Page 19

English

5 START-UP

The unit must be started for the first time by

personnel suitably trained by one Authorised

Service Centre. Failure to meet this require-

ment will immediately void the warranty.

The operations carried out by authorised

personnel are limited to the start-up of the

unit, and do not include any other operation

on the plant, such as, for example, electrical

and hydraulic connections etc. All the other

operations before start-up, including oil pre-

heating for at least 12 hours, must be per-

formed by the Installer.

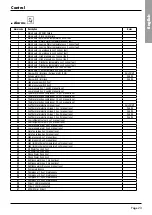

5.1 Preliminary check

The checks listed below shall be performed before

starting the unit and before the arrival of the personnel

authorised.

n

Check the section of power supply and grounding

cables; make sure that terminals are tightened and

check the correct operation of contactors, with the

main switch open.

n

Check that any voltage and phase variation in the

power supply does not exceed the prefixed thresh-

olds.

n

Connect the contacts of the flow switch and the ther-

mal relay of the pump and of the other devices (if

any), to terminals 1-2 and 3-4, respectively.

n

Check that the components of the external water

circuit (pump, user equipment, filters, power supply

tank and reservoir, if any) have been installed prop-

erly, and according to the manufacturer’s instruc-

tions.

n

Check the filling of the hydraulic circuits, and make

sure that the fluid circulation is correct, without any

trace of leaks and air bubbles. If you use ethylene

glycol as antifreeze, check that its percentage is cor-

rect.

n

Check that the direction of rotation of the pumps is

correct, and that fluids have been circulating for at

least 12 hours for both pumps. Then, clean the filters

on the suction side of the pumps.

n

Adjust the liquid distribution network in such a way

that the flow rate is within the specified range.

n

Check that the water quality is up to the specifica-

tions.

n

Check that oil heaters, if any, have been turned on

at least 12 hours before.

5.2 Start-up

Start-up sequence:

n

Turn on the Main switch (at least 12 hours before).

n

Check that the oil in the compressor has reached the

requested temperature (the minimum temperature

outside the pan must be approx. 40°C) and that the

auxiliary control circuit is energised.

n

Check the operation of all the external equipment,

and make sure that the control devices of the plant

are properly calibrated.

n

Start the pump and check that the water flow is cor-

rect.

n

Set the desired fluid temperature on the control

board.

n

Start the appliance (see Chapter 6).

n

Check the correct direction of rotation of compres-

sors. Scroll compressors cannot compress the re-

frigerant when they rotate in the opposite direction.

To make sure that they are rotating in the correct

direction, simply check that, just after the start-up

of the compressor, the pressure drops on the LP side

and rises on the HP side. Furthermore, if a scroll

compressor rotate in the opposite direction, there is

a considerable rise in the sound level of the unit, as

well as in a dramatic reduction of current absorp-

tion compared to normal values. In case of wrong

rotation, the scroll compressor can be definitely

damaged.

n

After about 15 minutes of operation check that there

are no bubbles, through the sight glass on the liquid

line.

The presence of bubbles may indicate that a

part of the refrigerant charge has been re-

leased in one or more points. It is important

to remove these leaks before proceeding.

n

Repeat the start-up procedure after removing the

leaks.

n

Check the oil level in the compressor’s sight glass.

Start-up

WARNING

NOTE

WARNING