1

I56-3102-003

7/8/2019

D4120A Duct Smoke Detector

D4SA Sensor Component

D4P120A Power Board Component

INSTALLATION AND MAINTENANCE INSTRUCTIONS

3333 Unity Drive, Mississauga, ON L5L 3S6

1-800-SENSOR2, FAX: 905-812-0771

www.systemsensor.ca

TABLE OF CONTENTS

PAGE

[1] Limitations of Duct Smoke Detectors

1

[2] Exploded View of Duct Smoke Detector Components 2

[3] General Description

2

[4] Contents of Duct Smoke Detector Kit

2

[5] Detector Installation

2

[6] Sampling Tube Installation

3

[7] Measurement Tests

3

[8] Field Wiring Installation Guidelines

4

[9] Unit Configuration

5

[10] Detector Status Indication

6

[11] Interconnection (Multiple Fan Shut Down)

6

[12] Verification of Operation

6

[13] Detector Cleaning Procedures

7

[14] Sensor replacement

7

[15] Optional Accessories

7

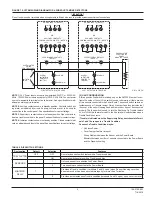

Wiring Diagrams

5-7

Warranty 8

BEFORE INSTALLING

Read the System Sensor Guide for Proper Use of Smoke Detectors in Duct

Applications (HVAG53), which provides information on detector spacing,

placement, zoning, wiring, and special applications. This manual is available

online at www.systemsensor.ca. CAN/ULC S524 should also be referenced

for detailed information.

NOTICE:

This manual shall be left with the owner/user of this equipment.

NOTE:

The D4120A duct detector consists of D4P120A Power Board component and the D4SA Sensor component.

SPECIFICATIONS

Operating Temperature:

D4120A & D4SA: –4° to 158° F (–20° to 70° C) D4P120A: –40° to 158° F (–40° to 70° C)

Storage Temperature:

D4120A & D4SA: –22° to 158° F (–30° to 70° C) D4P120A: –40° to 158° F (–40° to 70° C)

Humidity:

0% to 95% Relative Humidity Non-condensing

Air Velocity:

100 to 4000 ft./min. (0.5 to 20.3 m/sec.)

D4120A Footprint Dimensions:

Rectangular - 14.38 in L x 5 in W x 2.5 in D (37cm L x 12.7cm W x 6.36cm D)

Square - 7.75 in L x 9 in W x 2.5 in D (19.7cm L x 22.9cm W x 6.35cm D)

D4SA/D4P120A Footprint Dimensions: 7.75 in L x 5 in W x 2.5 in D (19.7cm L x 12.7cm W x 6.35cm D)

D4120A Weight:

2.5 pounds; 1.14 kg

Electrical

Power supply voltage:

20-29 VDC

24 VAC 50-60-Hz

120 VAC 50-60 Hz

Input capacitance:

270 µF max.

270 µF max.

N/A

Reset Voltage:

3.0 VDC min.

2.0 VAC min.

10 VAC min.

Reset Time (with RTS451):

.03 to 0.3 sec.

.03 to 0.3 sec.

.03 to 0.3 sec.

Reset Time (by power down):

0.6 sec. max.

0.6 sec. max.

0.6 sec. max.

Power Up Time:

35 sec. max.

35 sec. max.

35 sec. max.

Alarm response time:

15 sec.

15 sec.

15 sec.

Sensitivity Test:

See detector label

See detector label

See detector label

Current Requirements (Using No Accessories)

Standby current

21 mA @ 24 VDC

65 mA RMS @ 24VAC 60Hz

20 mA RMS @ 120 VAC 60 Hz

Alarm current

65 mA @ 24 VDC

135 mA RMS @ 24 VAC 60 Hz 35 mA RMS @ 120 VAC 60 Hz

CONTACT RATINGS

Alarm initiation contacts

(SPST)

2.0A @ 30 VDC (resistive)

Alarm auxiliary contatcs

(DPDT)

10A @30 VDC (resistive)

10A @250 VAC (resistive)

1

/

2

HP @240 VAC

1

/

4

HP @120 VAC

NOTE: Alarm auxiliary contacts shall not be connected to initiating

circuits of control panels. Use the alarm initiation contact for this

purpose.

Supervisory Contacts

(SPDT)

2.0A @ 30 VDC (resistive)

2.0A @ 125 VAC (resistive)

ACCESSORY CURRENT LOADS AT 24 VDC

DEVICE

STANDBY

TROUBLE

ALARM

MHRA/MHWA

0mA

n/a

29mA Max.

RA400ZA

0mA

n/a

12mA Max.

RTS451

0mA

n/a

12mA Max.

RTS451KEYA

12mA

n/a

12mA Max.

NOTE: Any combination of accessories may be used such that the given

accessory loads are: 110mA or less at the Aux output, and 50mA or less at

the Alarm output.

IMPORTANT:

This detector must be tested and maintained regularly follow-

ing CAN/ULC S536 requirements. The detector should be cleaned at least

once a year.

[1] LIMITATIONS OF DUCT SMOKE DETECTORS

WARNING

The National Fire Protection Association has established that DUCT DETEC-

TORS MUST NOT BE USED AS A SUBSTITUTE FOR OPEN AREA DE-

TECTOR PROTECTION as a means of providing life safety. Nor are they a

substitute for early warning in a building’s regular fire detection system.

System Sensor supports this position and strongly recommends that the user

read NFPA Standards 90A, 72, 101and CAN/ULC S524. The D4120A Air

Duct Smoke Detectors are listed per ULC.

This device will not operate without electrical power. Fire situations may

cause an interruption of power. The system safeguards should be discussed

with your local fire protection specialist.

This device will not sense smoke unless the ventilation system is operating

and the cover is installed.

For this detector to function properly, it MUST be installed according to the in-

structions in this manual. Furthermore, the detector MUST be operated within

ALL electrical and environmental specifications listed in this manual. Failure

to comply with these requirements may prevent the detector from activating

when smoke is present in the air duct.

I56-3

10

2-00

3