Page 11

English

Transport, Lifting and Positioning

3 TRANSPORT, LIFTING AND

POSITIONING

Refrigerators are supplied assembled (apart from

standard antivibrating rubber supports, that will be

installed on site). The equipment are full of refrigerant

and oil, in the quantity required for a proper opera-

tion.

3.1 Inspection

When the unit is delivered, it is recommended to check

it carefully and to identify any damage occurred dur-

ing transportation. The goods are shipped ex-factory,

at the buyer’s risk. Check that the delivery includes all

the components listed in the order.

In case of damage, note it down on the carrier’s deliv-

ery note and issue a claim according to the instructions

provided in the delivery note.

In the presence of any serious damage, that does not

affect the surface only, it is recommended to inform

manufacturer immediately.

Please note that manufacturer may not be held liable

for any damage to the equipment during transporta-

tion, even though the carrier has been appointed by

the factory.

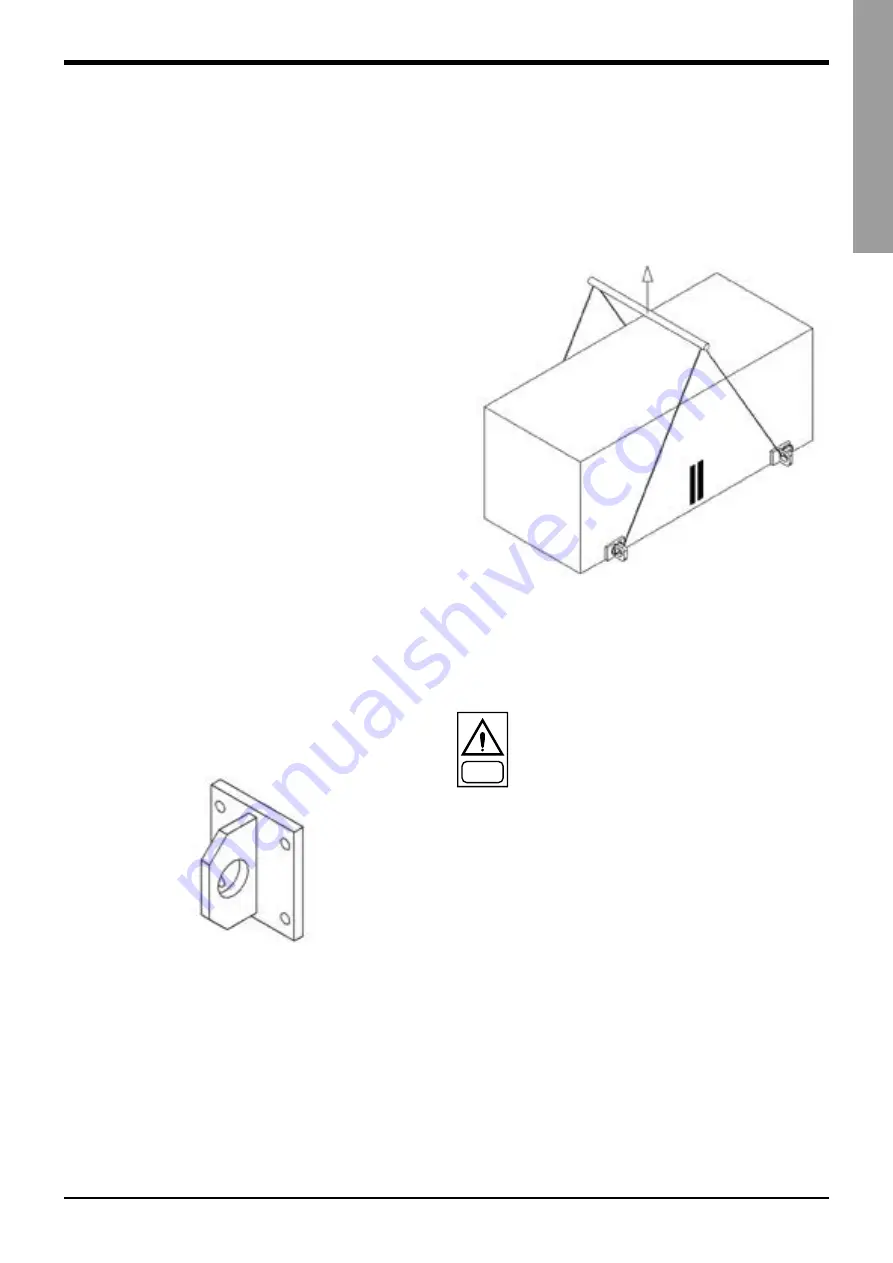

3.2 Lifting

The unit must be lifted by using the hooks inserted into

the relevant eyebolts (see the figure).

WARNING

It is recommended to use a spacer to prevent cables

from damaging the unit (see the figure).

Before positioning the unit, make sure that the place of

installation is appropriate and sturdy enough to hold

the weight and to withstand the stress caused by the

operation of the whole assembly.

Do not displace the unit on rollers, and do

not lift it with a lift truck.

Unit must be lifted carefully.

To lift unit slowly and regularly.

To lift and displace the unit:

n

Insert and secure eyebolts into the holes marked on

the frame.

n

Insert spacer between cables.

n

Hook near the barycentre of the unit.

n

The cables must be long enough to form, if ten-

sioned, an angle of at least 45° with respect to the

horizontal plane.