Pittway Tecnologica Srl, Via Caboto 19/3, 34147 Trieste, ITALY

I56-3310-003

D200-51-00

22051EISE

0832

0832-CPD-0199

102 mm

47 mm

B501AP

-20°C

60°C

T4

-20°C

40°C

T5

112.5g

INSTALLATION AND MAINTENANCE INSTRUCTIONS

FOR MODEL 22051EISE INTRINSICALLY SAFE

INTELLIGENT PHOTO ELECTRONIC SMOKE SENSOR

EN

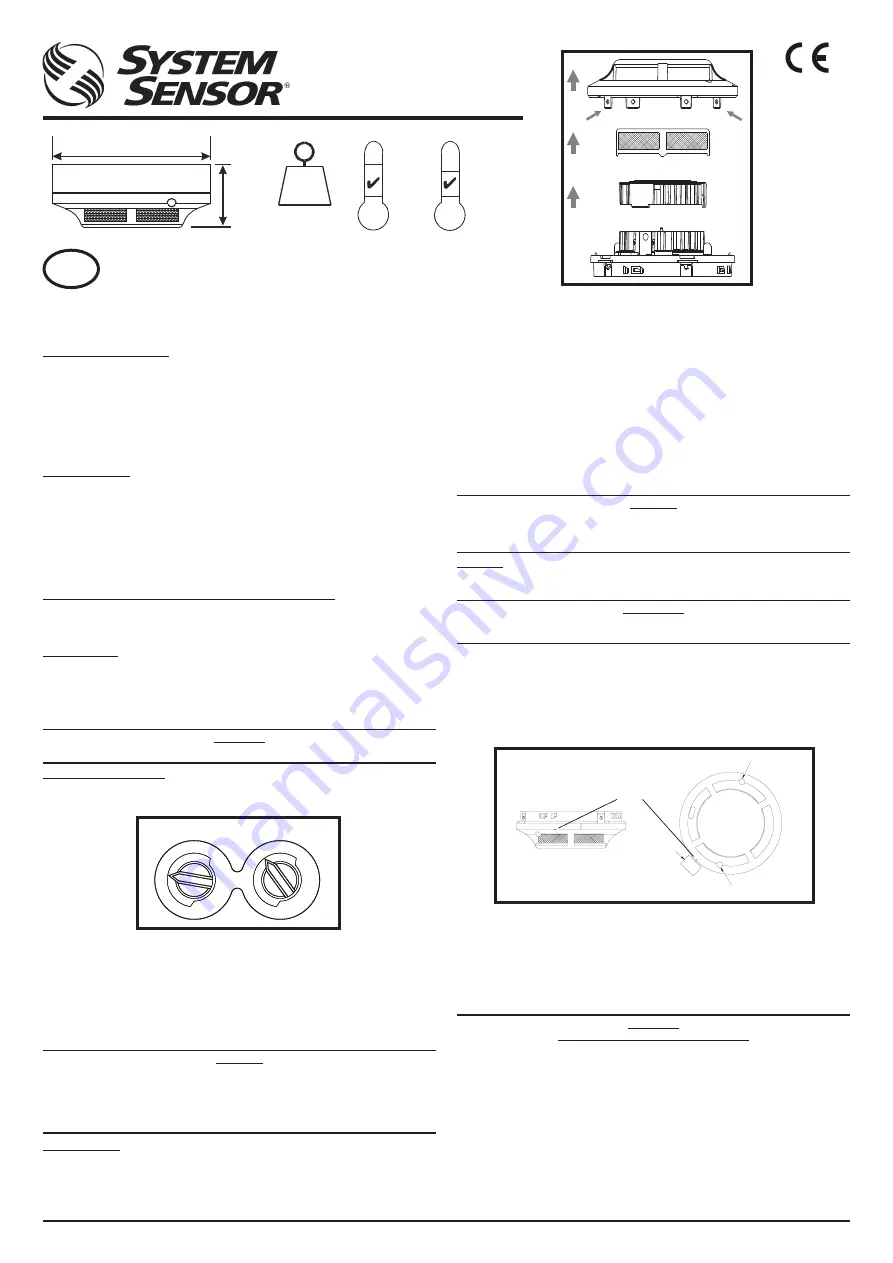

Figure 1: Cleaning

the Sensor

Before installing the sensor, please thoroughly read System Sensor Europe’s “Guide

to Intelligent Fire Systems”. Copies of this manual are available at no charge from

System Sensor.

GENERAL DESCRIPTION

Model 22051EISE is an intrinsically safe smoke detector that combines a photo

electronic sensing chamber with analogue addressable communications and is for use

in hazardous areas where potentially explosive atmospheres are likely to arise. The

classification of equipment required must be confirmed with your responsible authority.

The sensor communicates via a dedicated Galvanic Isolator Barrier with an IST200

Translator Module which relays the data to the Control Panel. Rotary decade switches

are provided for setting the sensor address.

Two LEDs on each sensor provide a local 360° visible sensor indication.

