18/67 |

FDR-3G

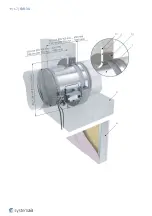

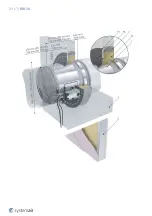

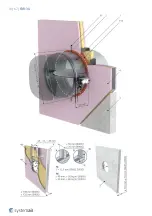

Wet Installation

Using Plaster/Mortar/Concrete Filling

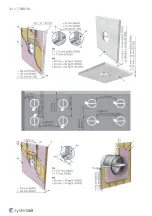

1. The supporting construction opening must be prepared as depicted. Opening surfaces must be even and cleaned off.

The flexible wall opening must be reinforced as per the standards for plasterboard walls. The opening dimensions are

driven by the nominal dimensions of the damper with added clearance. For circular dampers prepare the opening of

diameter D1.

2. Insert the closed damper into the middle of the opening so that the damper blade is in the wall. Use the bendable

hanger (2; or hangers) to secure the damper against the wall using a suitable screw (F1; recommended screwdiameter

5,5; e.g. DIN7981).

3.

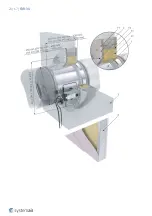

For damper diameter greater than 800 mm, it is recommended to use a duct support inside the damper to avoid

any damage, bend to the damper housing from the weight of the filling.

4. Fill in the area between the wall and the damper with plaster or mortar or concrete filling (2), while paying attention

to prevent the fouling of the damper’s functional parts, which could limit its correct functionality. The best way is to

cover the functional parts during installation. The seepage of the filling material can be prevented by using boards.

However, these are not required for wet installation.

First let the plaster or mortar or concrete filling harden and then perform the next steps!

5. After the filling hardens, remove the duct support from inside of the damper.

6. If needed, uncover and clean the damper after installation.

7. Check the damper’s functionality

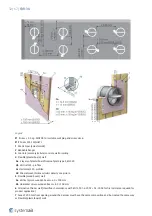

Installation - Standard Distances

According to the standard EN 1366-2, the minimum distance from the wall or ceiling to the damper body is 75 mm.

For multiple crossings through a fire-resistive wall the minimum distance between two damper bodies is 200 mm. This

applies to distances between the damper and a nearby foreign object crossing the fire-resistive wall.

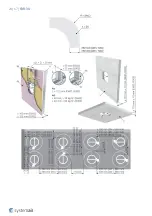

Installation - Smaller Distances - Maximum resistivity reduced to EI90S

The distance between 2 individual fire dampers can be reduced to 60 mm, measured from surface to surface of the

housing and the distance between the surface of the damper installed in the duct and the adjacent supporting

construction (wall/floor) can be reduced to 40 mm, provided that the fire resistance classification will be reduced as

follows: EI90 (ve i <-> o) S.

Installation in a Wall thinner than tested

Installation in a thinner wall is allowed under the condition that an additional layer/layers of fire protective board are

fixed to the surface of the wall in order to achieve the same length of damper penetration seal as was tested. The

minimum width of added boards around the damper is 200 mm. In addition, the alternative thinner wall should be

classified in accordance with EN 13501-2:2007 + A1: 2009 for fire-resistance required for product application. For a

protruding wall, the additional layers must be fixed on the steel supporting construction of the wall.

1 Wet

FDR-3G

DN100 ... DN1000

EI 60 (v

e

h

o

i ↔ o) S

a)

b)

c)

360°

EI 90 (v

e

h

o

i ↔ o) S

EI 120 (v

e

h

o

i ↔ o) S

Summary of Contents for 163262

Page 1: ...FDR 3G Circular Fire Damper Handbook ...

Page 19: ...19 67 FDR 3G ...

Page 20: ...20 67 FDR 3G ...

Page 23: ...23 67 FDR 3G ...

Page 24: ...24 67 FDR 3G ...

Page 27: ...27 67 FDR 3G ...

Page 28: ...28 67 FDR 3G ...

Page 31: ...31 67 FDR 3G ...

Page 33: ...33 67 FDR 3G Notes ve Vertical wall 1 Smaller distances maximum resistivity EI90 ve i o S ...

Page 35: ...35 67 FDR 3G ...

Page 36: ...36 67 FDR 3G ...

Page 39: ...39 67 FDR 3G ...

Page 40: ...40 67 FDR 3G ...

Page 67: ...Systemair DESIGN 2022 07 11 Handbook_FDR_3G_en GB Original instructions ...