8 / 8 | PP-87_201701 | PKIR-E60S & EKIR-E60S

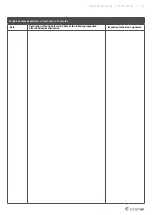

Warranty Service

12

1396

IMOS-Systemair

90043 Kalinkovo 371, Slovakia

1396 - CPD - 0069 EN 15650 : 2010

Fire damper:

- all types of PKI-R-E60S

Nominal activation conditions/sensitivity:

Pass

- sensing element load bearing capacity

- sensing element response temperature

Response delay (resp. time)

Pass

- closure time

Operational reliability:

- cycling

10200 cycles - pass

Fire resistance:

- maintenance of the cross section (under E)

- integrity E

E60 (ve ho i↔o)S

- insulation I

- smoke leakage S

- mechanical stability (under E)

- cross section (under E)

Durability of response delay:

- sensing element response temperature

and load bearing capacity

Pass

Durability of operational reliability:

- open and closing cycle

Pass

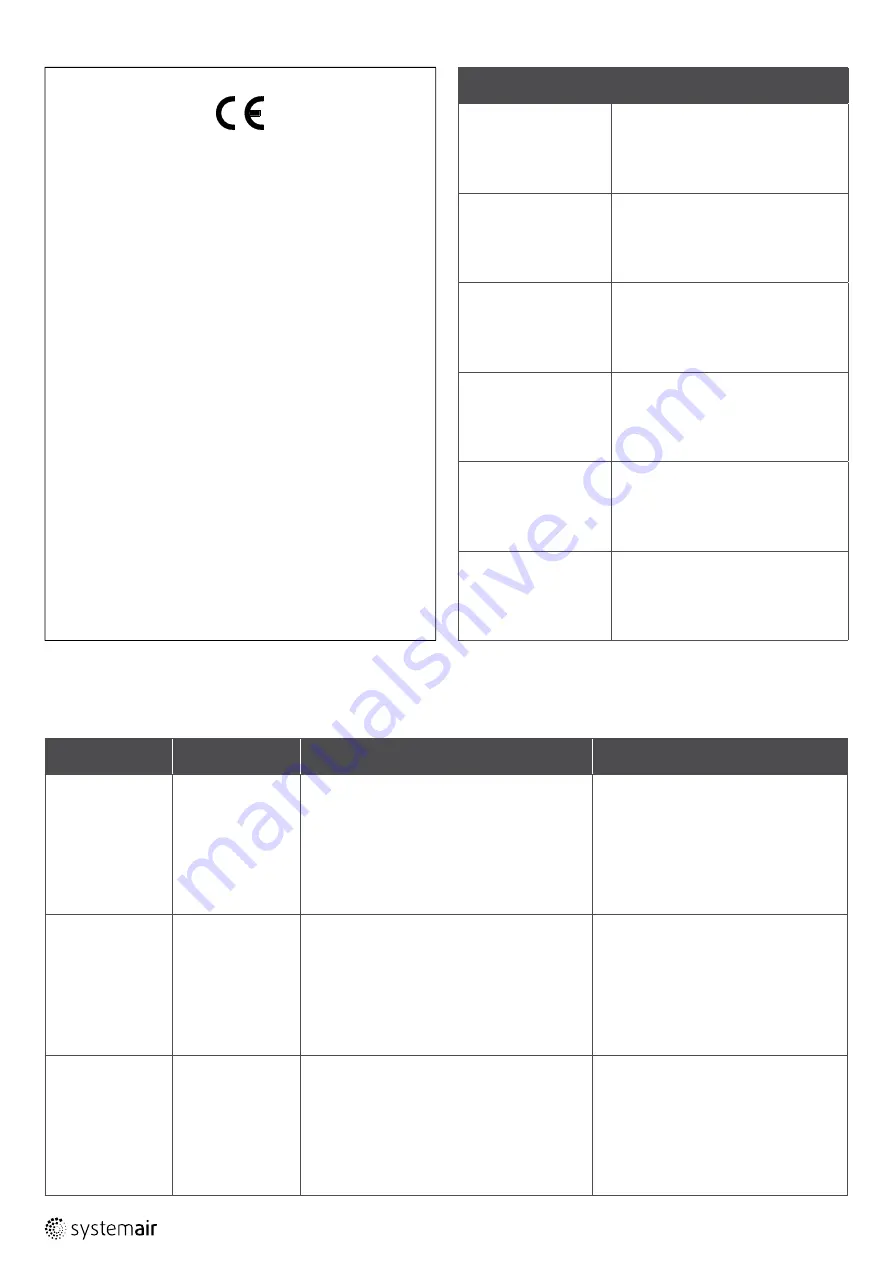

Damper Identification

Building object

Emplacement

Room no.

Position no.

Identification

Signalization

Date of warranty

repair notification

Date of warranty

repair finalization

Description of the executed warranty repair

Representative of the manufacturer

(stamp, signature)