6

I56-3102-003

7/8/2019

[10] DETECTOR STATUS INDICATION

Detector Staus is indicated by the LED sensor, and the correcsponding LED

on the power board. The power board has two separate LED’s to indicate the

status of each sensor connected to it. Refer to Table 3 on page 8 for more

details.

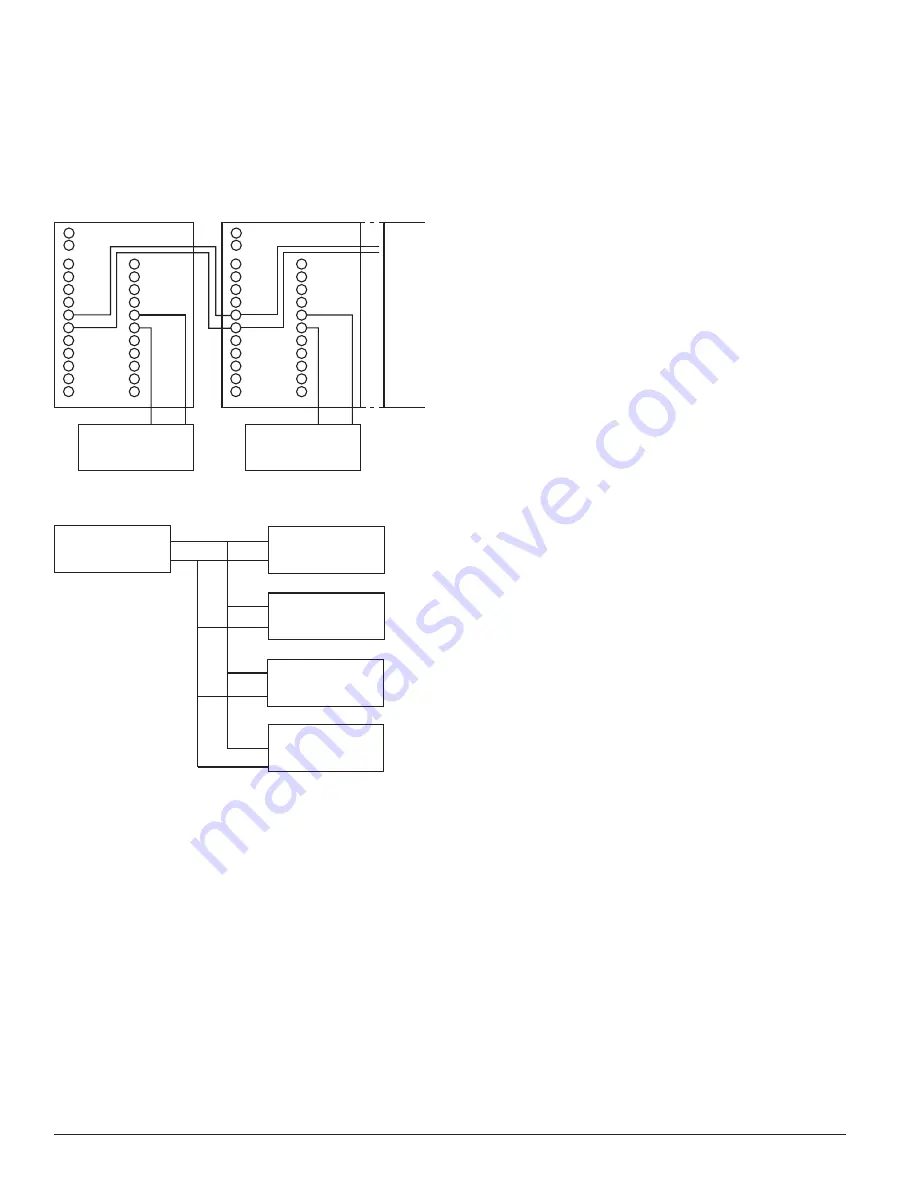

[11] INTERCONNECTION (MULTIPLE FAN SHUT DOWN)

When using the interconnect feature, an alarm from an initiating device will

switch the Aux Relays on the other devices interconnected.

FIGURE 8. MULTIPLE FAN SHUTDOWN

(INTERCONNECTION OF D4120A’S)

DETECTOR 1

120 VAC

D4120A

C, AUX A

NC, AUX A

50

DET.

MAX.

INT/AUX–

INT+

SYSTEM CONTROL

POWER, FAN

CONTROL OR

THERMOSTAT

SYSTEM CONTROL

POWER, FAN

CONTROL OR

THERMOSTAT

12

1

–

+

2

11

15

20

19

9

10

16

6

5

13

3

14

17

8

18

7

4

DETECTOR 2

120 VAC

D4120A

C, AUX A

NC, AUX A

INT/AUX–

INT+

12

1

–

+

2

11

15

20

19

9

10

16

6

5

13

3

14

17

8

18

7

4

H0552-00CDN

FIGURE 9. MULTIPLE FAN SHUTDOWN

(INTERCONNECTION OF D4120A TO DH100ACDC)

DH100ACDC

DH100ACDC

D4120A

D4120A

D4120A

H0617-00CDN

[11.1] IMPORTANT INTERCONNECTION NOTES

• When using the interconnect feature, all interconnected units must be

powered using the same independent supply.

