14/46 |

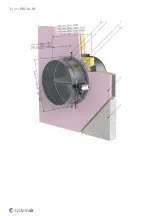

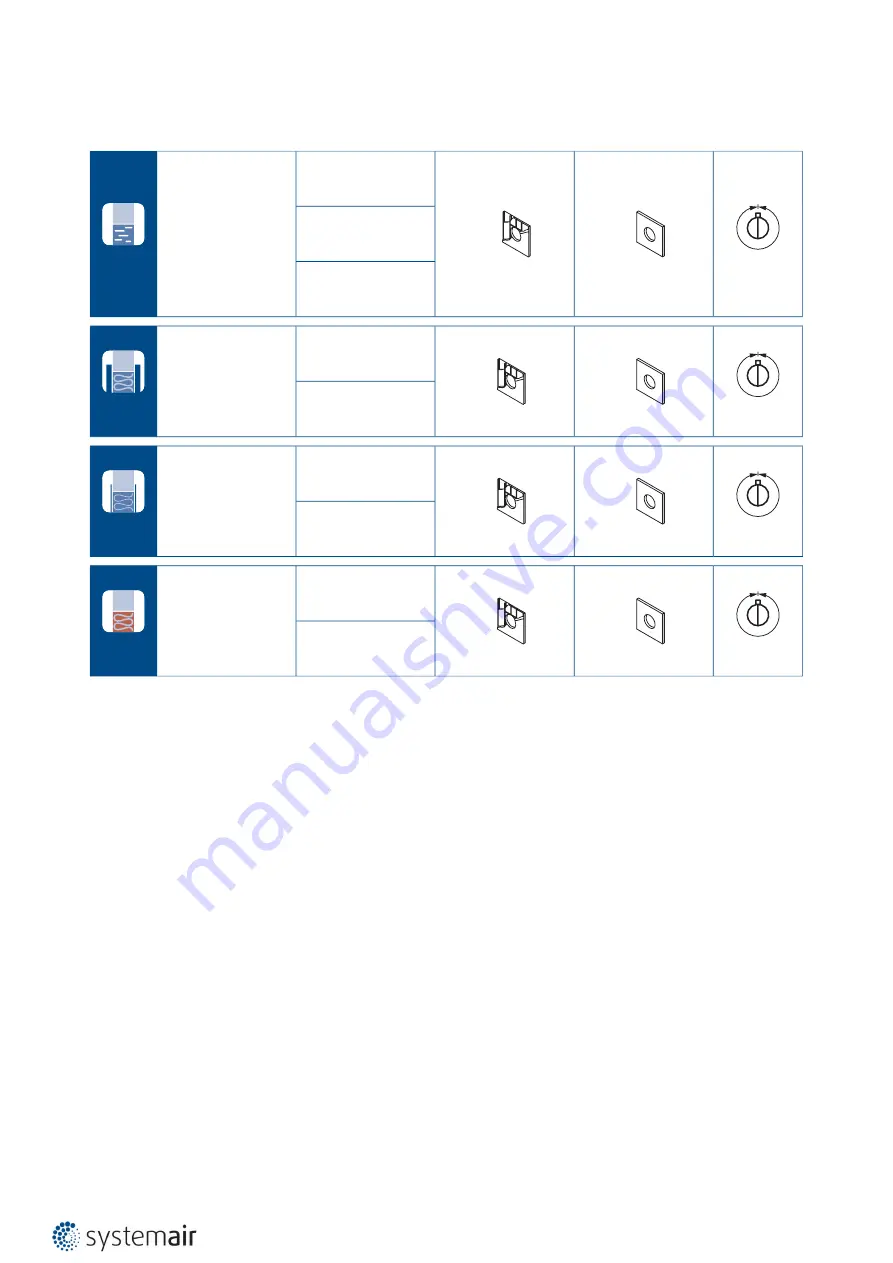

FDR-3G…OF

Installation Methods

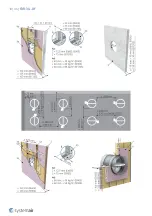

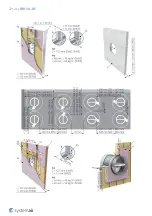

1 Wet

FDR-3G...OF

DN200 ... DN630

EI 60 (v

e

i ↔ o) S

a)

b)

360°

EI 90 (v

e

i ↔ o) S

EI 120 (v

e

i ↔ o) S

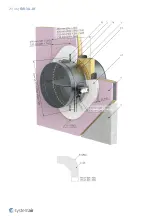

2 Dry

FDR-3G...OF

DN200 ... DN630

EI 60 (v

e

i ↔ o) S

a)

b)

360°

EI 90 (v

e

i ↔ o) S

3 Soft

FDR-3G...OF

DN200 ... DN630

EI 60 (v

e

i ↔ o) S

a)

b)

360°

EI 90 (v

e

i ↔ o) S

3H Hilti

FDR-3G...OF

DN200 ... DN630

EI 60 (v

e

- i ↔ o) S

a)

b)

360°

EI 90 (v

e

- i ↔ o) S

Note:

Installations of subtype

FDR-3G...OF

were tested without connected duct, with natural convection.

Legend:

1. Wet

- Wet Installation, Using Plaster/Mortar/Concrete Filling

2. Dry

- Dry Installation, using cover boards and mineral wool filing

3. Soft

- Soft Installation, using mineral wool filing

3H. Hilti

- Filling made only from Hilti foam

a)

- Flexible (plasterboard) wall

b)

- Concrete/masonry/cellular concrete (rigid) wall

v

e

- Vertical wall

Installation, Maintenance & Operation

Some damper parts may have sharp edges – therefore to protect yourself from harm, please use gloves during damper

installation and manipulation. In order to prevent electric shock, fire or any other damage which could result from

incorrect damper usage and operation, it is important to:

1. ensure that installation is performed by a trained person.

2. follow the written and depicted instructions provided within Handbook closely.

3. perform damper inspection in accordance with Handbook.

Summary of Contents for A-FDR-3G-OF

Page 1: ...FDR 3G OF Overflow Fire Damper FDR 3G...

Page 13: ...13 46 FDR 3G OF 250 DN 630 Standardardly in position B On demand in position L T...

Page 17: ...17 46 FDR 3G OF...

Page 18: ...18 46 FDR 3G OF...

Page 21: ...21 46 FDR 3G OF...

Page 22: ...22 46 FDR 3G OF...

Page 25: ...25 46 FDR 3G OF...

Page 26: ...26 46 FDR 3G OF...

Page 29: ...29 46 FDR 3G OF...

Page 30: ...30 46 FDR 3G OF...

Page 46: ...Systemair DESIGN 2021 04 27 Handbook_FDR_3G_OF_en GB...