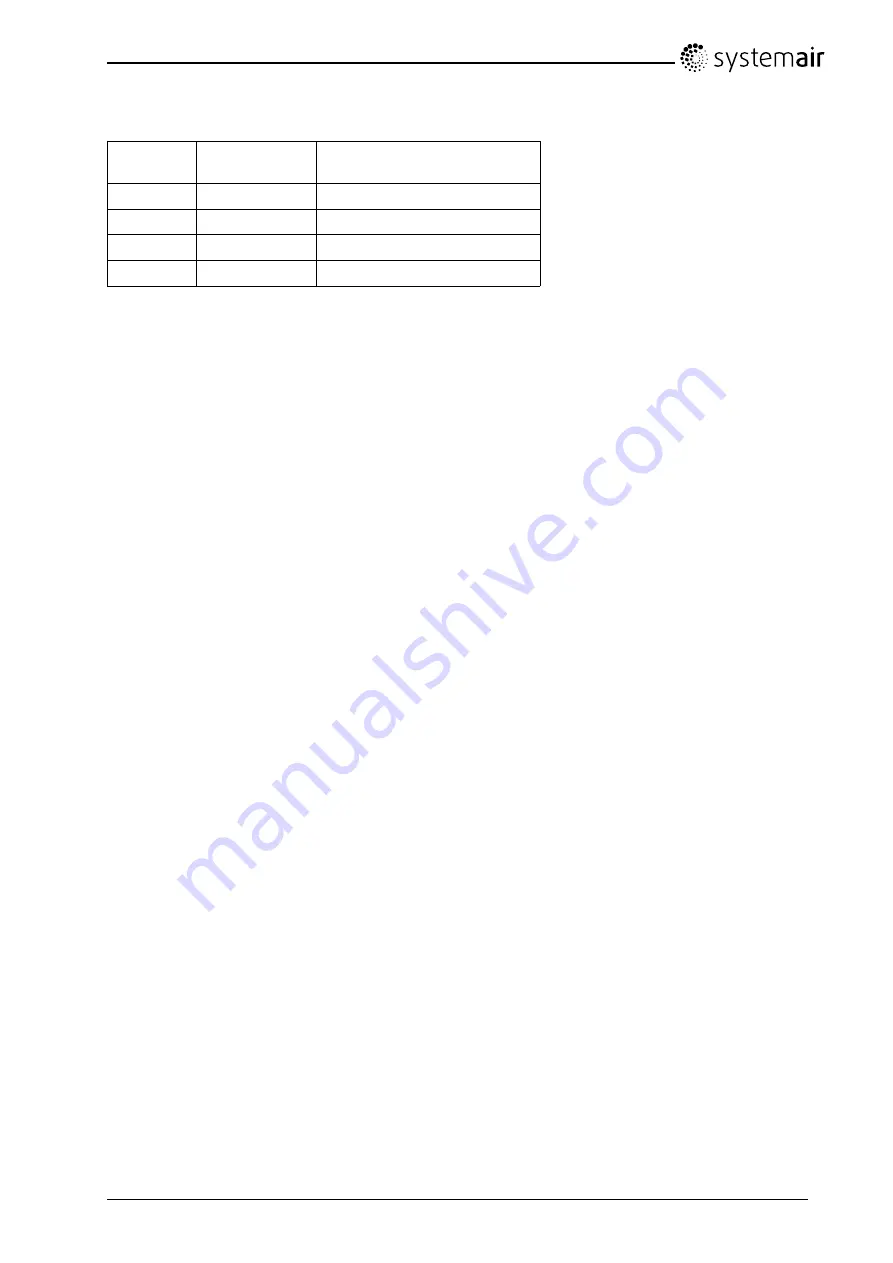

5.3.2.1 Supported filter types

Unit

model

Filter class

Dimensions

15

M5

490x392x520

20

M5

490x490x520

20

M5

592x490x520

25

M5

592x592x520

Optionally, F7 class filters can be used instead of M5 for extract air filtering.

5.3.3 Checking the brine coil

The brine coil is used to absorb heat from extracted air. The coil will have reduced capacity if dust forms a

coating on the coil surface and increases the pressure drop on the air side. Even if the Living HR is fitted

with the extract air filters, dust eventually will deposit on the coil fins.

5.3.3.1 Inspection

• Check the coil fins for any damage;

• Check if heat transfer agent is not leaking;

• Check the dip dray and drain, clean if necessary;

5.3.3.2 Cleaning

• Use the vacuum cleaner to remove dust from the inlet side of you can blow them with compressed

air from the outlet side;

• Use hot water mixed with non corrosive cleaning medium and rinse using water. Any corrosion should

be cleaned off immediately and the surface treated.

5.3.4 Checking the damper

A faulty damper can give rise to disturbances that may result in serious problems. Make sure to check all

three dampers.

• Check operation of the damper actuator.

• Check that the damper tightens when closed. If not, adjust the damper actuator to make the damper

tight (does not apply to trim dampers).

• Check the sealing strips.

• If the damper does not operate, check that nothing is stuck between the drive mechanism and damper

blades to interfere with the damper function.

Clean the damper blades with a cloth. If they are severely fouled, an environmentally friendly

degreasing agent can be used.

5.3.5 Additional maintenance

Living HR does not require any maintenance other than the annual service. However things to be checked

in addition could include:

• Tightening of clamps in the cabinet.

• Measuring power consumption.

• Reviewing settings and set points.

Living HR

Operation and Maintenance Instructions

209534

16

Systemair AB