FAAST 7100X

INSTALLATION AND MAINTENANCE INSTRUCTIONS

© Pertronic Industries Ltd

24

FAAST XS (7100X) Installation Guide Iss 1.0, 201606

F2e Signalling

All signalling between the ASD system and Fire Alarm Panel/CIE should be verified in accordance with the design.

In particular the signalling and response to each Alarm level and Fault conditions should be checked and verified.

Where an ASD system provides local Disablement or Isolation it should be verified that this condition is signalled to

the Fire Alarm Panel/CIE

Any “cause and effect” requirements, particularly in relation to the integration with automatic suppression systems

should be verified

F2f

System Check

After initial commissioning, it is prudent to monitor detector performance by turning Trend Log ON for an

appropriate period, then review the log to verify the settings are suitable for the site (refer to Section C, Device

Details)

F2g System

Handover

During the commissioning all results shall be recorded. These along with all configuration data shall be submitted

as part of the commissioning certificate.

All relevant drawings shall be submitted to include the pipe layout, hole sizes, sampling point positions and detector

locations, and shall be deemed part of the system handover.

All the collated documentation along with a signed certificate should be issued to the customer.

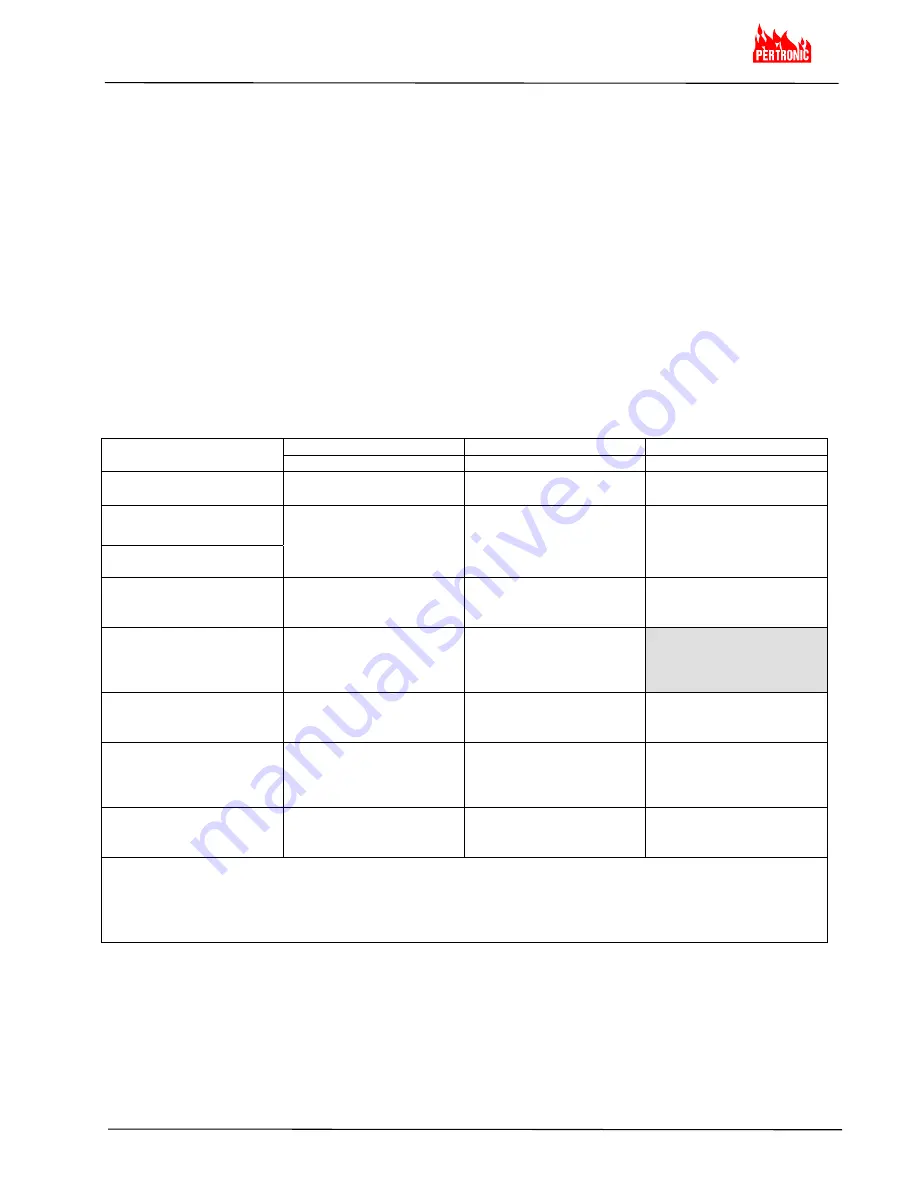

Sensitivity Class vs Detection Requirements:

Table 7 : Sensitivity Class vs Detection Requirements

Class (EN54-20)

Class A

Class B

Class C

Very High Sensitivity

Enhanced Sensitivity Normal

Sensitivity

TF2x End of Test

Condition

1.15% obs/m (0.05dB/m)

3.4% obs/m (0.15dB/m)

36.9% obs/m (2dB/m)

Description:

Smoke is not visible due

to low quantity and/or high

dilution due to air

movement

Smoke is visible but

insufficient to be detected

by Point or Beam

detectors

Smoke is visible and

sufficient to be detected

by Point or Beam

detectors

ASD Sampling Type

Primary Detection:

sampling where smoke is

likely to travel

Best

Small Areas Only

Not Appropriate

Secondary Detection:

sampling holes positioned

according to Point

detector code

Early Warning

Challenging Applications

Appropriate

(prescriptive design

may be used)

Localised Sampling:

customised protection of

specific equipment

High Risk

Low Risk

Not Appropriate

In-Cabinet Sampling:

localised sampling

High Risk

Low Risk

Not Appropriate

Duct Sampling:

High Risk

Low Risk

Not Appropriate

Other Motivators:

•

extreme

environments

•

restricted/difficult

access

•

exceptional ceiling height

•

heat

barriers

•

aesthetics

•

risk of mechanical damage

•

anti-vandal

systems

•

hazardous

environment