699-41-20.1

-

29 -

6.7.10

Lubrication axis type DuoLine

All linear units are provided in the factory with the required lubricant

quantities. The maintenance intervals are determined by the number of

operating hours, loads and ambient influences. For servicing, the guide

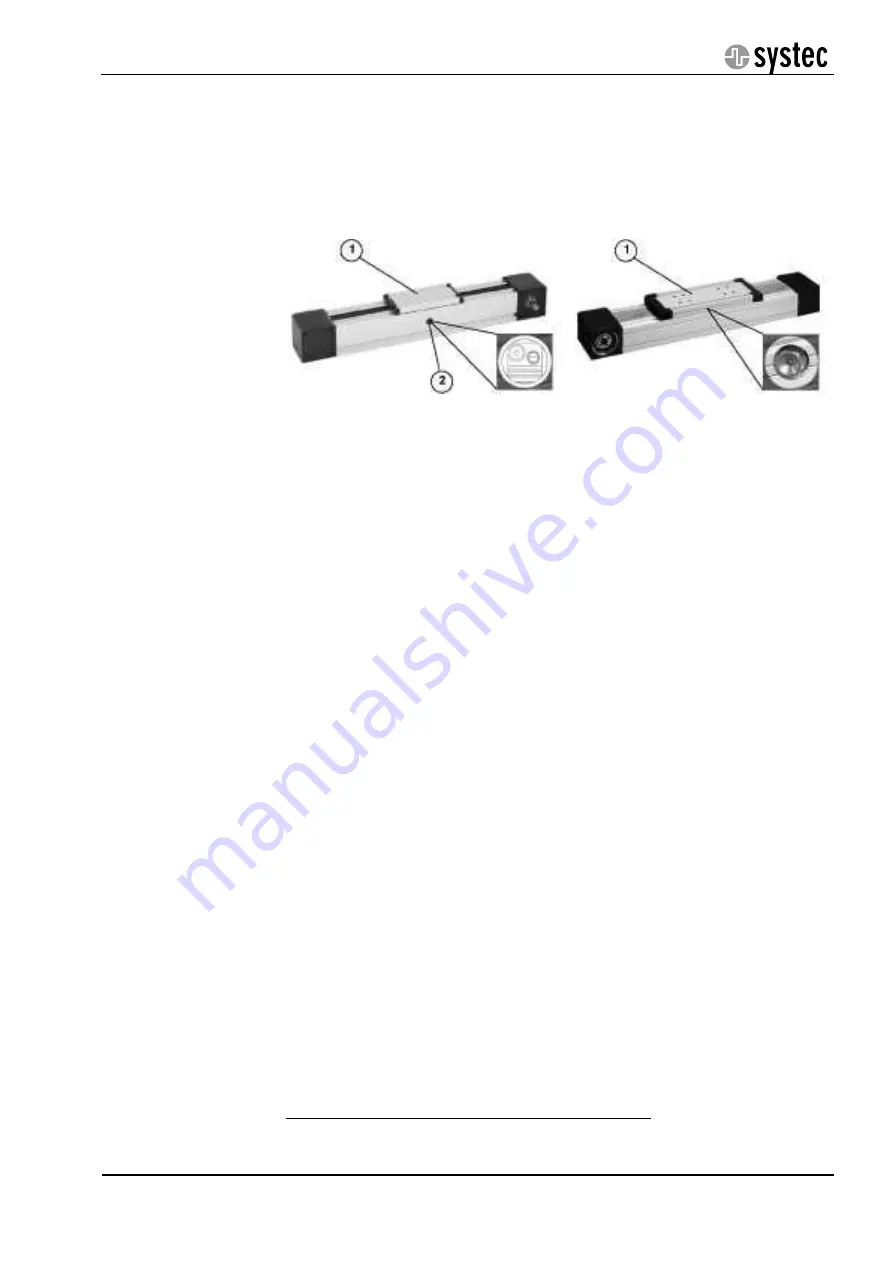

slide (1) is to be positioned centrally over the cover (2) and opened.

Fig. 20 Slide position for maintenance purposes

6.7.10.1

Guide shaft lubrication

Lubrication of the

guide shaft

Oiled felt strips are for lubricating (cleaning) the guide shafts.

The felt strips must be re-oiled periodically, according to the stressing,

via the shaft lubrication system.

Lubrication interval

First lubrication after approx. 2000 hours run.

Next interval: every 1000 hours run

Lubricant

Recommended lubricants:

Oil with viscosity of approximately 200 mm

2

/s at T = 40 °C

E.g. SAE 90 transmission oil.

6.7.10.2

Spindle lubrication

Spindle lubrication

Clean grease and oil from the lubrication point before lubricating. Ensure

that the grease gun is axially aligned with the flow direction of the

funnel-type lubricating nipple.

A high-pressure grease gun with a needle extrusion tip must be used to

lubricate the RK DuoLine 50x50, 80x80 and 80x120(II) units.

A high pressure grease gun with an extrusion tip must be used to lubricate

the RK DuoLine 80, 120 and 160 units.

Lubrication interval

Lubrication every 300 km

(Recommended lubricating interval taking the environmental factors and

loading data specified in these assembly instructions into consideration.)

Lubricant

Recommended lubricants: Grease in accordance with DIN 51818

Viscosity class: NLGI class 1, NLGI class 00

For use in max. range:

Grease in accordance with DIN 51818 Viscosity class NLGI class 2

Lubricant quantities

Version

Lubricant quantities

DuoLine 50x50

2 x 1 cm3