operation

2

8

Synrad

Firestar i401

operator’s manual

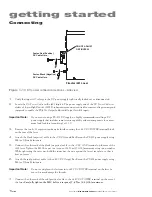

Initial start-up

3

Turn on the chiller and set the temperature setpoint between 18 °C–22 °C. Verify that the chiller

is delivering a flow rate of 4 GPM at less than 60 PSI of pressure. Examine all cooling connections

carefully and ensure that they do not leak.

Warning

serious

personal

injury

Because of phase differences, external tickle pulses may combine

with the internally-generated tickle signal causing the

LASE

LED to

flicker during the transition from tickle to lasing. Laser output may

occur if the

LASE

LED flickers.

Caution

possible

equipment

damage

Do not exceed a gas purge pressure of 5 PSI (0.34 Bars). Excessive

pressure may damage the purge assembly or other internal laser com-

ponents.

Do not use argon as a purge gas. Use only nitrogen or clean, dry air as

described in Table 1-3,

Purge gas specifications

.

4

Start purge gas flow at a rate of 30–60 Standard Cubic Feet per Hour (SCFH) at a pressure not

to exceed 5 PSI (0.34 Bars) If a flowmeter is not available, set a purge pressure between 2–5 PSI

(0.14–0.34 Bars).

5

Ensure that your PWM controller is set to zero percent output (0.0%).

6

Turn on the +48 VDC power supply.

If the factory-wired

Quick Start Plug

is installed, the

INT

indicator will illuminate green, the

SHT

indicator will illuminate blue, and the

RDY

LED will illuminate yellow. The

TMP

indicator will il-

luminate green if laser temperature is within safe operating limits.

Starting your Firestar i401 laser

Important Note:

Unlike other Firestar lasers, the

SHT

LED on i401 lasers is dependent on the state

of the

RDY

indicator. Although a

Shutter Open Request

signal is applied, the

SHT

LED will not light while the

RDY

LED is Off. Therefore, no power is applied to the

RF boards until the

RDY

indicator is illuminated.

Important Note:

Each time an i401 OEM laser is powered up, a five-second delay occurs between the

time the

RDY

indicator illuminates and the i401 is permitted to lase. After the five-

second delay (and while the

SHT

LED is off), tickle is applied to maintain the laser

in a ready state. Once a

Shutter Open Request

signal is applied, and the

SHT

LED

illuminates, apply PWM Command signals to begin lasing.

1

Apply a PWM Command signal (+5 VDC, 5 kHz square wave of 4 µs duration) between

PWM Input

(Pin 9) and

PWM Return

(Pin 1) on Firestar’s

User I/O

connector.