- 18 -

699-41-20.1

Screw out the cylinder-head screws (1) of the pull-back cap (4). If

a contact flange for inductive proximity switches is attached to the

carriage, dismantle that beforehand.

Shove the pull-back cap (4) to another bearing (7).

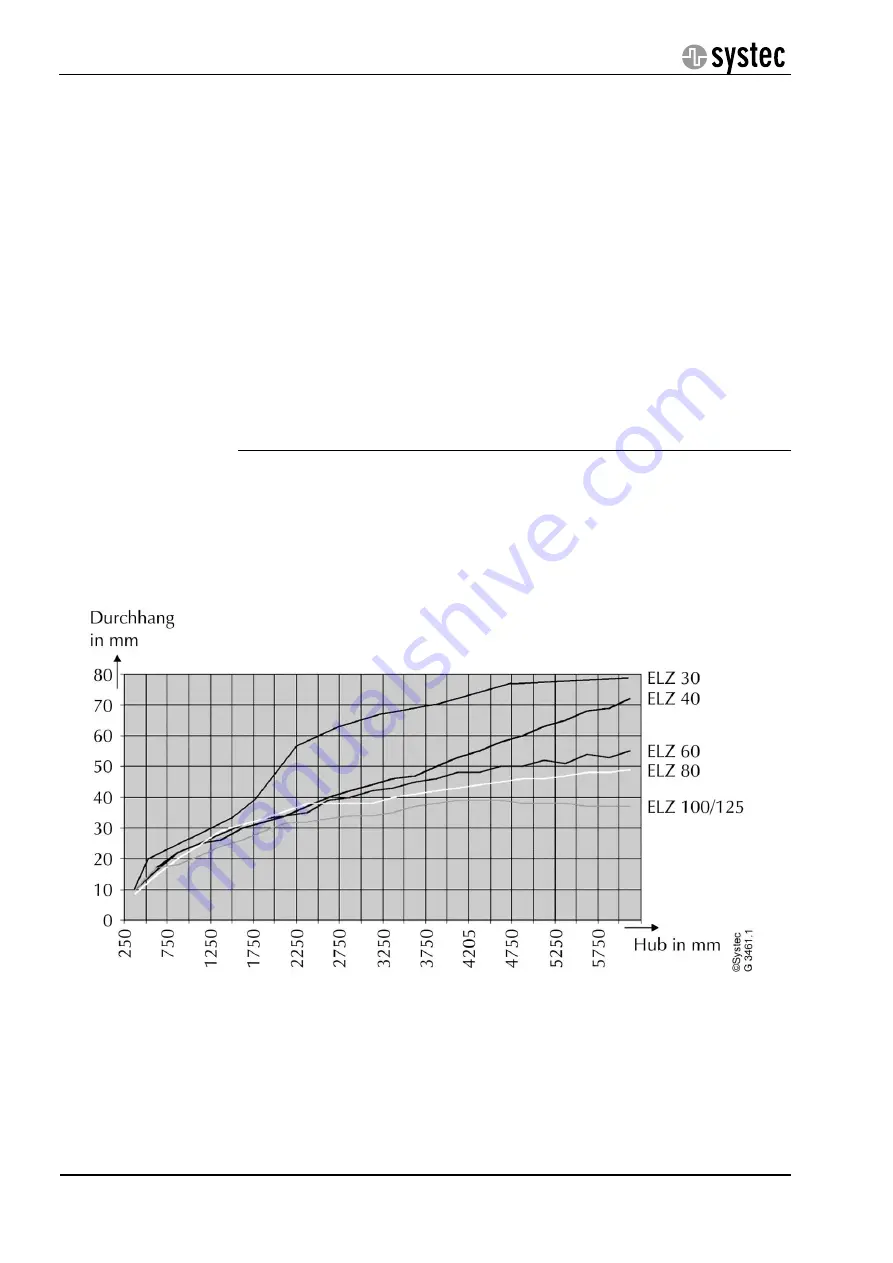

Exert the prescribed force (see table) a tension spring balance in

the middle of belt. - Compare the resulting “sag” (f) with the slack-

ened belt.

Compare the value with the diagram, and if necessary stretch or

slacken the belt.

Adjust the stud screws (2) with a hex. socket screw wrench.

The stud screws (2) must be bonded with the locking device.

Both screws (2) must be screwed in equally deep. Check with a

steel tape.

Screw on the pull-back cap (4) again.

Axis-scale

spring balance applied force

ELZ 30

20 N

ELZ 40

20 N

ELZ 60

30 N

ELZ 80

50 N

ELZ 100

50 N

ELZ 125

50 N

Fig. 5 Sag of belt (Durchhang) plotted against stroke (Hub)

6.4.2

Tooth belt tension axis type DuoLine Z

The toothed belt tension is set correctly ex works. A correction is unnec-

essary in normal operation.