Page 14

4.3 External hydraulic circuit

The flow switch and the filter water, although not in-

cluded in the supply, must always be fitted such as

plant components.

Their installation is mandatory for warranty.

The external hydraulic circuit must ensure

the water flow to the evaporator under any

working or adjustment conditions.

The external hydraulic circuit should consist of the fol-

lowing elements:

n

A circulation pump that can ensure the necessary

capacity and discharge head.

n

The capacity of the primary hydraulic circuit should

not be less than 7.5 litres/KW of cooling capacity,

in order to prevent the repeated startup of the com-

pressor and any damage to it. If the water capacity

in the primary piping of the circuit and in the evapo-

rator is lower than this value, an insulated storage

tank shall be installed.

n

A membrane expansion vessel provided with safety

valve with vent, that must be visible.

The capacity of the expansion vessel must

allow for an expansion of at least 2% of the

volume of the fluid in the circuit (evaporator,

piping, user circuit and standby tank, if any).

The expansion vessel needs not be isolated,

because no water can circulate inside it.

n

A flow switch, to disable the appliance when the

water is not circulating.

The flow switch must be connected (terminals

1-2) as shown in the wiring diagram of the

“User’s Terminal Box” (Paragraph 4.7).

To install the flow switch, follow the man-

ufacturer’s instructions.

As a general rule, the flow switch shall be mounted on

a horizontal pipe, at a distance from the curves equal

to 10 times the diameter of the pipe and far from

valves or other components that are likely to hinder the

water flow upstream of or downstream from the flow

switch.

n

The bleed valves must be mounted on the highest

point of the piping.

n

The stop valves must be mounted on the piping of

the water entering/leaving the condenser.

n

The discharge points (provided with plugs, cocks

etc.) must be arranged in the lowest point of the pip-

ing.

WARNING

NOTE

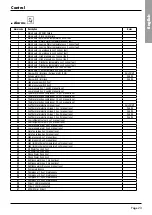

RECOMMENDED WATER COMPOSITION

PH

7,5 - 9

Electrical conductivity

10 - 500

μS/cm

Total hardness

4,5 - 8,5

dH

Temperature

< 60

[°C]

Alkalinity (HCO

3

-

)

70-300

ppm

Alkalinity / Sulphates (HCO

3

-

/ SO

4

2-

)

> 1

ppm

Sulphates (SO

4

2-

)

< 70

ppm

Chlorides (Cl

-

)

< 50

ppm

Free Chlorine

< 0,5

ppm

Phosphates (PO

4

3-

)

< 2

ppm

Ammonia (NH

3

)

< 0,5

ppm

Ammonium Ion (NH

4

+

)

< 2

ppm

Manganese Ion (Mn

2+

)

< 0,05

ppm

Free Carbon Dioxide (CO

2

)

< 5

ppm

Hydrogen Sufide (H

2

S)

< 0,05

ppm

Oxygen Content

< 0,1

ppm

Nitrates (NO

3

-

)

< 100

ppm

Manganese (Mn)

< 0,1

ppm

Iron (Fe)

< 0,2

ppm

Aluminium (Al)

< 0,2

ppm

Caution

If the water circuit is to be drained for a time exceeding one month, the circuit must

be fully charged with nitrogen to prevent any risk of corrosion by differential venting

Installation

3)Check AVM’s heights refers to assembly’s instruc-

tions enclosed to the accesory and regulate it using

an adeguate spanner.

4)Lock in position with washer and low nut.

At the end of this operation, make sure the machine

is elastic on the axes and compensating antivibration

joints can be fitted in the water connections.

WARNING