D200-301-00

I56-4224-002

Pittway Tecnologica S.r.l. Via Caboto 19/3, 34147 TRIESTE, Italy

≤

M4

50-60 mm

107 mm

+

=

246 g

(66 g)

132 g

48 g

-30°C

40°C

B501RF

32 mm

104

mm

62 mm

DESCRIPTION

The 22051E-RF radio sensor is a battery operated RF device designed for

use with the M200G-RF radio gateway. It contains a wireless transceiver

and runs on an addressable fire system (using a compatible proprietary

communication protocol).

It is an optical smoke sensor.

The sensor plugs into the B501RF wireless sensor base.

This device conforms to EN54-25 and EN54-7. It complies with the

requirements of 2014/53/EU for conformance with the RED directive.

SPECIFICATIONS

Supply Voltage:

3.3 V Direct Current max.

Standby Current:

@ 3V: 120 µA (typical in normal operating mode)

Red LED Current Max: 4mA

Re-sync time:

35s (max time to normal RF communication from

device power on)

Batteries:

4 X Duracell Ultra123

Battery Life:

4 years @ 25

o

C

Radio Frequency:

865-870 MHz;

RF output power:

14dBm (max)

Range:

500m (typ. in free air)

Relative Humidity:

10% to 93% (non-condensing)

INSTALLATION

This equipment and any associated work must be installed in accordance

with all relevant codes and regulations.

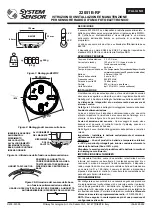

Figure 1 details the installation of the B501RF base.

Spacing between radio system devices must be a minimum of 1m

Figure 2 details attaching the sensor head to the base.

Anti-Tamper Features

The base includes a feature that, when activated, prevents removal of the

sensor from the base without the use of a tool. See Figures 3a and 3b for

details on this.

Head Removal Warning -

An alert message is signalled to the CIE via the

Gateway when a head is removed from its base.

Figure 4 details the battery installation and the location of the rotary

address switches.

Important

Batteries should only be installed at the time of commissioning

Warning

Using these battery products for long periods at temperatures below

-20°C can reduce the battery life considerably (by up to 30% or more)

Observe the battery manufacturer’s precautions for use and

requirements for disposa

l

SETTING THE ADDRESS

Set the loop address by turning the two rotary decade switches on the

underside of the sensor (see figure 4), using a screwdriver to rotate the

wheels to the desired address. The device will take one sensor address

on the loop. Select a number between 01 and 159 (Note: The number of

addresses available will be dependent on panel capability, check the panel

documentation for information on this).

PROGRAMMING

To load network parameters into the RF sensor, it is necessary to link the RF

gateway and the RF sensor in a configuration operation. At commissioning

time, with the RF network devices powered on, the RF gateway will

connect and programme them with network information as necessary. The

RF sensor then synchronises with its other associated devices as the RF

mesh network is created by the gateway. (For further information, see the

Radio Programming and Commissioning Manual

- ref. D200-306-00.)

NOTE:

Do not run more than one interface at a time to commission

devices in an area.

22051E-RF

WIRELESS OPTICAL SMOKE SENSOR

INSTALLATION AND MAINTENANCE INSTRUCTIONS

E N G L I S H

Figure 1: B501RF Mounting

Figure 2: Attaching Sensor Head to Base

Figure 3a: Activation of Tamper Resist Feature

PLASTIC LEVER

BREAK TAB AT DOTTED LINE BY

TWISTING TOWARDS CENTRE OF

BASE

Figure 3b: Removing Sensor Head From Base

USE A SMALL-BLADED SCREWDRIVER TO PUSH

PLASTIC IN THE DIRECTION OF THE ARROW

LINE UP MARK ON

SENSOR HEAD

WITH BULGE ON

BASE AND TURN

CLOCKWISE

BULGE

MARK ON

SENSOR HEAD

I 56- 4224- 002