[6.1] Smoke Entry Tests

[6.1.1] Air Flow

To verify sufficient sampling of ducted air, use a manom-

eter to measure the differential pressure created from air

flow across the sampling tubes. The pressure should mea-

sure no less than 0.01 inches of water and no greater than

1.20 inches of water.

[6.1.2] Smoke Response

To determine if smoke is capable of entering the sensing

chamber, visually identify any obstructions. Plug the ex-

haust and inlet tube holes to prevent ducted air from carry-

ing smoke away from the detector head, then blow smoke

such as cigarette, cotton wick, or punk directly at the head

to cause an alarm. REMOVE THE PLUGS AFTER TESTING

OR THE DETECTOR WILL NOT FUNCTION PROPERLY.

[6.1.3] Filter Replacement

The filters do not substantially affect smoke behavior even

when they are up to 90% clogged. Quarterly visual inspec-

tion is usually often enough to determine if filters should

be replace because only a high percentage of contamina-

tion affects duct detector performance.

[6.2] Standby, Alarm, And Sensitivity Tests

[6.2.1] Standby And Trouble

Standby-

Check for the presence of the blinking red LEDs

(blinks about every 10 seconds) through the

transparent housing cover. If the APA451 acces-

sory is used, its green Power LED should be illu-

minated continuously.

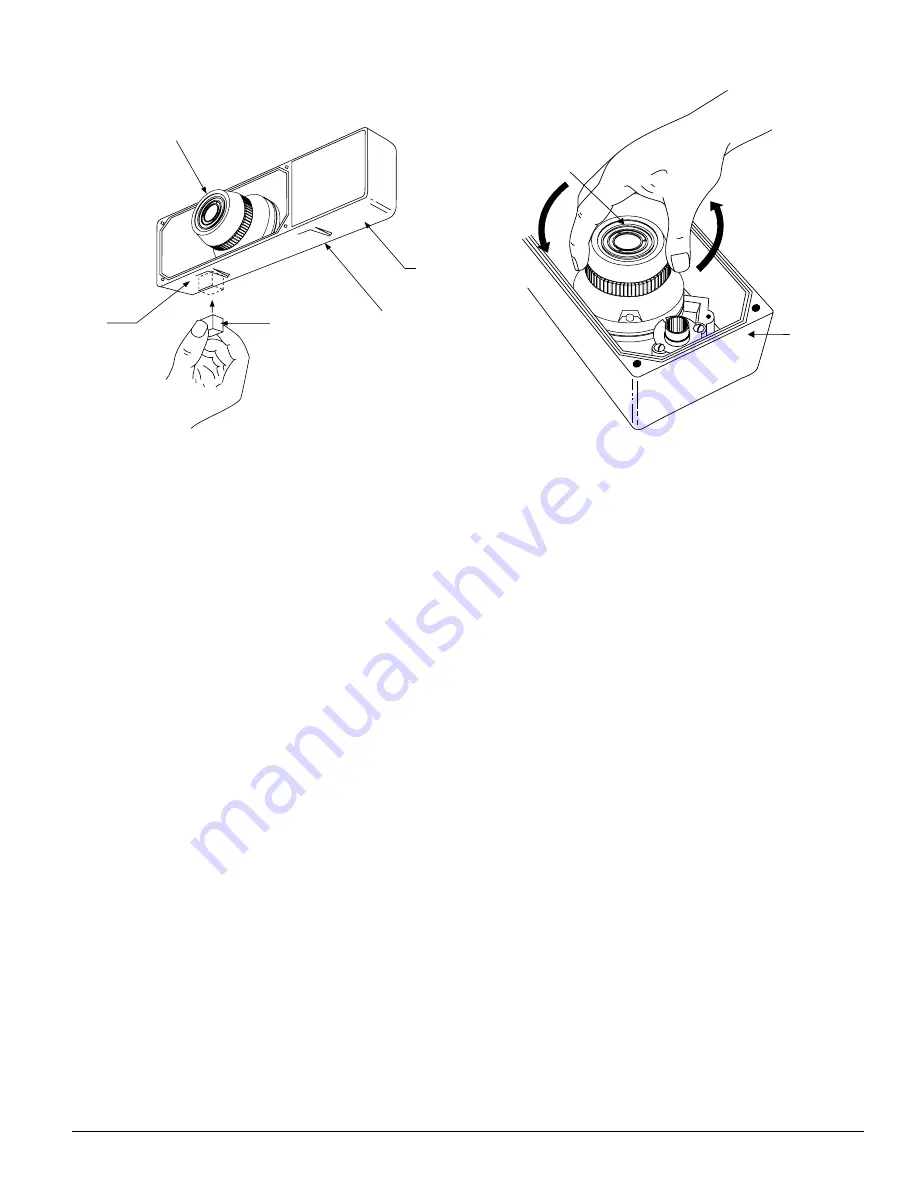

Figure 10. Testing detector alarm:

Figure 11. Detector head removal:

TEST

LOCATOR

TEST

MAGNET

PAINTED SIDE

TOWARD HOUSING

DUCT

HOUSING

DETECTOR

HEAD

RESET

LOCATOR

TWIST

COUNTERCLOCKWISE

TO REMOVE

DUCT

HOUSING

TWIST

CLOCKWISE

TO INSTALL

DETECTOR

HEAD

A78-2138-00

A78-2139-00

Trouble-

If the detector LEDs do not blink or if the

APA451 Power LED is not illuminated, the detec-

tor lacks power (check wiring, panel, or power

supply), the head is missing (install), or the unit

is defective (return for repair).

Test-

The trouble condition can be caused

intentionally to verify correct operation of the

system. Remove power to the unit, remove the

detector head (see Figure 11), or place the M02-

04-00 magnet into the Reset locator, as shown in

Figure 10. These actions should cause a trouble

condition locally and at the system control

panel.

[6.2.2] Alarm Tests

[6.2.2.1] M02-04-00 Magnet Test

1. Place the painted surface of the magnet into the Test lo-

cator molded into the side of the housing (see Figure

10).

2. The red alarm LEDs on the detector should latch on, as

should any accessories (PA400, RA400Z, RTS451,

APA451). Verify auxiliary functions (such as fan shut-

down) and system control panel alarm status.

3. Place the painted surface of the magnet into the Reset

locator molded into the side of the housing (see Figure

10). This should clear the latched alarm condition at the

detector. If a system control panel is used, the panel may

also require resetting.

[6.2.2.2] RTS451/RTS451KEY Remote Test Station

The RTS451/RTS451KEY Remote Test Station facilitates test

D400-13-00

9

I56-555-08

Summary of Contents for DH400ACDC

Page 14: ...NOTES D400 13 00 14 I56 555 08 ...