699-41-20.1

-

35 -

200

32 x 10

4,00

200

32 x 20

4,00

200

32 x 32

4,00

6.8.1.4

Axis type QS_ 60, 80, 100

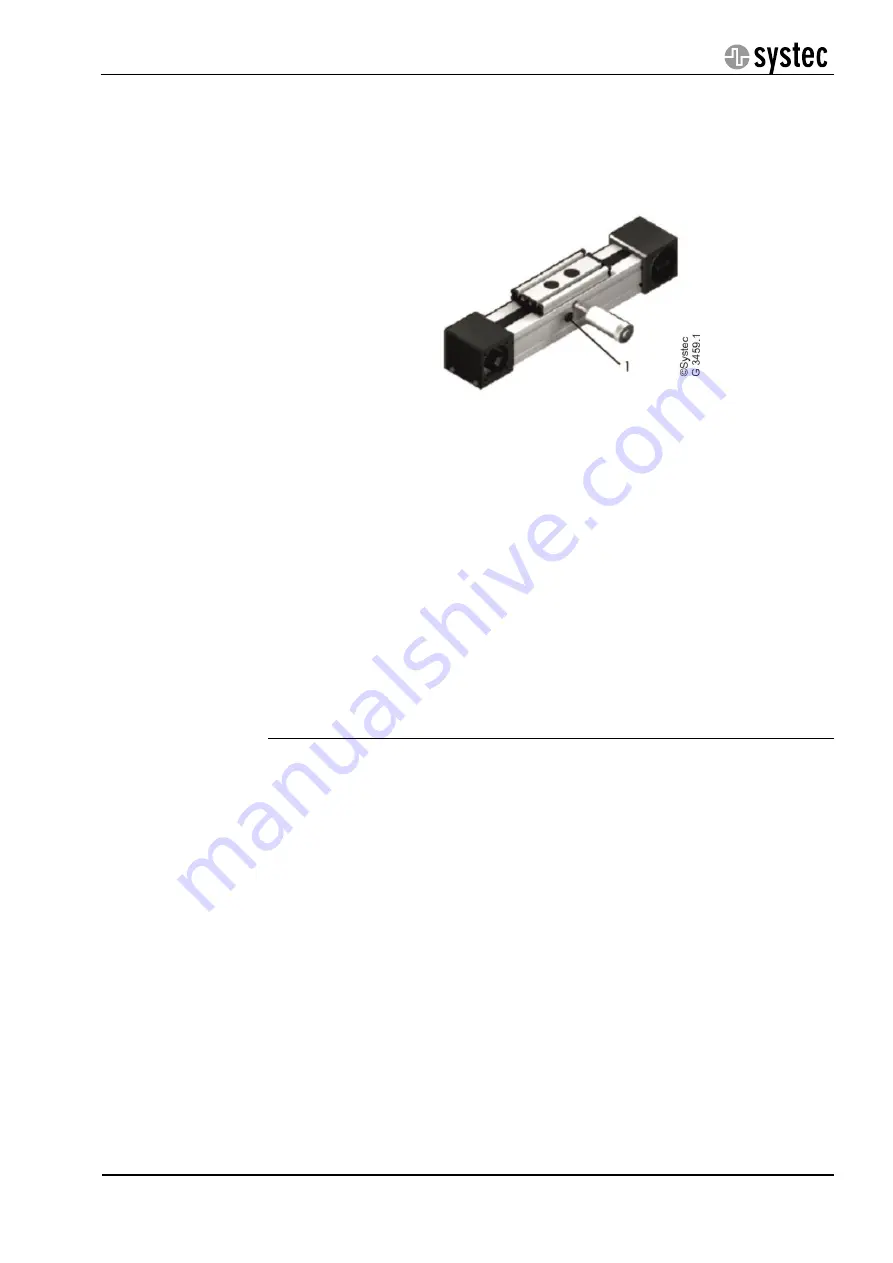

Fig. 26 Lubrication leading-nut

Dismount cover cap (1).

Drive the carriage through the service position until you can see

the first greasing nipple (2) in the grease hole.

Re-grease felt now with a grease gun.

Move the carriage to the second greasing nipple and re-grease

here as well.

Lubricant

Bearing grease based on DIN 51825 (see Chap. 6.6).

Lubrication interval

The required regreasing intervals depend on environmental conditions,

the standardrecommendation is once per 1.000 km.

6.8.1.5

Lubrication amounts for the regreasing axis type QS_

Axis size

Pitch

Regreasing [g]

60

KG 16 x 05

1,33

60

KG 16 x 10

0,84

60

KG 16 x 16

1,00

80

KG 20 x 20

3,00

80

KG 25 x 05

2,00

80

KG 25 x 10

3,00

100

KG 32 x 05

3,00

100

KG 32 x 10

4,00

100

KG 32 x 32

4,00