technical reference

3

11

Synrad

Firestar i401

operator’s manual

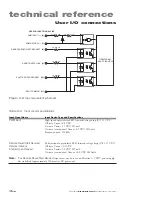

User I/O connections

User I/O connection summary

Table 3-3 below provides a quick reference summary to Firestar i401

User I/O

connections.

Table 3-3

User I/O pin descriptions

Pin Function

Description

1

PWM Return

Use this input pin as the return side of the PWM Command signal.

2

Remote Reset/Start Request input

Apply a positive or negative voltage (±5–24 VDC) with respect to Pin 11,

Input Common

,

to reset or remote keyswitch the laser. The laser remains disabled while voltage is applied.

Removing voltage from the

Remote Reset/Start Request

input causes the laser’s

RDY

indicator to illuminate and begins a five-second countdown after which lasing is enabled.

3

Remote Interlock input

Apply a positive or negative voltage (±5–24 VDC) with respect to Pin 11,

Input Common

,

to enable lasing. If your system does not use a remote interlock, this pin must be connected

to a voltage source in the range of ±5–24 VDC. Refer to Figure 3-7 for a diagram showing

how the

Remote Interlock

input is factory-jumpered.

4

+ 5 VDC Auxiliary Power

This connection pr5 VDC for driving external inputs or outputs. The

+5 VDC

Auxiliary Power

output can source up to 0.5 A and is protected by a 0.5 A self-resetting

fuse. The return (ground) path must be through Pin 12,

Auxiliary DC Power Ground

.

5

+ 24 VDC Auxiliary Power

This connection pr24 VDC for driving external inputs or outputs. The

+24 VDC

Auxiliary Power

output can source up to 0.5 A and is protected by a 0.5 A self-resetting

fuse. The return (ground) path must be through Pin 12,

Auxiliary DC Power Ground

.

6

Laser Active output

This bi-directional switched output is internally connected to Pin 13,

Output Common

,

when the laser is actively lasing (

LASE

indicator illuminated red). This output is open

(high impedance) when no beam is being emitted (

LASE

indicator Off).

7

Fault Detected output

This bi-directional switched output is internally connected to Pin 13,

Output Common

,

when (1) laser temperature is above safe operating limits (

TMP

LED illuminated red) or

(2) a No-Strike condition has occurred (blue

SHT

indicator is flashing). The output is open

(high impedance) when laser operation is within limits (

TMP

LED green and

SHT

LED

blue).

8

Laser Ready output

This bi-directional switched output is internally connected to Pin 13,

Output Common

,

when the laser is enabled (

RDY

LED illuminated yellow), indicating that lasing will occur

when a PWM Command signal is applied to Pin 9 and Pin 1. When this output is initially

switched closed, there is a five-second delay during which lasing is inhibited. This output is

open (high impedance) when the laser is disabled (

RDY

indicator Off).