technical reference

3

8

Synrad

Firestar i401

operator’s manual

Controlling laser power

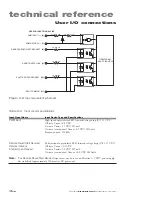

Table 3-2

PWM Command signal specifications

Laser State

Minimum

Nominal

Maximum

Laser Off

0.0 VDC

0.0 VDC

+0.8 VDC

Laser On

+3.5 VDC (3 mA)

+5.0 VDC

+6.7 VDC (10 mA), continuous

Frequency Range

0 Hz (DC)

5 kHz

100 kHz

Duty Cycle

0%

— —

100%

Operating modes

External control

In addition to controlling the Firestar i401 laser using a UC-2000 Controller, control of the i401 exter-

nally, without a UC-2000, is also possible. The two primary elements of laser control are gating, the ability

to turn the laser on and off at the appropriate times, and power, the ability to control the laser’s output

energy. Both gating and power can be handled by a device such as a personal computer, Programmable

Logic Controller (PLC), or function generator capable of sending PWM pulses at the proper time (gating)

and with the proper duty cycle (power).

Analog voltage or current control

Although Firestar i401 lasers cannot be controlled directly by analog voltage or current signals, this type of

control is possible when using the UC-2000 Controller. The Controller is connected normally to the laser

and analog voltage or current signals sent to the UC-2000’s

ANV/C

connector then control both laser

gating and power.

To generate the correct analog voltage from a computer or PLC, a Digital-to-Analog (D/A or DAC) card

capable of generating 0 V (laser off) to 10 V (maximum laser power) must be installed. To generate the

proper analog current, install a D/A card that can generate 4 mA (laser off) to 20 mA (maximum power).

Software able to control your analog output card is required for either configuration.

Continuous wave (CW)

In some applications, such as high speed marking or cutting, the time constant of the laser and the PWM

modulation causes a series of dots that may be visible on the marking surface instead of a “clean” line.

Operating the laser in CW mode will prevent this behavior from occurring.

To operate the laser in CW mode, apply a co5 VDC signal to Pin 9,

PWM Input

, and Pin 1,

PWM

Return

, on the

User I/O

connector. This constant voltage source forces the internal switching electronics

to remain on, providing continuous and uninterrupted laser output power. During CW operation, output

power cannot be changed. To adjust output power, refer back to the

Pulse Width Modulation (PWM)

sec-

tion for information regarding high frequency operation.

Note:

SYNRAD lasers are designed for maximum performance using a 95% duty cycle. Increasing the

maximum PWM percentage beyond 95% greatly increases the laser’s heat load with little or no

corresponding increase in laser output power. Continuous operation at 99% duty cycle may lead

to thermal instability and optical degradation.