30/48 | User Manual S-BM2 | 202010

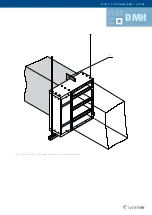

DMH

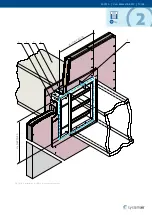

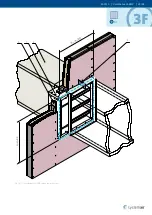

Installation in the Duct Made of Sheet Metal

S-BM2 smoke control damper can be installed on “single” (tested according to EN 1366-9) or “multi” (tested according

to EN 1366-8) ductwork. If mounted on a duct classified with lover fire resistivity, the fire resistivity of S-BM2 smoke

control damper will be decreased to the duct level. This section does not depict duct hanger rules as those are

dependent on the weight of the duct itself and must be statically approved. Smoke control dampers must be suspended

from solid ceiling slabs using adequately sized threaded rods. When using anchors in the ceiling, use fire rated anchor

(with suitable fire rating certificate). Suspension systems longer than 1,5 m require fireresistant insulation.

IMPORTANT:

Flexible connection between duct and S-BM2 is needed, when connected to metal duct.

The suspension of the damper must be loaded only with the weight of the damper.

The interior of the S-BM2 smoke control damper must remain accessible for maintenance,

it may be necessary to create additional inspection panels in the connecting ducts.

The maximum resistivity for in duct installation is EI120S with pressure level 2 (-1000 Pa … 300 Pa)

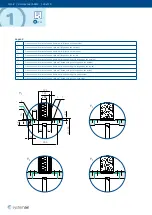

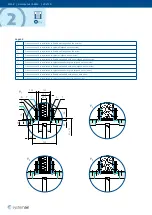

Dimension

Range

(mm)

Classification

Supporting

Construction

Construction Type/Minimal Thickness (mm)

Allowed

Blade Axis

Orientation

In the Duct

200 × 425

up to

1000 × 1225

EI90 (v

ed

i ↔ o) S1000 C

mod

MAmulti

Horizontal

duct

EN 1366-9,

EN 1366-8

EI90 (h

od

i ↔ o) S1000 C

mod

MAmulti

Vertical

duct

-

EI120 (v

ed

i ↔ o) S1000 C

mod

MAmulti

Horizontal

duct

EN 1366-9,

EN 1366-8

EI120 (h

od

i ↔ o) S1000 C

mod

MAmulti

Vertical

duct

-

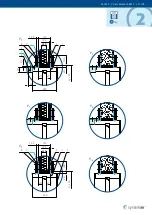

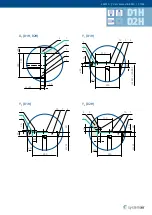

1

Smoke control damper S-BM2

3

Mineral wool filling (min. 100 kg/m³)

4

Grille

5

Nails or pins per ductwork manufacturer instructions

6

Fire resistive coating Promat K84 (Promat)

10

Connected sheet metal ductwork tested according to EN

1366-8 or EN 1366-9

Legend for figures of

Installation

11

Screw M8×35, maximum fixing torque is 8 Nm ...12 Nm

12

Mineral wool filling; thickness of mineral wool (

t

) depends on

the desired fire resistivity

13

Cover plate made of Promatect (Promat)

Y

Cutting plane

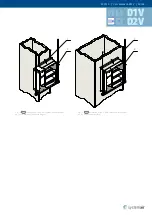

Horizontal blade axis orientation of the damper

Vertical blade axis orientation of the damper