11

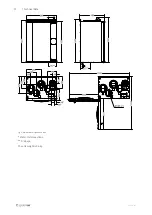

Fig. 5 External connection box and board

Position

Description

1

Connection to the main circuit board

2

Connection for external control panel (HMI) or Internet access module (IAM)

3

Modbus RS485 connection

AI6–7

Freely configurable Analog input. None/Input type selection in HMI.

DO1–4

Freely configurable digital output.

DO2 default configuration: Outdoor-/Exhaust Air Damper

DO3 default configuration: Activate Cooling

DO4 default configuration: Sum Alarm

AO3–5

Freely configurable analog output. Actuator type 0–10V, 10–0V, 2–10V, 10–2V.

AO3 default configuration: Heating (only for VTC 200/300/500/700, VTR 100/700 type models).

AO4 default configuration: Cooling

UI1–5

Freely configurable universal input. Can be set as analog input (0–10 V) or a digital input (24 V).

UI1 default configuration: Pressure guard

UI2 default configuration: Cooker hood

UI3 default configuration: Fire alarm

UI4 default configuration: Refresh

24V

Maximum current 200mA at 24VDC +-10%.

8

Before Starting the System

When the installation is completed, check that:

• The unit is installed in accordance with the instructions

• Outdoor and exhaust air dampers and silencers are installed and that the duct system is correctly connected to the

unit

• All ducts are sufficiently insulated and installed according to local rules and regulations

• Outdoor air intake is positioned with sufficient distance to pollution sources (kitchen ventilator exhaust, central vac-

uum system exhaust or similar)

• All external equipment is connected

• The unit is correctly wired

9

Commissioning

Follow the first startup instructions and fill in the

Commissioning record

as you go through the settings.

The Startup Wizard cannot be skipped.

254496 | v01