• Polarity must be maintained throughout the interconnect wiring.

Connect the INT+ terminal on unit 1 to the INT+ terminal on unit 2 and

so on. Similarly, connect the INT/AUX- terminal on unit 1 to the INT/

AUX- terminal on unit 2 and so on.

• Up to 50 D4120A units may be interconnected.

• Up to 10 DH100ACDC units may be interconnected. Please note that

each of the 9 DH100ACDC units interconnected can be substituted by

three D4P120A units. Therefore, when using the interconnect feature

a single DH100ACDC can drive either 9 DH100ACDC’s or 27 D4120A

units.

NOTE: Alarm can be reset only at the initiating device and not at the devices

interconnected.

[12] VERIFICATION OF OPERATION

[12.1] FIELD SELECTABLE SETTINGS

Verify dip switch settings as per Table 2 on Page 5.

[12.2] POWERING THE UNIT

Apply 24 VDC power to 9 and 10 terminals on the D4P120A or apply 120

VAC on terminals named 120VAC. See Figure 7 and electrical specifications

for details.

[12.3] PERFORM DETECTOR CHECK

VERIFY STANDBY AND TROUBLE TEST per Table 3 on page 8. The use

of a remote accessory for visible indication of power and alarm is recom-

mended.

NOTE: If an instantaneous tamper delay is selected a trouble may be indi-

cated with the cover installed.

[12.4] SENSITIVITY VERIFICATION

The sensitivity of the sensor is confirmed to be operating within its allowable

range each time the sensor and power board LEDs blink green every 5 sec-

onds. Note in a maintenance condition the sensor LEDs will blink red every

5 seconds and power board will blink amber as depicted in

Table 3

on page

8. The maintenance condition indicates that the sensor is operating outside

its original factory preset sensitivity and shall be cleaned or replaced. See

Section 9 for reference. Also,the GEMINI model 501 aerosol generator can

be used for smoke entry testing. Set the generator to represent 4%/ft to 5%/ft

obscuration as described in the GEMINI 501 manual. Using the bowl shaped

applicator, apply aerosol until the panel alarms.

[12.5] DETECTOR CLEANING PROCEDURES

Notify the proper authorities that the smoke detector system is undergoing

maintenance, and that the system will temporarily be out of service. Disable

the zone or system undergoing maintenance to prevent unwanted signalling

and possible dispatch of the fire department.

[12.5.1] ALARM TESTS

1a. Test/Reset Button - Press and hold the test button located on the power

board cover for at least 2 seconds.

OR

1b. M02-04-00 Magnet Test - Place the painted surface of the magnet onto

the MAGNET TEST location on the sensor cover of unit (Figure 1).

OR

1c. Remote Test Accessory - See list on page 1.

The red alarm LED on the sensor and the power board should latch

on, as should any accessories (i.e. RA400ZA, RTS451). Verify system

control panel alarm status and control panel execution of all intended

auxiliary functions (i.e fan shutdown, damper control, etc.).

2. The detector must be reset by the system control panel, front cover Test/

Reset button, or remote accessory.

3. To reset using the Test/Reset button on the power board cover simply

Press and release.

4. Verify airflow test per Section 7 has been performed.

[12.5.2] SMOKE RESPONSE TESTS

To determine if smoke is capable of entering the sensing chamber, visually

identify any obstructions. Plug the exhaust and sampling tube holes to pre-

vent ducted air from carrying smoke away from the detector head, then blow

smoke such as cigarette, cotton wick, or punk directly at the head to cause an

alarm. REMEMBER TO REMOVE THE PLUGS AFTER THIS TEST, OR THE

DETECTOR WILL NOT FUNCTION PROPERLY.

[12.5.3] SMOKE ENTRY USING AEROSOL SMOKE

This test is intended for low-flow systems (100-500 FPM). If the air speed is

greater than 500 FPM, use a conventional manometer to measure differential

pressure between the sampling tubes, as described in Section 7.1.

Drill a

1

⁄

4

inch hole 3 feet upstream from the duct smoke detector. With the air

handler on, measure the air velocity with an anemometer. Air speed must be

at least 100 FPM. Spray aerosol smoke* into the duct through the

1

⁄

4

inch hole

for five seconds. Wait two minutes for the duct smoke detector to alarm. If the

duct smoke detector alarms, air is flowing through the detector. Remove the

duct smoke detector cover and blow out the residual aerosol smoke from the

chamber and reset the duct smoke detector. Use duct tape to seal the aerosol

smoke entry hole.

*Aerosol smoke can be purchased from Home Safeguard Industries, model

25S Smoke Detector Tester, Malibu, CA. Phone: 310/457-5813. When used

properly, the canned smoke agent will cause the smoke detector to go into