operation

2

5

Synrad

Firestar i401

operator’s manual

Initial start-up

Important Note:

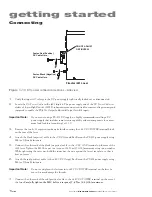

To initiate lasing, apply a voltage in the range of ±5–24 VDC to the

Remote Inter-

(continued)

lock

input. This causes the

INT

LED to turn green, the

RDY

indicator to turn yel-

low, and sends DC power to the laser’s RF boards, allowing internal tickle pulses to

reach the tube. Apply a

Shutter Open Request

signal (a voltage in the range of

±5–24 VDC) to open the physical shutter assembly and then apply a PWM Com-

mand signal to begin lasing.

Removing the

Shutter Open Request

signal causes the shutter to close and block

the beam path while simultaneously disabling the PWM input signal, leaving the

internal tickle generator enabled to supply tickle signals as required to maintain tube

readiness.

With a UC-2000 Controller

Before your Firestar

®

i401 laser is put into service for the first time, its functionality should be verified. Fol-

low this procedure to verify the laser system is operating at optimum performance. For this procedure, use

the UC-2000 as a stand-alone controller; do not attempt to control the laser or UC-2000 externally.

Note:

When performing the initial start-up sequence, you must first connect the

Quick Start Plug

or you

must provide the required

Remote Interlock

and

Shutter Open Request

signals to the

User I/O

connector. See

User I/O connections

in the Technical Reference chapter for

User I/O

pinouts and

signal descriptions.

Starting auxiliary equipment

1

Ensure that all personnel in the area are wearing protective eyewear.

2

Place a beam block 0.5 meters (20 in.) inches from the laser aperture to prevent the beam from trav-

eling beyond the work area.

Caution

possible

equipment

damage

Inlet cooling water temperature must always be maintained above the

dew point to prevent condensation and water damage to your Firestar

laser.

Caution

possible

equipment

damage

Do not exceed a gas purge pressure of 5 PSI (0.34 Bars). Excessive

pressure may damage the purge assembly or other internal laser com-

ponents.

Do not use argon as a purge gas. Use only nitrogen or clean, dry air as

described in Table 1-3,

Purge gas specifications

.

3

Turn on the chiller and set the temperature setpoint between 18 °C–22 °C. Verify that the chiller

is delivering a flow rate of 4 GPM at less than 60 PSI of pressure. Examine all cooling connections

carefully and ensure that they do not leak.