technical reference

3

3

Synrad

Firestar i401

operator’s manual

Technical overview

0

1

2

3

4

5

6

7

8

9

10

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

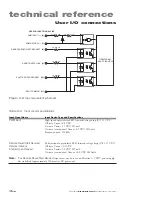

Ellipticity

Distance From Front Plate in Meters

Ellipticit

y

2

0

widthY( )

z

ωx( )

z

1

10

0

z 2.6

0

10

20

30

40

50

60

70

80

90

100

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

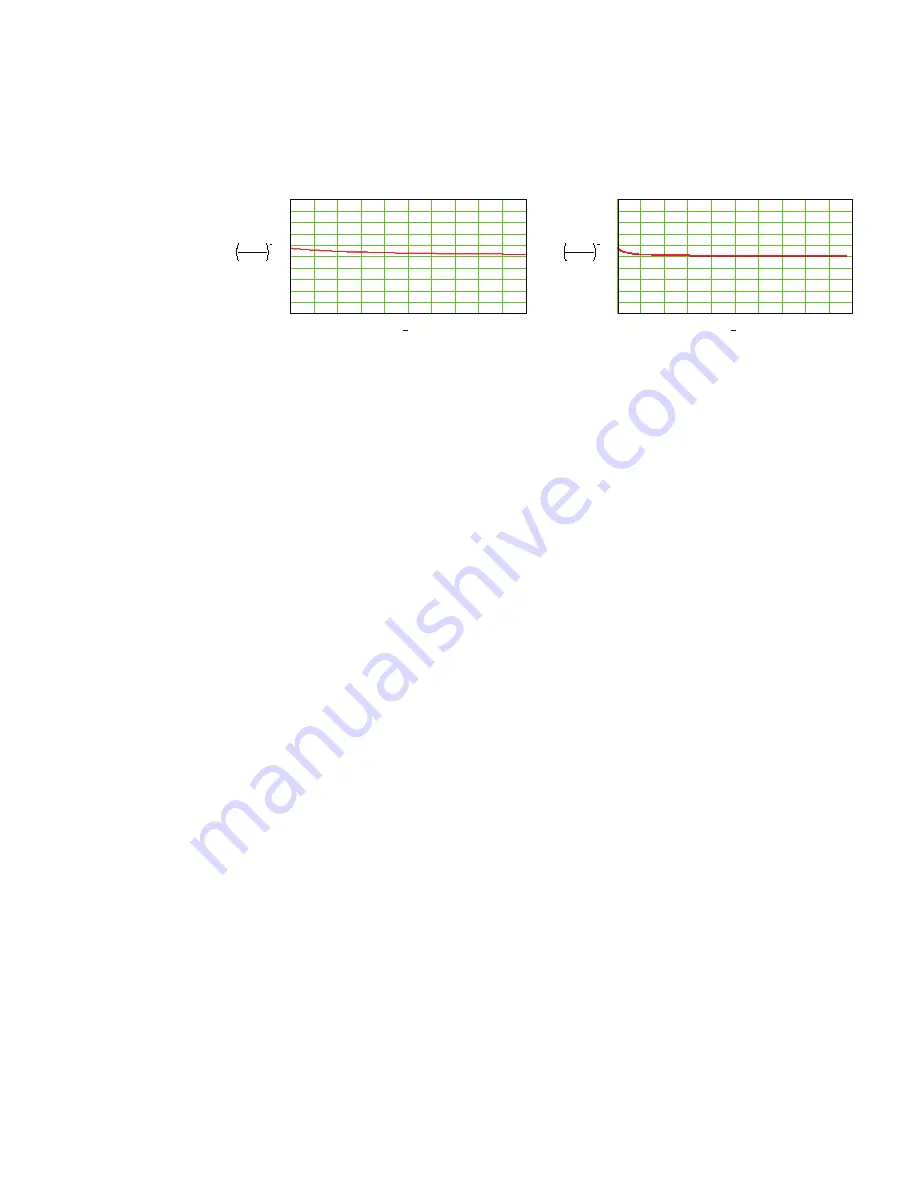

Ellipticity

Distance From Front Plate in Meters

Ellipticit

y

2

0

widthY( )

z

ωx( )

z

1

100

0

z 2.6

Figure 3-2

Firestar i401 beam ellipticity

Heat removal

Heat generated by excited CO

2

molecules is transferred to the bore walls by diffusion. Collected heat is

transferred to the water in the cooling tubes by conduction of the electrodes and aluminum envelope. The

coolant path is directed through corrosion-resistant copper alloy tubing to regulate laser temperature for

maximum stability.

Beam conditioning

The i401 laser incorporates a novel beam conditioning system that first converts the beam to a circular

profile, cleans up the beam to remove side lobes and improve beam quality, and then rotates the polariza-

tion through 45 degrees as an aid in applications where a circular polarizer is used. To do this, the laser

beam exits the resonator and is turned back on itself through a front folding block that directs the beam

into a cylindrical lens located about 25 inches (0.63 m) away from the resonator output. The cylindrical

lens converts the beam into a round beam which is then focused by a spherical focusing mirror through a

water-cooled aperture (to remove any side lobes) and then onto another spherical mirror that collimates

the beam. This beam then passes the shutter mechanism and through the rear folding mirror/beam rotator

assembly which rotates the beam 45 degrees before exiting through the output aperture.

Polarization

Polarization is important in achieving the best cut quality from a laser and this is usually

achieved with linear polarization aligned with the cut direction; however, in most applications

where two axes of cut are required, linearly polarized light can lead to differences in cut quality

depending on the orientation of the polarization with respect to the cutting direction.

Converting the laser polarization from linear to circularly polarized light gives uniform cut

quality in both axes. Circularly polarized light can be generated without significant power loss

by using a circular polarizer (also known as a cut quality enhancer or CQE) or a simple phase

retarding mirror.

For the simplest and most cost-effective solution, a reflective phase retarder, laser polarization

must be rotated by 45°. Because most lasers have horizontally or vertically polarized outputs

with the cutting or welding substrate placed horizontally, this rotation of the polarization is

usually done by mounting the laser at 45° to the horizontal or by using two or more mirrors.

Mounting the laser at 45° is often not practical while the addition of extra mirrors in the beam

path adds cost and complexity and can reduce reliability.