2

CAUTION: To prevent possible damage, lift the jogger by the base only. Lifting by the bin or top cover

may cause damage.

Locate the jogger on a solid support. The support must not vibrate while the jogger is operating. The bin or top

cover must not be in contact with any rigid object or adjacent surface; it must be free to vibrate.

OPERATION

Place the jogger in its operating location and plug it into a self-grounding electrical receptacle. The power

supply voltage and frequency must be as specified on the nameplate.

The vibratory amplitude of the unit is changed by a rheostat located on the control. Various deck configurations

are available. See Syntron Material Handling, LLC. Syntron product literature for further details, capacities, etc.

For maximum efficiency, Syntron Material Handling, LLC. recommends a maximum load of 10 pounds for the

J-1-D Jogger.

MAINTENANCE

Adjusting the Air Gap

WARNING: The air gap must be adjusted while the jogger is in operation. Exercise caution to pre- vent

electrical shock to personnel or damage to the jogger. A striking condition (indicated by a loud rapping noise) is

caused by "too close" of an air gap. An excessive current draw (indicated by excessive heat) is caused by "too

wide" of an air gap.

Caution: Do not operate the jogger when either condition exists. An adjustment of the air gap is required.

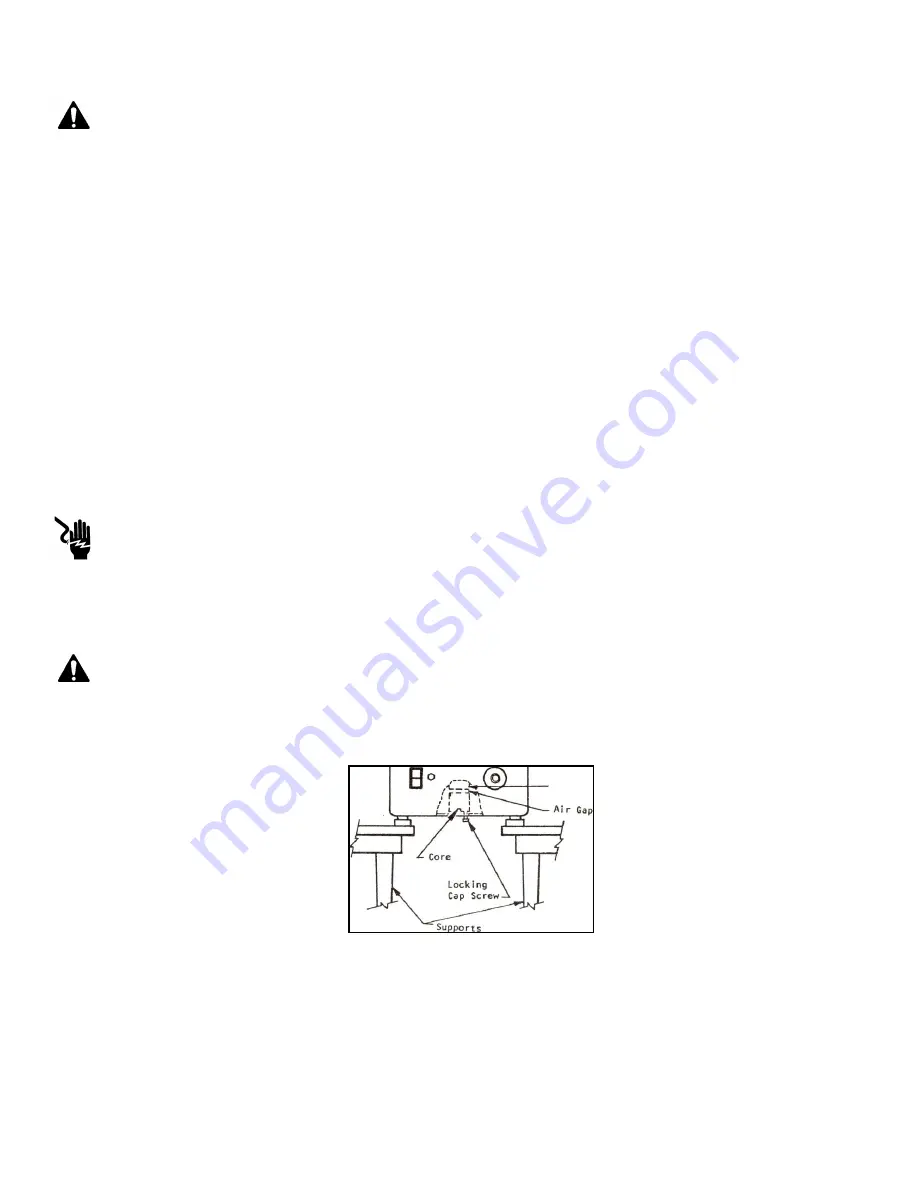

Place the jogger in a position to gain access to the adjustment screw on the bottom. As suggested in Figure 1,

place the jogger between two tables. Supporting the jogger by the bin or cover, or hand-holding the jogger will

affect the adjustment of the air gap. The unit must be supported at the rubber feet.

Armature

Fig. 1 - Air Gap Adjustment

Plug the electrical cord into a receptacle and operate the jogger at "100" dial setting. On the bottom of the

jogger, loosen the socket head cap screw, which locks the core in position. Adjust the air gap using a

screwdriver in the slot adjacent to the locking cap screw.

Note: Turning the screwdriver clockwise will lessen the air gap (to lessen the current draw). Turning the