6/48 |

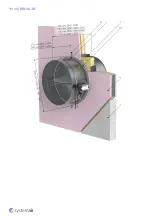

FDR-3G…OF

Technical Parameters

Durability test

50 cycles/manually operated activation mechanism – with no change of the required properties

10000 + 100 + 100 cycles/actuator operated activation mechanism – with no change of the required properties

Fire testing pressure

Underpressure up to 300 Pa

Safety position

Closed. (In fire scenario the damper closes via spring in actuator or spring in manual mechanism)

Airflow direction

Both directions

Allowed air velocity

Damper can still operate at max. 12 m/s. Air without any mechanical or chemical contamination

Side with fire protection

Depending on installation classification: From both sides (i <-> o)

Repeated opening

Suitable for daily check procedure. It is not possible to operate the device after reaching Activation temperature.

Activation Temperature

Manually operated: 74 °C as standard by means of a spring after the melting of the thermofuse and/or after smoke

sensor detection.

Actuator operated: 72 °C as standard by means of the spring after current interruption in the electro-thermal fuse and/

or after smoke sensor detection.

Operational temperature

Minimum: 0 °C

Maximum: 60 °C for 74 °C and 72 °C thermofuse

Environment suitability

Protected against weather disruptions, with temperature above 0 °C, up to 95% Rha, (3K5 according to EN 60721-3-3)

Open/Closed indication

Manually operated microswitches - Activation types H2-OF up to H6-2-OF

Actuator operated built-in microswitches - Activation types B230T-OF/G230T-OF up to BSD24T-OF/GSD24T-OF

Closing/Opening time

Manually operated < 10 s, actuator operated < 20 s

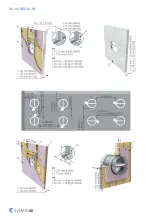

Inspection possibility

By opening of the inspection lid. For smaller than DN160 after removing of the activation mechanism, or a inspection

opening must be added to the connecting duct. Smoke senzor can be tested with test button or through damper grille

with smoke spray tester.

Maintenance

Not required. Dry cleaning if demanded by law in the country in which the dampers are installed.

Revisions

Determined by law in the country in which the fire dampers are installed but at least every 12 months.

Allowed pressure

1200 Pa

Summary of Contents for FDR-3G

Page 1: ...FDR 3G OF Overflow Fire Damper FDR 3G ...

Page 5: ...5 48 FDR 3G OF AM FD Activation Mechanisms CBR FD Cover Boards ...

Page 9: ...9 48 FDR 3G OF P15 Grid P16 Extended ductwork ...

Page 13: ...13 48 FDR 3G OF Dimensions Free area Dimensions Note 3 Inclusive bearing Overhangs Weights ...

Page 15: ...15 48 FDR 3G OF ø 250 DN ø630 Standardardly in position B On demand in position L T ...

Page 19: ...19 48 FDR 3G OF ...

Page 20: ...20 48 FDR 3G OF ...

Page 23: ...23 48 FDR 3G OF ...

Page 24: ...24 48 FDR 3G OF ...

Page 27: ...27 48 FDR 3G OF ...

Page 28: ...28 48 FDR 3G OF ...

Page 31: ...31 48 FDR 3G OF ...

Page 32: ...32 48 FDR 3G OF ...

Page 48: ...Systemair DESIGN 2020 10 23 HandBook_FDR_3G_OF_en GB 8519DCD0 0720 11EB DCA1 21ABDD8D93BC ...