pag.

4

INDUSTRIAL PC - COPILOT 15,6"

Order 2E00xxxx

November 2020 - Rev. 1.2

4. Description and

operation

The PC switches on automatically with the presence of

the input power supply: it may take several seconds

before the start screen appears with the "System" logo.

Copilot 15,6''

has two gigabit-Ethernet networks, two

RS232 serial ports, a PS2 mouse and keyboard port,

and USB 2.0 ports; as an option you can request con-

nections for USB3.0, display port, DVI or external VGA

for a remote monitor, audio connection.

The main operating systems can be pre-installed on the

terminal: Windows 10 Iot, Linux Debian, Windows7 and

Windows 8.1.

After shutdown of the operating system it is possible

to reignite the

Copilot 15,6''

disconnecting for 10

seconds and reconnecting the external 24VDC / 48VDC

power supply or by pressing the optional power button.

Copilot 15,6''

can also be turned on by WakeOn-Lan

commands from an external PC connected to the ter-

minal's Ethernet network.

4.1 Installation in the hanging

version (VESA100)

To correctly mount the

Copilot 15,6''

in the hanging ver-

sion on the VESA100 arm, follow the instructions below:

- Remove the

Copilot 15,6''

from the packaging and

place it on a flat surface free from objects, placing a

soft cloth on the table itself to avoid scratching the

glass during the installation phase. Place the

Copilot

15,6''

with the glass facing the table. Avoid placing the

terminal in a vertical position only slightly or slightly

resting on the mechanism to avoid damage due to the

unstable position.

- Position the cables that must be connected to the

Co-

pilot 15,6''

on the fixing arm, making sure that they

protrude for about 20cm beyond the fixing point of the

arm itself: cables that will be connected on the back of

the PC itself.

- Typically all connecting cables are connected from the

bottom side of the

Copilot 15,6''

- Place the

Copilot 15,6''

on the VESA arm

- It is possible to fix the

Copilot 15,6''

to the arm using

the M4 screws supplied. In the event that the screws

must be replaced to fit the used arm, pay attention

not to exceed the length of the inside thread for more

than 8mm from the outer edge, to avoid damaging the

internal components.

- Only connect the communication cables: USB, Ether-

net, which are all on the underside, to the VESA arm only.

- The power connector is located on the bottom side, to

be connected to the end.

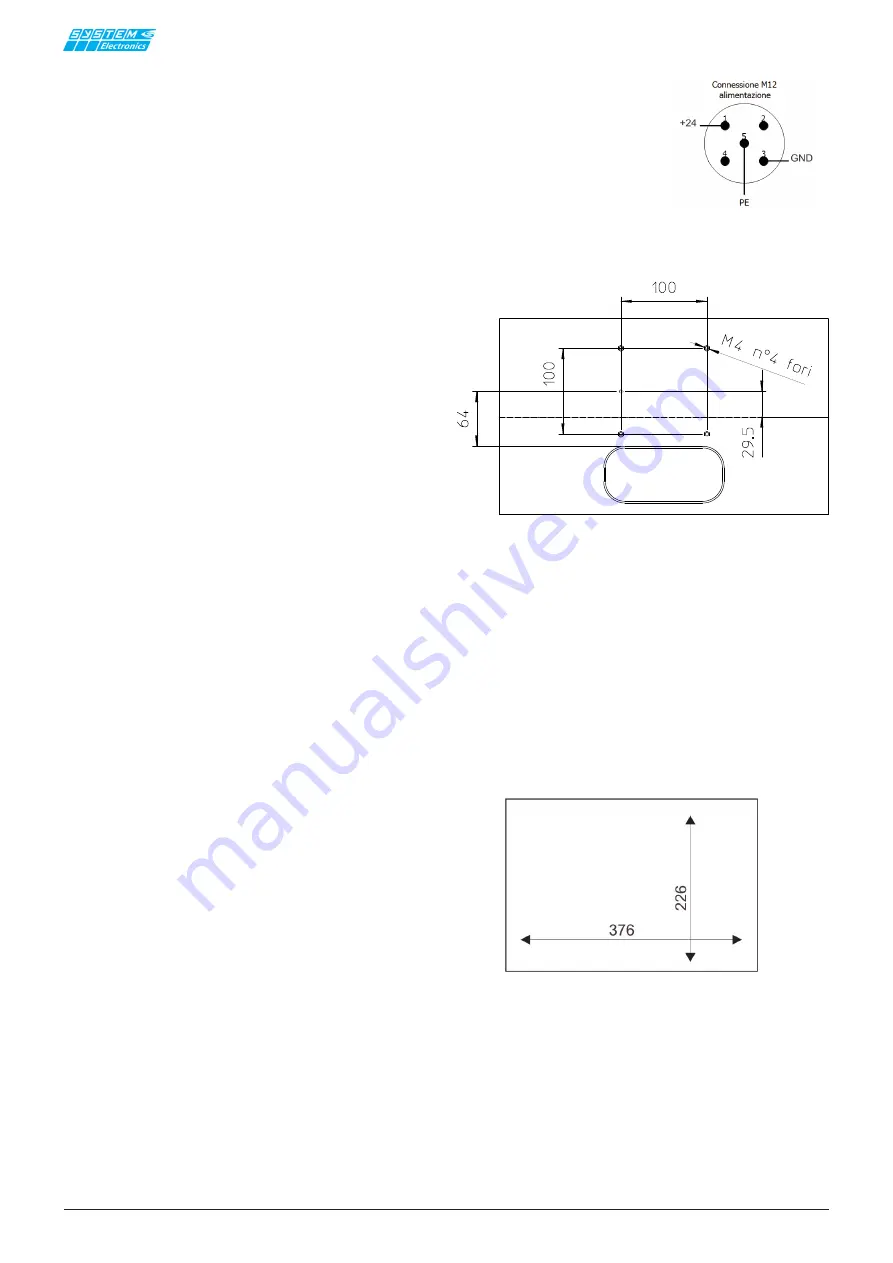

The pinout of the power connector is shown below, as

shown in the manual section:

It is possible to adjust and tighten the VESA 100 joint

of the optional 15.6 '' Copilot column by adjusting the

knobs on the side of the joint.

4.2 Panel mounting

- Drill the panel according to the indicated mea-

surements: 376 x 226

-

Remove the

Copilot 15.6 ''

from the packaging

and place it on a flat surface free of objects, placing a

soft cloth on the table itself to avoid scratching the glass

during the installation phase. Place the 15.6 '' Copilot

with the glass facing the table. Avoid even temporarily

placing the terminal in a vertical position or slightly

resting on the mechanics to avoid damage due to the

unstable position.

- Remove the power connector.

1:

+24V

3:

GND

5:

PE

Figure 4.1.1

Figure 4.1.2 Copilot 15.6 ”fixing positioned on the VESA arm.

Detail of the position of the fixing holes with respect to the axis

and with respect to the lower connectors.

4.2.1 Panel drilling template