10

Note:

The list “COMPATIBILITY WITH CHEMICAL AGENTS” is available in our online catalogue. This list has been

produced to the best of our knowledge, all statements without guarantee for correctness. Examination of

the media to be transported is a matter for the plant operator. Here, it is merely a question of a

recommendation.

6.4

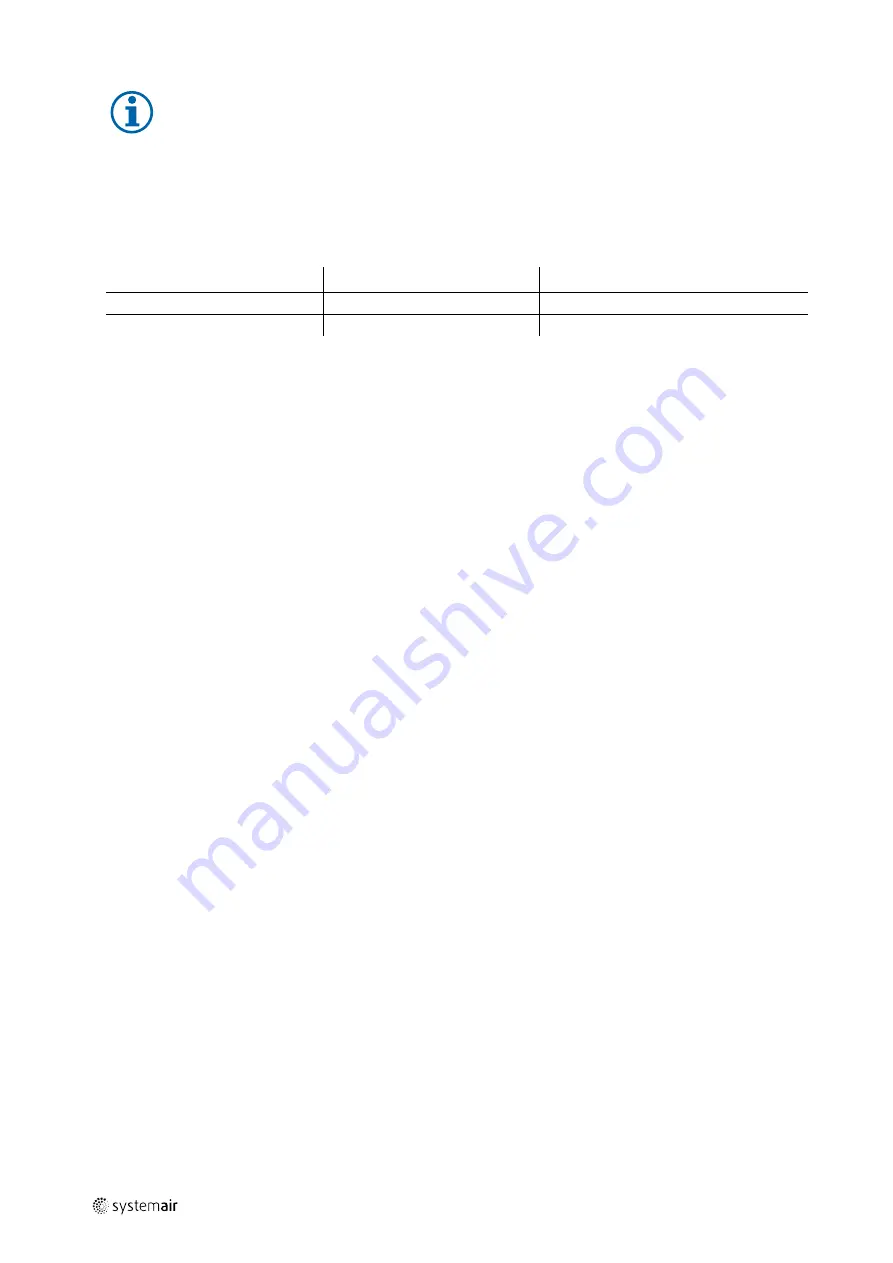

Minumum air gap

The following table shows the minimum air gap between the rotor and the housing.

Size

minimum air gap [mm]

Size

minimum air gap [mm]

Size

minimum air gap [mm]

125

2.00

180

3.0

250

4.5

160

2.50

200

3.5

6.5

Intended use

Indended use PRF and PRF EX

• The fans are intended for installation in ventilation systems.

• The fans are exclusively intended for extract air applications.

• The fans have been developed and built to convey air with the simultaneous presence of corrosive gases/vapours.

Indended use PRF EX

• The EX fans are not ready-for-use products, but have been designed as components for ventilation equipment, ma-

chines and systems. They may only be operated when they have been installed in accordance with their use and

safety has been ensured by protective devices pursuant to DIN EN 294 (DIN EN ISO 12100-1).

• The fans are only intended for conveying air or explosion-capable atmospheres of Zone 1, Category 2G, and Zone 2,

Category 3G.

• The maximum permissible operating data on the name plate apply for an air density of 1.2 kg/m³ (sea level) and a

max. air humidity of 80%.

6.6

Incorrect use

Incorrect use refers mainly to using the fan in another way to that described. The following examples are incorrect

and hazardous:

Incorrect use PRF and PRF EX

• Conveying of abrasive, combustible air or air with

solid particles.

• Conveying media which attack the materials of the

fan (housing, rotor and slip rings of polypropylene).

• Operation without duct system or protection grille

• Operation with the air connections closed

Incorrect use PRF

• Conveying of explosive and combustible media

Incorrect use PRF EX

• The fans are not suited to intake of media containing

dust or with a such a dust content that depositing on

the blades and on the housing of the fan may

influence the operation and the explosion protection

of the fan. If there is the risk of such deposits,

matching waste air cleaning must be carried out.

| 002