17/67 |

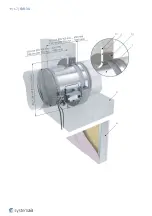

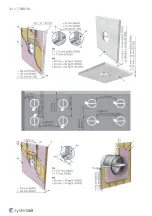

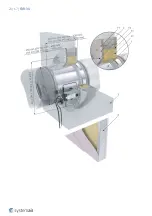

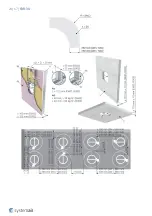

FDR-3G

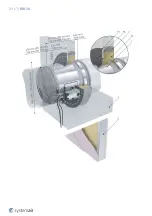

a)

- Flexible (plasterboard) wall

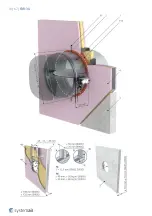

b)

- Concrete/masonry/cellular concrete (rigid) wall

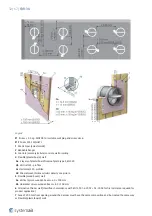

c)

- Concrete/cellular concrete (rigid) floor/ceiling

v

e

- Vertical wall

h

o

- Horizontal floor/ceiling

Installation, Maintenance & Operation

Some damper parts may have sharp edges – therefore to protect yourself from harm, please use gloves during damper

installation and manipulation. In order to prevent electric shock, fire or any other damage which could result from

incorrect damper usage and operation, it is important to:

1. ensure that installation is performed by a trained person.

2. follow the written and depicted instructions provided within Handbook closely.

3. perform damper inspection in accordance with Handbook.

4. check the damper’s functionality as per the chapter “Fire Damper Functionality Check” before you install the fire

damper. This procedure prevents the installation of a damper that has been damaged during transportation or

handling.

Information about installation, maintenance and operation is available in the “Handbook_FDR-3G” document or more

can be found at design.systemair.com.

Installation rules

• The duct connected to the fire damper must be supported or hung in such a way that the damper does not carry its

weight. The damper must not support any part of the surrounding construction or wall which could cause damage

and consequent damper failure. It is recommended to connect the damper to a dilatation compensator on either end

of the damper.

• The damper driving mechanism can be placed on either side of the wall, however it needs to be placed so as to

ensure easy access during inspection.

• According to the standard EN 1366-2, the distance between the fire damper bodies must be at least 200 mm. This

condition does not apply for tested distances. Therefore installations Wet and Soft are approved for smaller distances

under condition that the resulted resistivity is reduced to EI90S.

• The distance between the wall/ceiling and the fire damper must be at least 75 mm. This condition does not apply for

tested distances. Therefore installations Wet and Soft are approved for smaller distances under condition that the

resulted resistivity is reduced to EI90S.

• The fire damper must be installed into a fire partition structure in such a way that the damper blade in its closed

position is located inside this structure. A bendable hinge is provided on the damper body which represents a plane

where supporting constructure begins. This condition does not apply for installations On & Out.

• For each resistivity the minimum thickness of a its supporting construction cannot be decreased as per EN 1366-2 at

least 200 mm from the installation opening.

• The gap in the installation opening between the fire damper and the wall/ceiling can be increased by up to 50% of

the gap area, or decreased to the smallest amount possible that still provides sufficient space for the installation of

the filling.

IN ACCORDANCE WITH EN 15650, EACH FIRE DAMPER MUST BE INSTALLED ACCORDING TO THE INSTALLATION

INSTRUCTIONS PROVIDED BY THE MANUFACTURER!

Summary of Contents for 163262

Page 1: ...FDR 3G Circular Fire Damper Handbook ...

Page 19: ...19 67 FDR 3G ...

Page 20: ...20 67 FDR 3G ...

Page 23: ...23 67 FDR 3G ...

Page 24: ...24 67 FDR 3G ...

Page 27: ...27 67 FDR 3G ...

Page 28: ...28 67 FDR 3G ...

Page 31: ...31 67 FDR 3G ...

Page 33: ...33 67 FDR 3G Notes ve Vertical wall 1 Smaller distances maximum resistivity EI90 ve i o S ...

Page 35: ...35 67 FDR 3G ...

Page 36: ...36 67 FDR 3G ...

Page 39: ...39 67 FDR 3G ...

Page 40: ...40 67 FDR 3G ...

Page 67: ...Systemair DESIGN 2022 07 11 Handbook_FDR_3G_en GB Original instructions ...