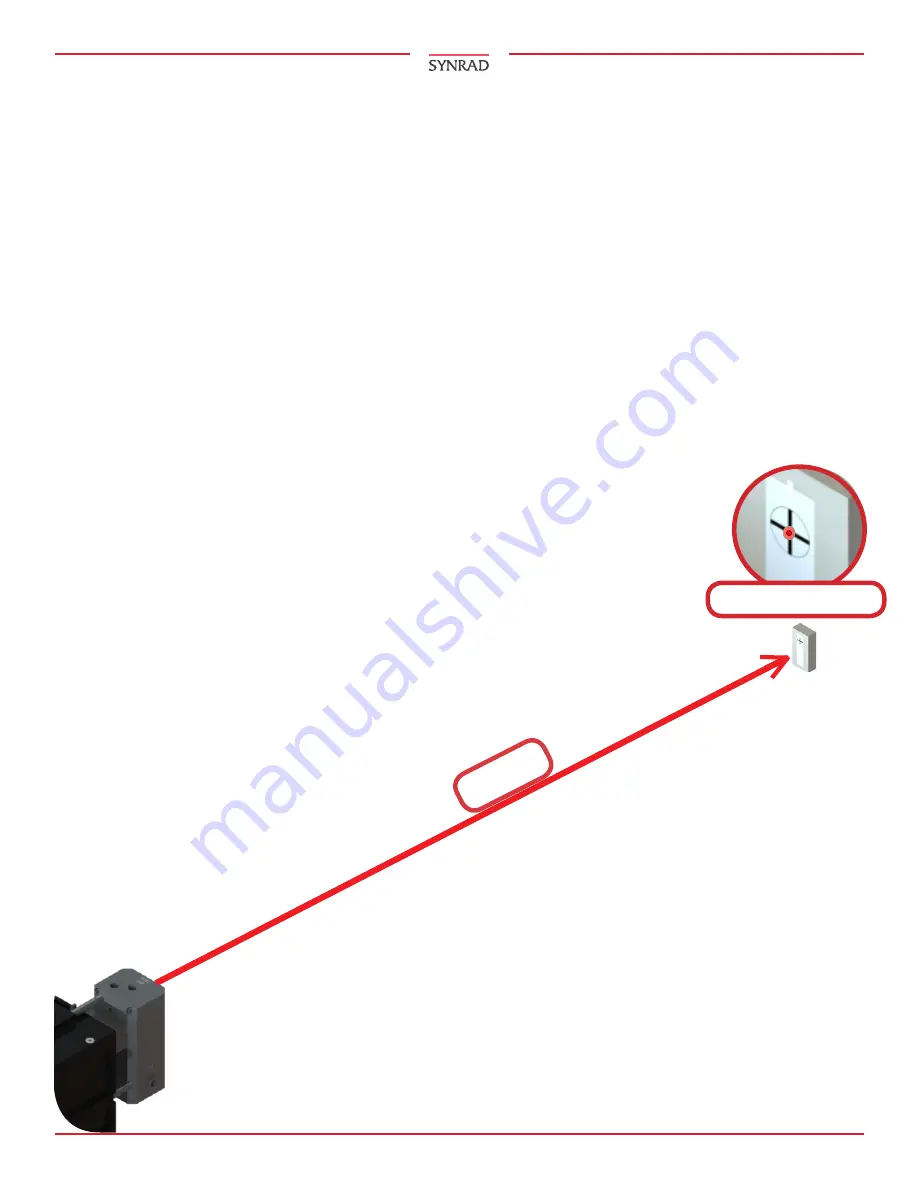

The goal of the adjustment procedure is to get the CO

2

beam and the Diode Pointer coincident within 100

microradians, which is equivalent to 1 mm at 10 meters of misalignment as the recommended outside tol-

erance of alignment. Anything more precise and accurate is desirable, but not necessary. Final accuracy and

precision alignment is completely dependent on the final use of the pointer. Most articulated arm applica-

tions require 100 micro-radians, while a simple lens system requires only 1 milliradian. The outside tolerance

or acceptable misalignment is 1 milliradian, or 1 mm at 1 meter.

Congratulations!

The Diode Pointer is now correctly installed and the rest of the beam delivery system can now be installed.

Coarse Adjustment (Continued):

10 M

1 mm at 10 meters.