PKIR, PKIS

| PP-28_201612 | 19 / 48

1.5.2

ON

A W

ALL

&

1.6.2

OUT

OF

A W

ALL

- Miner

al

w

ool - EI60S

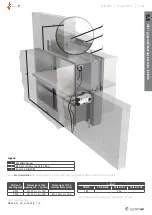

Fig. 15ba:

Installation

of a rectangular fire damper

PKIS3G

on a wall

and

out of a wall

- fire resistivity EI60S

NOTES: This picture is valid for

L

D

= max. 1500 mm from

the damper’s ending. For

L

D

> 1500 mm the maximum

spacing between threaded rods must be max. 1500 mm

and one more point of suspension must be added as

close as possible to the connection flange.

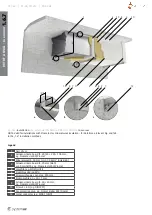

L

D

80

H

W

6

5

4

3

1

2

8

L

S

5

7

9

Wall and

opening type

Dimensions

of the openings

W

1

×

H

1

(mm)

Dimensions

of the internal

frame (mm)

RSW

W

+ 120 ×

H

+ 120

-

FSW

W

+ 120 ×

H

+ 120

W

+ 120 ×

H

+ 120

1

Steel threaded rod M10

2

U-profile (e.g. MQ31/HILTI) Top & Bottom

3

Mineral wool (66 kg/m

3

)

4

Layer of fire resistive mastic (e.g. ISOVER Protect BSF)

on both side at least 2 mm thick

5

Layer of fire resistive glue (e.g. ISOVER Protect BSK)

6

Mineral wool th. 80 mm (min. 66 kg/m

3

;

e.g. ISOVER Ultimate U-Protect Slab 4.0 Alu1)

7

Welding pin – length 80 mm *

8

Stiffening rods: horizontal for

W

> 600 mm;

vertical for

H

> 400 mm. **

9

Aluminium tape around the front side

and on places uncovered with aluminium foil

Legend

Tab. 22b: Wall opening

NOTE:

øD

1

, W

1

, H

1

see Fig. 1 - 4

* Top without welding pins, side 20 pins/m

2

,

bottom 20 pins/m

2

; distance between pins max. 260 mm,

distance of the pin from the edge 80 mm

** Along the insulated duct - the first stiffening rod is placed

inside the wall. Each subsequent stiffening rod must be placed

with an

L

S

distance = max. 1000 mm. The last stiffening rod must

be placed 1000 mm from the fire damper flange at most. If the

fire damper flange is closer to the wall than the overhang of the

open blade (

R

2

; see Tab. In TechSpec_TPI-28...), then move the

first stiffening rod to the right so that the distance between the

stiffening rod and the fire damper flange is

R

2

+ 50 mm.