9

6

Description

• Material of the housing: UV resistant PE (PRF-EX from PP)

• Material of the impeller: PP

Warning

• Examined according to ATEX directive 2014/34/EU

• Antistatic housing

The explosion-protected fans can be used for temperature classes T1 to T4 and have been registered for

conveying explosion-capable atmosphere in Zone 1 and 2, category 2G and 3G, with the groups IIA, IIB and

IIC (only PRF-EX Ex d).

PRF-EX Ex d possess an IEC norm motor in an Ex d finish which can be controlled via a frequency inverter

and has an added-on terminal box in Ex e finish. Motor protection by integrated PTC resistor with connection

to a motor protection switching device e.g. U-EK230E.

6.1

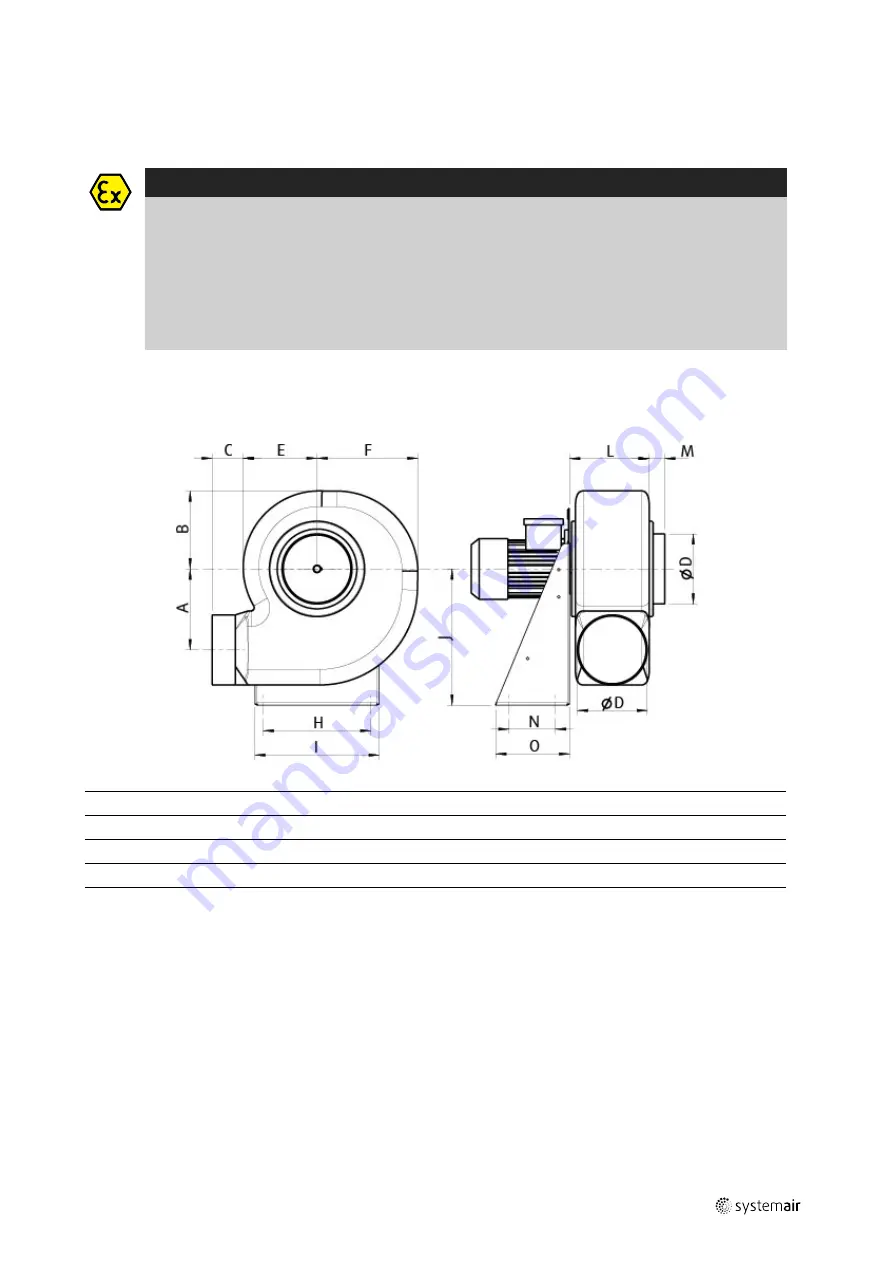

Dimension

Table 2 Dimensions

[mm]

A

B

C

ØD

E

F

H

I

J

L

M

N

O

PRF, PRF EX 125

142

165

60

125

150

183

200

235

250

115

40

100

140

PRF, PRF EX 160

182

210

80

160

190

237

255

290

310

150

40

100

140

PRF, PRF EX 180

205

230

80

180

205

275

277

320

350

160

40

120

190

PRF, PRF EX 200

227

245

80

200

220

313

320

355

410

170

40

150

230

PRF, PRF EX 250

284

330

80

250

270

380

330

370

495

195

40

170

250

6.2

Fan and motor data

• Max. temperature of transported air, max. ambient temperature, sound pressure –> see data sheet, available in our

online catalogue.

• Voltage, current, enclosure class, weight –> see name plate

• The motor data can be found on the name plate of the motor, or in the technical documents of the motor

manufacturer.

6.3

Chemical components

The standard variants of the plastic used are polyethylene (PE) and polypropylene (PP). As a matter of principle, the ro-

tor material is the indicator for the selection.

| 002