Protouch-wide: user documentation

DOC/PROTOUCH-WIDE-R; V1.1

DOC_PROTOUCH_WIDE-R_V1.0.docx

Seite 31 von 41

© 2018 Syslogic Datentechnik AG | All rights reserved

3.2.5

Cabling of communication links

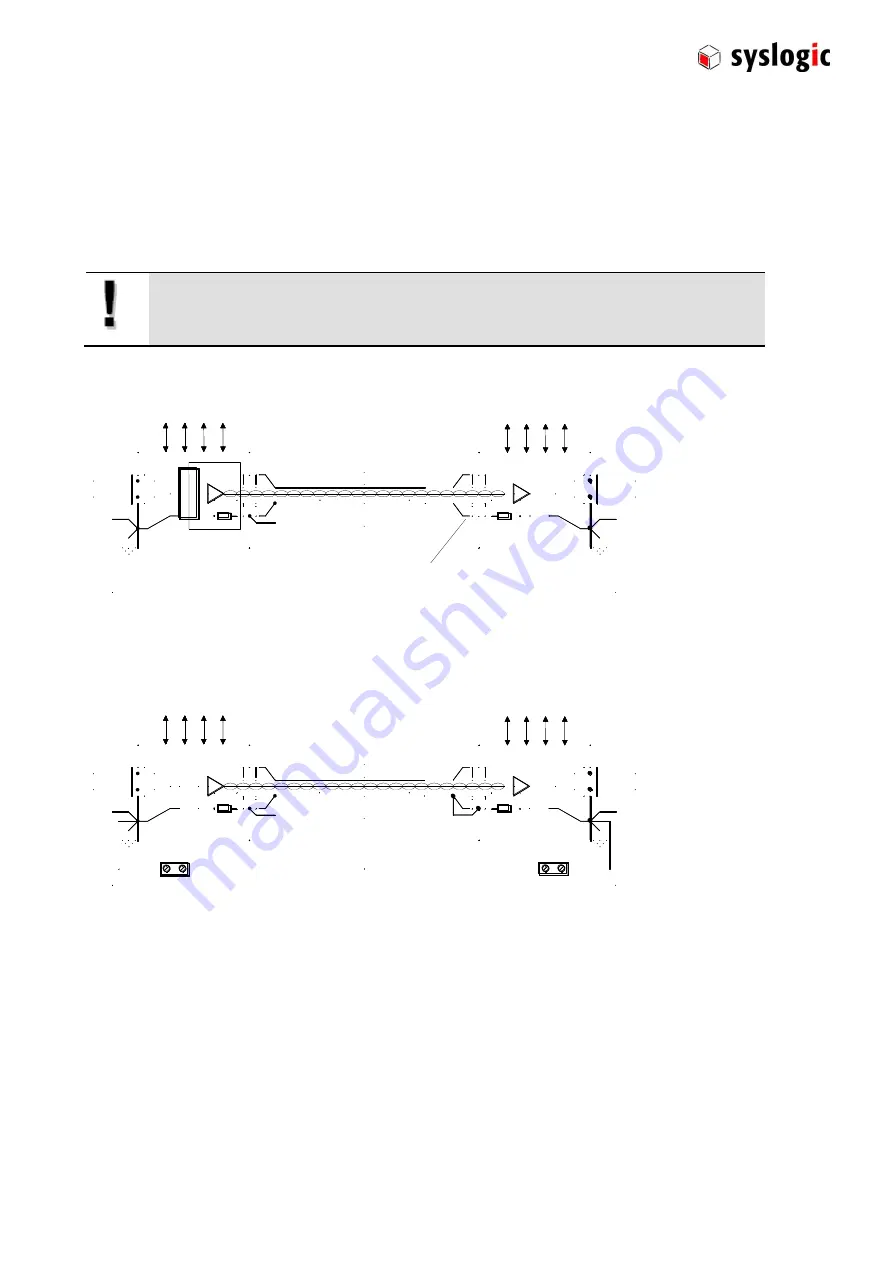

If the communication ports are non-isolated ports, cable shields have to be connected to chassis potential on both sides of the interconnection

cable. If the cable is very long, a thick copper wire (10 mm

2

) for potential adjustment is highly recommended. Fig. 15 shows a non-isolated

system with common chassis ground.

Some of the communication ports are galvanically isolated ports. In such cases the shield of the interconnection cable must be wired to chassis

potential only on one side of the cable. Fig. 14 shows an isolated system with independent grounds.

Important

Note

Grounding of the cable’s shields using

pig-tail wires

is not recommended because of their high

impedance at high frequencies. It is better to clamp the shields onto a grounded copper rail.

Fig. 14

Isolated communication link

Fig. 15

Non-isolated communication link with common chassis potential

Unisolated Node

24 VDC

24 VDC

0 VDC

0 VDC

100E

100E

Zentraler Erdpunkt am Chassis

Central Grounding Point

Zentraler Erdpunkt am Chassis

Central Grounding Point

I/O

Communication Link

Abschirmung/Shield

Unisolated Node

IPC System Nr. 1

IPC System Nr. 2

Potential-Ausgleichsleitung min. 10 mm

2

Kupfer

Copper-wire for Potential Adjustment, min. 10 mm

2

I/O

Isolated Node

24 VDC

24 VDC

0 VDC

0 VDC

100E

100E

Opto

Zentraler Erdpunkt am Chassis

Central Grounding Point

Zentraler Erdpunkt am Chassis

Central Grounding Point

I/O

Communication Link

Abschirmung/Shield

Achtung: keine Verbindung

des Kabelmantels mit dem Chassis

Do not connect cable-shield with

chassis, floating operation

Unisolated Node

IPC System Nr. 1

IPC System Nr. 2

I/O