29/67 |

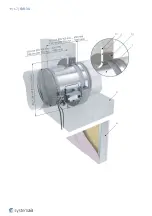

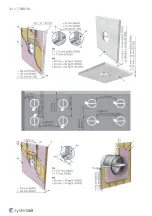

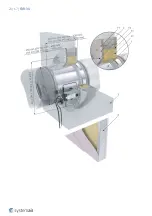

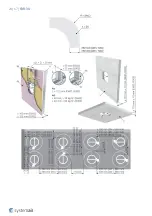

FDR-3G

Legend

F1

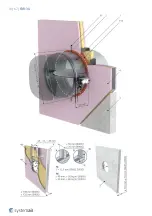

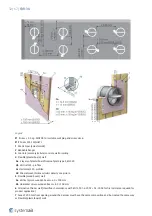

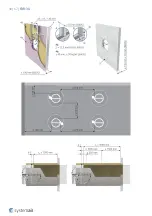

Screw ≥ 5,5 DIN7981 or suitable wall plug and screw size 6.

F5

Mineral wool segment (minimum 150 kg/m3).

F6

Layer of fire resistive coating (Promastop-CC/Promat) at least 2 mm thick for exposed surfaces.

1

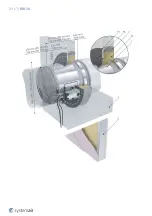

Fire damper (actuator side)

2

Bendable hanger

3

Concrete/masonry/cellular concrete wall or ceiling

4

Flexible (plasterboard) wall

4a

2 layers of plasterboard fireproof plate type F, EN 520

4b

Vertical CW – profiles

4c

Horizontal CW – profiles

4d

Mineral wool; thickness/cubic density see picture.

5

Flexible (wood beam) wall

5a

Vertical spruce wooden beam ≥ 60 × 100 mm

5b

Horizontal spruce wooden beam ≥ 80 × 100 mm

6

Alternative thinner wall (classified in accordance with EN 13501-2:2007 + A1: 2009 for fire resistance required for

product application)

7

Area of 200 mm from opening around the damper must have the same composition and be created the same way

as Flexible (plasterboard) wall.

Notes:

ve

Vertical (wall)

ho

Horizontal (floor/ceiling)

Summary of Contents for 163262

Page 1: ...FDR 3G Circular Fire Damper Handbook ...

Page 19: ...19 67 FDR 3G ...

Page 20: ...20 67 FDR 3G ...

Page 23: ...23 67 FDR 3G ...

Page 24: ...24 67 FDR 3G ...

Page 27: ...27 67 FDR 3G ...

Page 28: ...28 67 FDR 3G ...

Page 31: ...31 67 FDR 3G ...

Page 33: ...33 67 FDR 3G Notes ve Vertical wall 1 Smaller distances maximum resistivity EI90 ve i o S ...

Page 35: ...35 67 FDR 3G ...

Page 36: ...36 67 FDR 3G ...

Page 39: ...39 67 FDR 3G ...

Page 40: ...40 67 FDR 3G ...

Page 67: ...Systemair DESIGN 2022 07 11 Handbook_FDR_3G_en GB Original instructions ...