PKIR-E60S & EKIR-E60S

| PP-87_201701 | 3 / 8

1 Installation manual

•

All connecting ducts to the fire damper must be supported or

suspended in such a way that the duct weight would not lean

on the damper. Furthermore the damper should not bear any

weight from the above or surrounding construction; this can

result in distortion of the casing and ultimately malfunctioning

of the fire damper.

•

The damper actuator can be located on any side of the fire

resistant wall, however it must be positioned in such a way

that there is easy access provided for inspection or service.

•

Spacing between the dampers must be a minimum of 200

mm.

•

Space between the wall/ceiling and the damper must be at

least 75 mm.

•

All dampers can be installed with the blade in a horizontal or

vertical position.

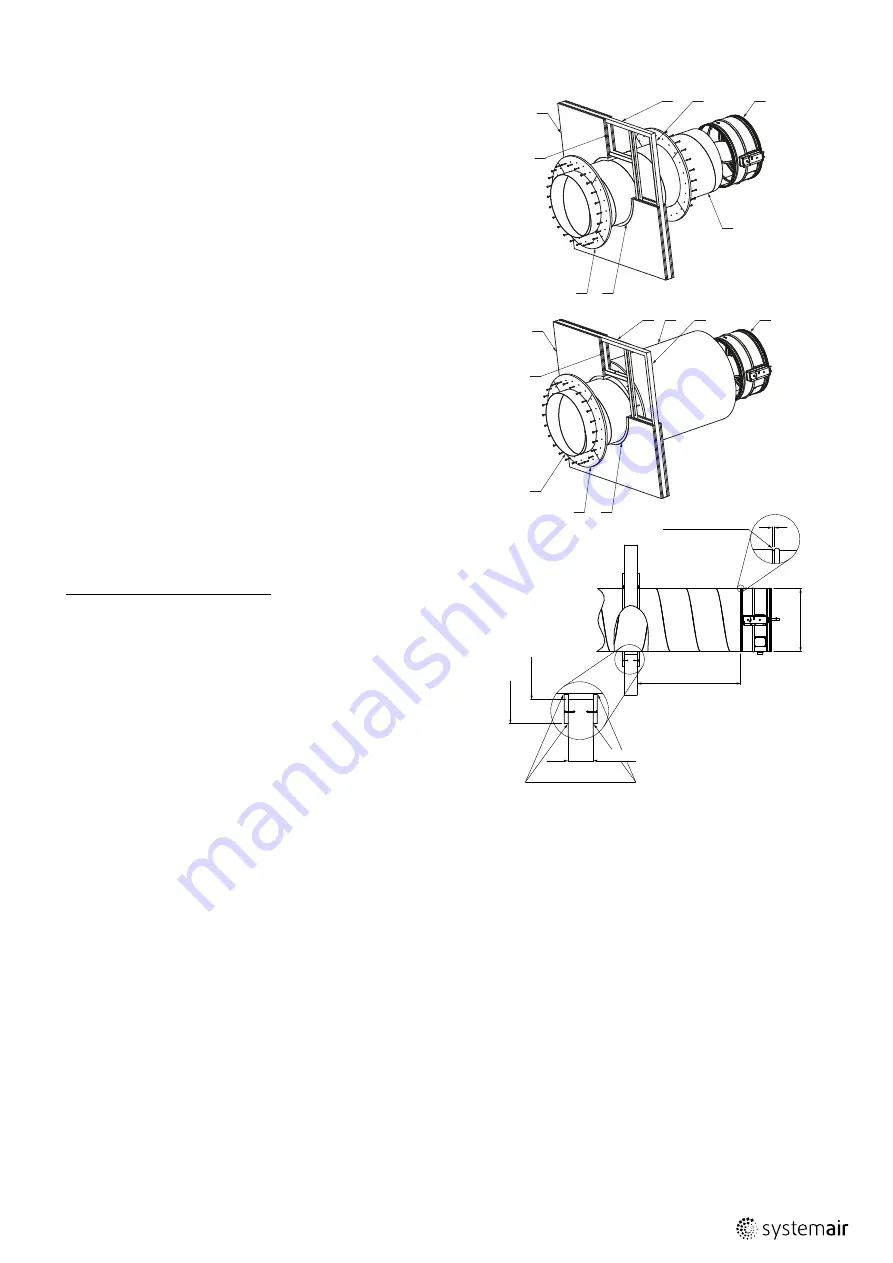

Fig.1: Vertical installation of the PKIR-E60S and EKIR-E60S

3

1

7

8

4

2

5

6

1.1 Vertical installation of the PKIR-EI60S

(in a horizontal duct – Fig.1)

1. Insert the fire damper into the duct - the sealing spiro safe

must be wholy in the duct and the end of the fire damper

has to be ca 5 mm away from the ridge (to allow for thermal

dilatations). The distance between the end of the damper and

the wall can be

L

= 0 – 1500 mm.

2. Seal both gaps between ends of the damper and the duct

with fire resistant mastic – e.g. Intumex AN.

3. The duct can be installed into the wall by either wet or dry

method (on the figure 1 there is only dry method), equally

as by fire dampers installed into the wall (see the document

InstalMaintenOperInstr_PP-28_EN)

4. Check the damper functionality. (See Operating manual)

Damper Parts Description:

1. PKIR-E60S

2. Cover plate

3. Metal duct

4. Mineral wool

5. Flexible or rigid wall

6. Mineral wool

7. Horizontal profile UW (if flexible wall)

8. Vertical profile (if flexible wall)

9. Insulation with the same fire resistivity as the fire damper and

the wall ceiling have

125 min.

5

to seal (Intumex AN)

ØD

0-1500

mastic (Intumex AN)

ØD+60

ØD+X

2

5

3

4

1

6

8

7

9