Dry

18/48 | User Manual S-BM2 | 202010

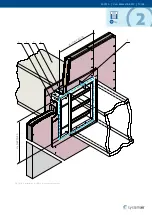

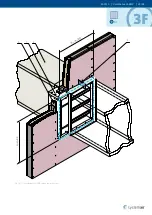

Dry Installation

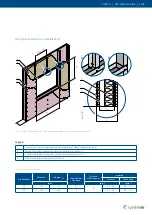

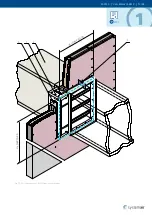

Wall Installation Using Mineral Wool and Cover Boards

1. The supporting construction opening must be prepared in a way depicted in the “Opening Preparation for

S-BM2 Installation” section (as per Fig. 1 and Fig. 2). Opening surfaces must be even and cleaned off.

The flexible wall opening must be reinforced as per the standards for plasterboard walls.

The opening dimensions are driven by the nominal dimensions of the damper with added clearance.

The opening will be with the dimensions of

W

1

and

H

1

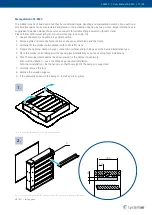

2. Insert the damper as per the “Manipulation of S-BM2” section into the middle of the opening so that the damper

blade is in the wall. For damper widths greater than 600 mm, it is recommended to use a duct support inside

the damper during installation to avoid any damage caused to the damper housing by the weight of the filling.

3. Fill in the area between the wall and the damper with mineral wool (3) with a density of at least 100 kg/m

3

thoroughly but in such a way that will not deform the duct.

4. Close the gap between the damper and the mounting opening, use gypsum boards (7) with screws (8)

which fix the gypsum boards to wall.

5. All the gaps between gypsum boards and the wall and between gypsum boards and the connected ductwork

made of Promatect boards need to be filled with putty for gypsum boards (9; e.g. Rigips Super)

6. Check the functionality of the damper.

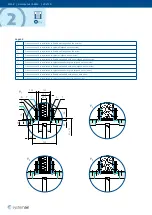

Dimension

Range

(mm)

Classification

Supporting

Construction

Construction Type/Minimal Thickness (mm)

Allowed

Blade Axis

Orientation

Dry

200 × 425

up to

1000 × 1225

EI90 (v

ew

i ↔ o) S1000 C

mod

MAmulti

Wall

Rigid/125

Flexible/125

EI90 (h

ow

i ↔ o) S1000 C

mod

MAmulti

Floor/ceiling

-

EI120 (v

ew

i ↔ o) S1000 C

mod

MAmulti

Wall

Rigid/125

Flexible/125

EI120 (h

ow

i ↔ o) S1000 C

mod

MAmulti

Floor/ceiling

-

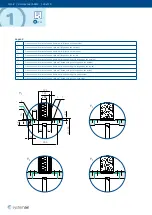

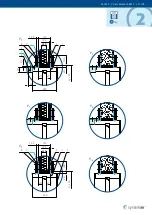

Legend for figures of

Dry installation

1

Smoke control damper S-BM2

2

Connected ductwork made of Promatect-L500 boards (min. 500 kg/m

3

, Promat)

3

Mineral wool filling (min. 100 kg/m³)

4

Grille

5

Nails or pins per ductwork manufacturer instructions

6

Fire resistive coating Promat K84 (Promat)

7

Gypsum boards

8

Screws for fixing gypsum boards to: flexible wall (TN 3,5×35)/rigid wall (HUS-CR 8×65)

9

Putty for gypsum boards, e.g. Rigips Super

Y

Cutting plane

Horizontal blade axis orientation of the damper

Vertical blade axis orientation of the damper