PKIR, PKIS

| PP-28_201612 | 15 / 48

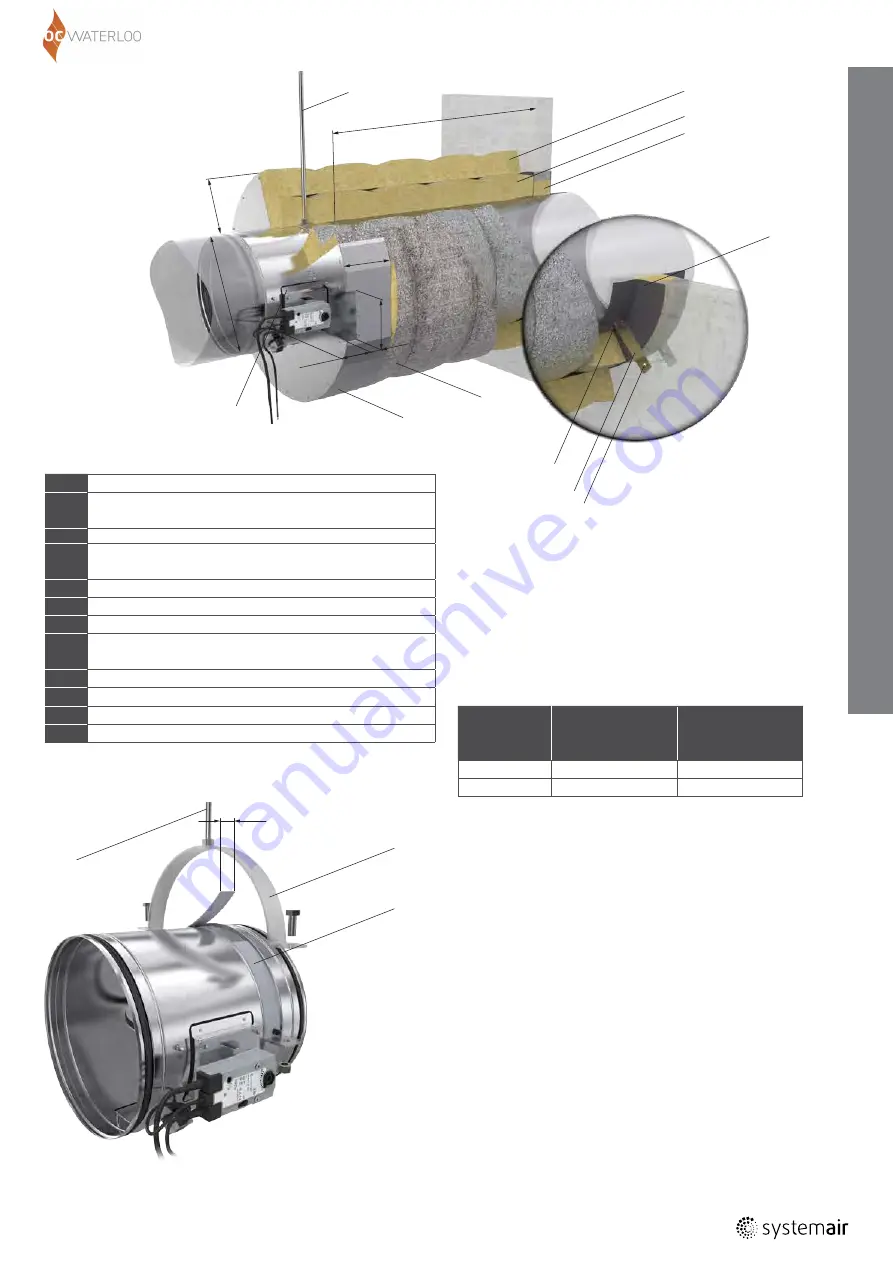

Fig. 14:

Installation

of a round fire damper PKIR3G

100 ≤

DN

≤ 630 mm

on a wall

and

out of a wall

NOTE: This picture is valid for

L

D

= max. 1500 mm from

the damper’s ending. For

L

D

> 1500 mm the maximum

spacing between threaded rods must be 1500 mm and

one more point of suspension must be added in the

position of damper blade as close as possible to the end

of the damper.

Wall and

opening type

Dimensions of the

openings ø

D

1

(mm)

Dimensions of the

internal frame

□

D

2

(mm)

RRW

ø

DN

+120

-

FRW

ø

DN

+120

□

DN

+120

Tab. 20: Wall opening

NOTE:

øD

1

, W

1

, H

1

see Fig. 1 - 4

1

Steel threaded rod M12

2

Sheet metal ringlet for damper suspension

(e.g. MP-MX/HILTI)

3

Ceramic tape (e.g. A-KERA) width 40 mm, thickness 2 mm

4

Sheet metal belt 40

×

2 mm bent into a shape L

with sides 35 and 160 mm

5

Screw 5,5 DIN7981

6

Screw 3,9 × max. 13 DIN7504

7

Mineral wool (66 kg/m

3

) - in a wall

8

Layer of fire resistive mastic (e.g. Intumex AC)

at least 2 mm thick

9

Mineral wool (66 kg/m

3

) - inner layer

10

Mineral wool (66 kg/m

3

) - outer layer

11

Steel binding wire thickness 1,6 mm

12

Insulation front cover*

Legend

* Accessory IPOR-PKI (see TPI-28)

1.5.1

ON

A W

ALL

&

1.6.1

OUT

OF

A W

ALL

- Miner

al

w

ool - EI90S

8

9

7

12

11

18

0

150

6

4

5

1

10

6

ø

DN

170

40

15

5

L

D

2

3

40

PKIR3G

1