SPECIFICATIONS

Operating Voltage Range:

15 to 24 VDC

Max. Avg. Standby Current:

220 µA @20 VDC (One communication every 5

sec. With LED blink enabled)

Max. Alarm Current (LED on):

3 mA @ 24 VDC

Operating Humidity Range:

10% to 93% Relative Humidity, Non-Condensing

Intrinsic Safety Rating:

Ex ia IIC T5, T4

This detector has been independently tested and certified to EN54 part 7: 2000 and

BASEEFA approved for intrinsic safety.

ACCESSORIES (Available Separately from System Sensor)

IST200 Translator Module

May drive up to 15 22051EISE sensors

Pepperl and Fuchs Y72221

Dedicated Galvanic Isolator Barriers for

22051EISE (drive up to 15 sensors).

WIRING GUIDE

Refer to the installation instructions supplied with the IST200 Translator Module, and

B501AP Base for wiring details.

Note 1:

All wiring must conform to applicable local and national codes and regulations.

Note 2:

Verify that all sensor bases are installed and that polarity of the wiring is

correct at each base.

WARNING

Disconnect loop power before installing sensors. Notify proper authorities.

SENSOR INSTALLATION

1. Set the sensor address (see figure 2) by turning the two rotary switches, selecting a

number between 01and 99. Record the address on the label attached to the base.

4

4

0

2

3

1

0

ONES

TENS

2

3

1

6 7

5

5

9

8

6

9

8

7

2. Insert the sensor into the base and rotate it clockwise until it locks into place.

3. After all the sensors have been installed, apply power to the system.

4. Test the sensor as described under

TESTING.

5. Reset the sensor by communication command from the panel.

Tamper-Resistance.

Model 22051EISE includes a feature that, when activated, prevents removal of the

sensor without the use of a tool. Refer to the installation instructions for the sensor

base for details of how to use this feature.

CAUTION

Dust covers help to protect units during shipping and when first installed.

They are not intended to provide complete protection against contamination

therefore sensors should be removed before construction, major re-decoration

or other dust producing work is started. Dust covers must be removed before

system can be made operational.

MAINTENANCE

Before cleaning, disable the system to prevent unwanted alarms:

1. Remove the sensor to be cleaned from the system.

2. Gently release each of the four cover removal tabs that hold the cover in place (see

figure 1) and remove the cover.

3. Vacuum the outside of the screen carefully without removing it.

4. Remove the sensor screen. Pull the screen straight away from the sensing chamber

until it snaps out of place.

5. Remove the chamber cover by pulling it gently away from the sensing chamber until

it snaps out of place.

6. Use a vacuum cleaner and/or clean, compressed air to remove dust and debris

from the sensing chamber and sensing chamber cover.

7. Re-install the sensing chamber cover by aligning the arrow moulded on the cover

with the arrow printed on the circuit board and sliding the cover over the chamber,

gently pressing it home until it snaps into place.

8. Re-install the sensing chamber screen by sliding it over the sensing chamber.

Rotate the screen until the locating tabs on the bottom rim locate in the cutouts in

the chamber base, and the top of the screen is flush with the top of the chamber.

9. Re-install the sensor cover. Use the cover removal tabs and LEDs to align the cover

with the sensor. Snap the cover into place.

10. When all sensors have been cleaned, restore power to the loop and test the sensor(s)

as described under

TESTING

.

CAUTION

The Detector has a plastic enclosure that may present an electrostatic risk and

must not be installed in a position where it may be subject to a high dust-laden

air flow. Clean only with a damp cloth and do not rub.

TESTING

Sensors must be tested after installation and following periodic maintenance. Disable

the zone or system undergoing maintenance to prevent unwanted alarms.

IMPORTANT

If testing is carried out using non-intrinsically safe methods, it must be

conducted outside the hazardous area.

Test the sensors as follows:

Magnet Test Method

1. Test the sensor by positioning the test magnet (model M02-04-00 optional) against

the sensor body approximately 2cm from LED 1, indicated by a mark on the detector

cover as shown in figure 3.

2. Both LED’s on the detector should latch into alarm within 30 seconds, activating the

control panel.

Smoke Method

1. Using generated smoke, or synthetic smoke aerosol from an approved manufacturer

such as No Climb Products Ltd, subject the detector to controlled amounts of smoke

in accordance with local codes of practice and manufacturer recommendations.

2. Both LED’s on the detector should latch into alarm within 30 seconds, activating the

control panel.

After completion of the test notify the proper authorities that the system is operational.

WARNING

LIMITATIONS OF SMOKE DETECTORS

Smoke detectors must be used in conjunction with compatible equipment.

Smoke detectors will not sense fires which start where smoke does not reach the

detectors.

A detector may not detect a fire developing on another level of a building.

Smoke detectors also have sensing limitations. Consideration must be made of the

environment when selecting fire detectors.

Smoke detectors cannot last forever.

Smoke detectors contain electronic parts. Even

though detectors are made to last over 10 years, any of these parts could fail at any

time. Therefore, test your smoke detector system at least semiannually. Clean and take

care of your smoke detectors regularly. Taking care of the fire detection system you

have installed will significantly reduce your product liability risks.

Figure 3: Test Magnet Position

Mark on Cover

LED 2

LED 1

Test Magnet

Figure 2: Rotary Decade Address Switch

TENS

UNITS